Molded Plastics Market By Material Type (Polyethylene, Polypropylene, Polyvinyl Chloride, Polyethylene Terephthalate, Other), By Technology (Injection Molding, Blow Molding, Rotational Molding, Other), By End-Use Industry (Automotive, Packaging, Consumer Goods, Electronics, Construction, Other), By Region And Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, And Forecast 2023-2032

-

7524

-

May 2023

-

151

-

-

This report was compiled by Shreyas Rokade Shreyas Rokade is a seasoned Research Analyst with CMFE, bringing extensive expertise in market research and consulting, with a strong background in Chemical Engineering. Correspondence Team Lead-CMFE Linkedin | Detailed Market research Methodology Our methodology involves a mix of primary research, including interviews with leading mental health experts, and secondary research from reputable medical journals and databases. View Detailed Methodology Page

-

Quick Navigation

- Report Overview

- Driving factors

- Restraining Factors

- Environmental Concerns

- Fluctuations in Raw Material Prices

- Regulatory and Compliance Requirements

- Competition from Alternative Materials

- Material Type Analysis

- Technology Analysis

- End-Use Industry Analysis

- Key Market Segments

- Growth Opportunity

- Latest Trends

- Regional Analysis

- Key Players Analysis

- Recent Development

- Report Scope:

Report Overview

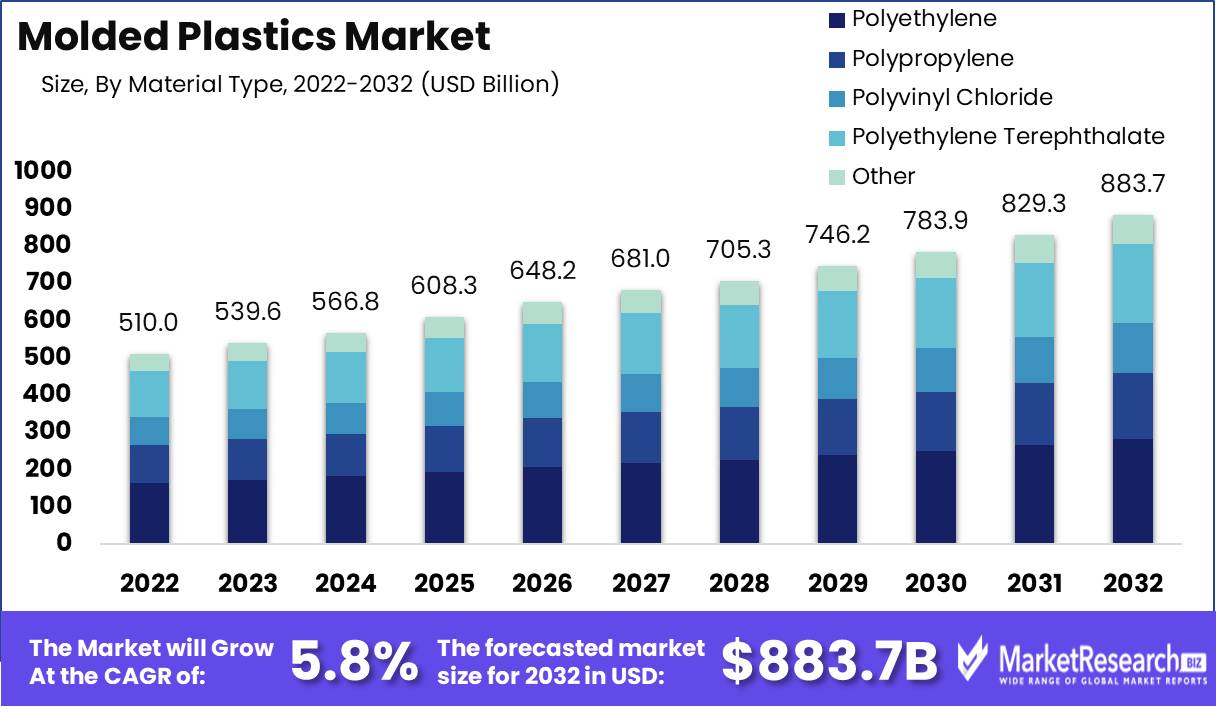

Molded Plastics Market size is expected to be worth around USD 883.7 Bn by 2032 from USD 510.0 Bn in 2022, growing at a CAGR of 5.8% during the forecast period from 2023 to 2032.

The molded plastics market is a rapidly growing industry that plays a vital role in various sectors worldwide. The molded plastics market can be defined as the production and distribution of plastic materials that have been shaped or molded into specific forms through various manufacturing processes. The primary goal of this market is to produce high-quality plastic products that meet the specific needs and requirements of different industries around the world. From automotive parts to medical devices, molded plastics find their applications in a wide range of sectors.

The importance of the molded plastics market cannot be overstated, as it offers numerous advantages over traditional manufacturing methods. One of the key advantages is cost-effectiveness, as molded plastics can be produced at a much lower cost compared to other materials such as metal or glass. Additionally, the versatility of molded plastics allows for intricate designs and complex shapes, providing manufacturers with endless possibilities for product innovation.

In recent years, the molded plastics market has witnessed notable innovations that have revolutionized the industry. Advanced manufacturing technologies, such as 3D printing and injection molding, have made it easier and faster to produce plastic products with enhanced precision and accuracy. These innovations have not only improved efficiency but also opened up new opportunities for customization in the manufacturing process.

Major investments in the molded plastics market have been seen across various sectors. Industries such as automotive, healthcare, packaging, and construction have incorporated molded plastics into their products and services to achieve greater efficiency and cost savings. The automotive industry, in particular, has significantly benefited from the use of molded plastics in the manufacturing of lightweight and fuel-efficient vehicles.

The growth of the molded plastics market can be attributed to its wide-ranging applications in various industries. From consumer goods to industrial equipment, molded plastics are used in the production of a diverse range of products. In the consumer goods sector, molded plastics are commonly used in the manufacturing of household appliances, toys, and electronic devices. In the industrial sector, they are widely used in the production of machine parts, pipes, and fittings.

Driving factors

Lightweight and Durable Materials

In today's fast-paced world, industries are constantly seeking materials that offer both durability and lightweight properties to optimize their operations. The molded plastics market has become a go-to solution due to its ability to meet these requirements effectively. Molded plastics offer exceptional strength-to-weight ratios, making them an ideal choice for various industries such as automotive, aerospace, packaging, and electronics. Industries are increasingly realizing the benefits of incorporating molded plastics in their products and solutions.

Packaging and Automotive Industries

The packaging industry plays a pivotal role in protecting and preserving products while ensuring convenience and aesthetics. As the demand for packaged goods continues to rise, driven by factors such as urbanization, changing consumer lifestyles, and e-commerce growth, the molded plastics market has witnessed a remarkable surge in demand. The packaging industry extensively utilizes molded plastics due to their versatility, cost-effectiveness, and ability to offer innovative designs. From food and beverage packaging to pharmaceutical and personal care products, molded plastics provide the necessary protection while maintaining product integrity.

Advancements in Molding Technologies

Technological advancements have revolutionized the manufacturing processes of molded plastics, leading to improved efficiency, precision, and productivity. Novel molding techniques, such as injection molding containers, blow molding machine, rotational molding powder, and thermoforming, have significantly contributed to the growth of the molded plastics market. Injection molding, being the most widely used technique, enables the production of complex and detailed molded plastic parts with high precision and consistency.

Construction and Consumer Goods

The versatility and adaptability of molded plastics have led to their growing applications in the construction and consumer goods sectors. In the construction industry, molded plastics find widespread use in pipes, fittings, windows, roofing, insulation, and flooring materials. The lightweight nature, resistance to corrosion, and ease of installation make molded plastics a preferred choice for construction projects. In the consumer goods sector, molded plastics are utilized in various everyday products, ranging from household appliances to electronic gadgets, furniture, and toys.

Sustainability and Recycling

As the world becomes more conscious of the environmental impact of plastic waste, the molded plastics market is increasingly focusing on sustainability and recycling initiatives. The industry is adopting innovative approaches to reduce plastic waste, enhance recyclability, and develop eco-friendly alternatives. Manufacturers are incorporating recycled materials in the production of molded plastics, reducing the dependence on virgin plastic resins.

Restraining Factors

Environmental Concerns

The molded plastics market has faced increasing scrutiny due to the detrimental environmental effects of plastic waste. Plastic pollution has become a significant global issue, impacting ecosystems, wildlife, and human health. Environmental awareness has led to a growing demand for sustainable alternatives, putting pressure on the molded plastics industry to adopt more environmentally friendly practices. Manufacturers in the molded plastics market are now faced with the challenge of addressing these concerns by adopting measures such as recycling, reducing waste generation, and exploring biodegradable alternatives.

Fluctuations in Raw Material Prices

Another factor to consider in the molded plastics market is the potential fluctuations in raw material prices. As a critical component of the industry, changes in the cost of raw materials can significantly impact profit margins and overall business operations. Factors such as global supply and demand, geopolitical events, and natural disasters can all contribute to price fluctuations in the raw material market. For manufacturers, these price fluctuations can pose significant challenges in terms of cost management, procurement strategies, and overall profitability.

Regulatory and Compliance Requirements

Regulatory and compliance requirements are crucial considerations for businesses operating in the molded plastics market. Governments and regulatory bodies worldwide have been implementing stricter regulations to promote sustainability, ensure product safety, and protect the environment. Complying with these regulations can be complex and may involve additional costs and time-consuming processes. Manufacturers need to stay abreast of evolving regulatory frameworks, engage in rigorous testing and certification procedures, and establish strong quality control systems to meet the compliance requirements.

Competition from Alternative Materials

While plastics have dominated the manufacturing industry for decades, the molded plastics market now faces increasing competition from alternative materials. As environmental concerns grow, consumers and businesses are actively seeking sustainable alternatives to traditional plastics. Materials such as biodegradable polymers, plant-based plastics, and composites are gaining traction as viable substitutes. The market for these alternative materials is rapidly expanding, which threatens to reduce the demand for molded plastics.

Customization and Complex Designs

The molded plastics market is diverse, catering to various industries that require customization and complex designs. However, meeting these demands can present challenges due to the inherent characteristics of plastics, such as limited flexibility and the potential for dimensional instability. Manufacturers must invest in advanced technologies, equipment, and expertise to meet customers' demands for intricate designs and customization.

Material Type Analysis

The molded plastics market is dominated by the polyethylene segment, accounting for a significant portion of the overall market share. Polyethylene is a versatile material that is widely used in various industries due to its unique properties. It offers excellent durability, flexibility, and strength, making it an ideal choice for manufacturing molded plastic products.

Consumer trends and behavior towards the polyethylene segment have also played a crucial role in its dominance in the molded plastics market. Consumers are increasingly looking for sustainable and eco-friendly packaging solutions. Polyethylene offers excellent recyclability, which aligns with the growing demand for environmentally friendly products. Additionally, polyethylene products are lightweight and provide excellent protection, making them highly preferred by consumers.

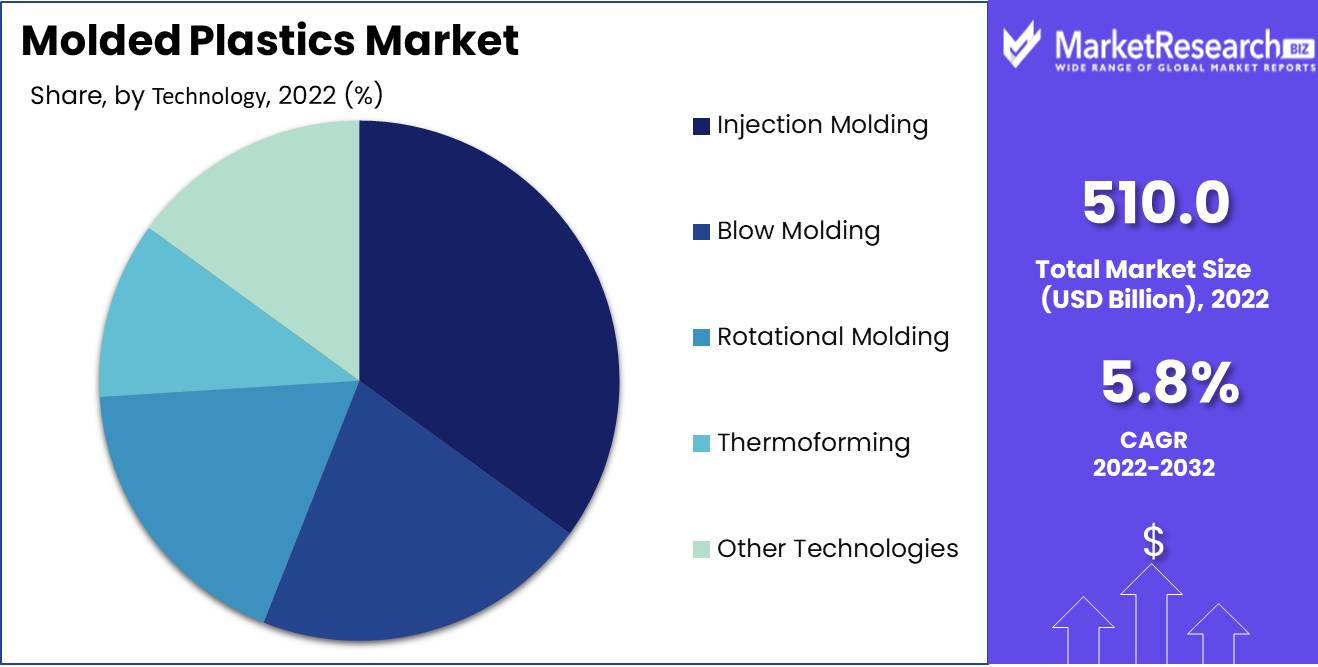

Technology Analysis

The injection molding segment dominates the molded plastics market, mainly due to its efficiency and versatility in producing a wide range of plastic products. Injection molding is a manufacturing process that involves injecting molten plastic into a mold cavity. This process enables mass production of complex-shaped plastic products with high precision and accuracy.

Consumer trends and behavior towards the injection molding segment are influenced by the growing demand for customized and personalized products. Injection molding allows manufacturers to produce intricate designs and unique shapes that meet the specific requirements of consumers. Additionally, the durability and quality of injection-molded products have gained popularity among consumers, further boosting the growth of the segment.

End-Use Industry Analysis

The packaging segment dominates the molded plastics market, accounting for a significant share of the overall market. Packaging plays a crucial role in various industries, including food and beverages, pharmaceuticals, and consumer goods. Molded plastics offer excellent protection, durability, and design flexibility, making them an ideal choice for packaging applications.

Consumer trends and behavior towards the packaging segment are influenced by the increasing preference for convenience and sustainability. Consumers are demanding packaging solutions that are easy to use, visually appealing, and environmentally friendly. Molded plastic packaging offers various benefits such as lightweight, resealability, and recyclability, aligning with the consumer preferences and driving the growth of the segment.

Key Market Segments

By Material Type

- Polyethylene

- Polypropylene

- Polyvinyl Chloride

- Polyethylene Terephthalate

- Other Material Types

By Technology

- Injection Molding

- Blow Molding

- Rotational Molding

- Thermoforming

- Other Technologies

By End-Use Industry

- Automotive

- Packaging

- Consumer Goods

- Electronics

- Construction

- Other End-Use Industries

Growth Opportunity

Advancing Sustainable Solutions

Amid growing environmental concerns, the demand for bio-based and biodegradable molded plastics has witnessed a significant surge. Consumers are increasingly seeking sustainable alternatives to conventional plastics, which has paved the way for innovative solutions. Manufacturers can capitalize on this trend by investing in research and development to develop bio-based and biodegradable materials while ensuring similar or even enhanced performance characteristics. This move not only aligns with environmental goals but also attracts eco-conscious consumers, opening up new avenues of growth for the molded plastics market.

Exploring Untapped Emerging Markets

Expanding into emerging markets with ongoing infrastructure development presents a promising opportunity for the molded plastics market. Rapid urbanization, industrialization, and rising disposable incomes in these markets create a burgeoning demand for molded plastics. Industries such as automotive, packaging, and construction, which heavily rely on molded plastics, are witnessing remarkable growth in these regions. By strategically entering these markets and establishing partnerships with local manufacturers, companies can unlock new revenue streams and significantly expand their market presence.

Harnessing the Power of Collaboration

Innovation drives growth and offers a competitive edge in the molded plastics market. Collaborating with manufacturers and end-users can foster product innovation by leveraging collective expertise and resources. By actively engaging with various stakeholders, including material suppliers, manufacturers, and customers, companies can gain valuable insights into evolving market needs and challenges. This collaborative approach facilitates the development of tailor-made solutions, customization, and the ability to meet specific requirements.

Embracing Circular Economy Practices

The adoption of recycled and circular economy practices represents a significant opportunity for the molded plastics market. By integrating a closed-loop system into their operations, manufacturers can minimize waste, conserve resources, and reduce their environmental footprint. Incorporating recycled plastics in the production process and encouraging end-users to participate in recycling programs can create a sustainable supply chain and enhance brand reputation.

Differentiation and Cost Competitiveness

In a highly competitive market, product differentiation and cost competitiveness play a vital role in gaining a competitive edge. By investing in research and development, manufacturers can create unique, value-added products that cater to specific customer segments. This differentiation allows companies to offer customized solutions, addressing industry-specific challenges and requirements. Simultaneously, optimizing production processes, streamlining supply chains, and investing in advanced technologies can enhance cost competitiveness.

Latest Trends

Packaging and Automotive Components

Injection molding has emerged as a leading technology for producing complex plastic components with high precision and efficiency. With the increasing demand for lightweight, durable, and cost-effective packaging solutions, companies are turning to injection-molded plastics to meet consumer expectations. The versatility of this process enables the production of various packaging designs, including bottles, containers, and caps, allowing businesses to showcase their products in an attractive and functional manner.

Thermoformed Plastics

In addition to injection molding, thermoforming has gained immense popularity in various industries, including consumer goods and healthcare. This manufacturing process involves heating a plastic sheet and forming it into a desired shape using pressure or vacuum. Thermoformed plastics offer exceptional design freedom, making them an ideal choice for creating unique and appealing packaging solutions. In the consumer goods sector, thermoformed plastics are widely used to create product packaging with eye-catching designs and sturdy protection.

3D Printing and Additive Manufacturing

The emergence of 3D printing and additive manufacturing technologies has revolutionized the way complex plastic parts are designed and produced. This innovative approach allows for the creation of intricate geometries that were previously challenging or even impossible to manufacture using traditional methods. 3D printing opens up new possibilities for customization, prototyping, and rapid production, enabling businesses to realize their ideas at a much faster pace. The benefits of 3D printing extend beyond just complex shapes and customization.

Recycled and Sustainable Plastics

In response to growing environmental concerns, there is a strong push towards the adoption of recycled and sustainable plastics. Governments, organizations, and consumers are increasingly demanding eco-friendly alternatives to traditional plastics, driving manufacturers to explore innovative solutions. The development of recycling technologies and the use of bio-based materials hold great potential in reducing the environmental impact of plastic production and disposal. Recycled plastics not only contribute to waste reduction but also offer similar performance characteristics as virgin plastics.

Lightweight and High-Performance Plastics

With an ongoing emphasis on fuel efficiency and energy conservation, various industries are increasingly turning to lightweight and high-performance plastics. The transportation sector, including automotive, aerospace, and railway, is specifically leveraging these advanced materials to reduce overall weight and improve vehicle performance. By replacing traditional metals with lightweight plastics, companies can achieve substantial fuel savings, lower emissions, and enhance overall sustainability.

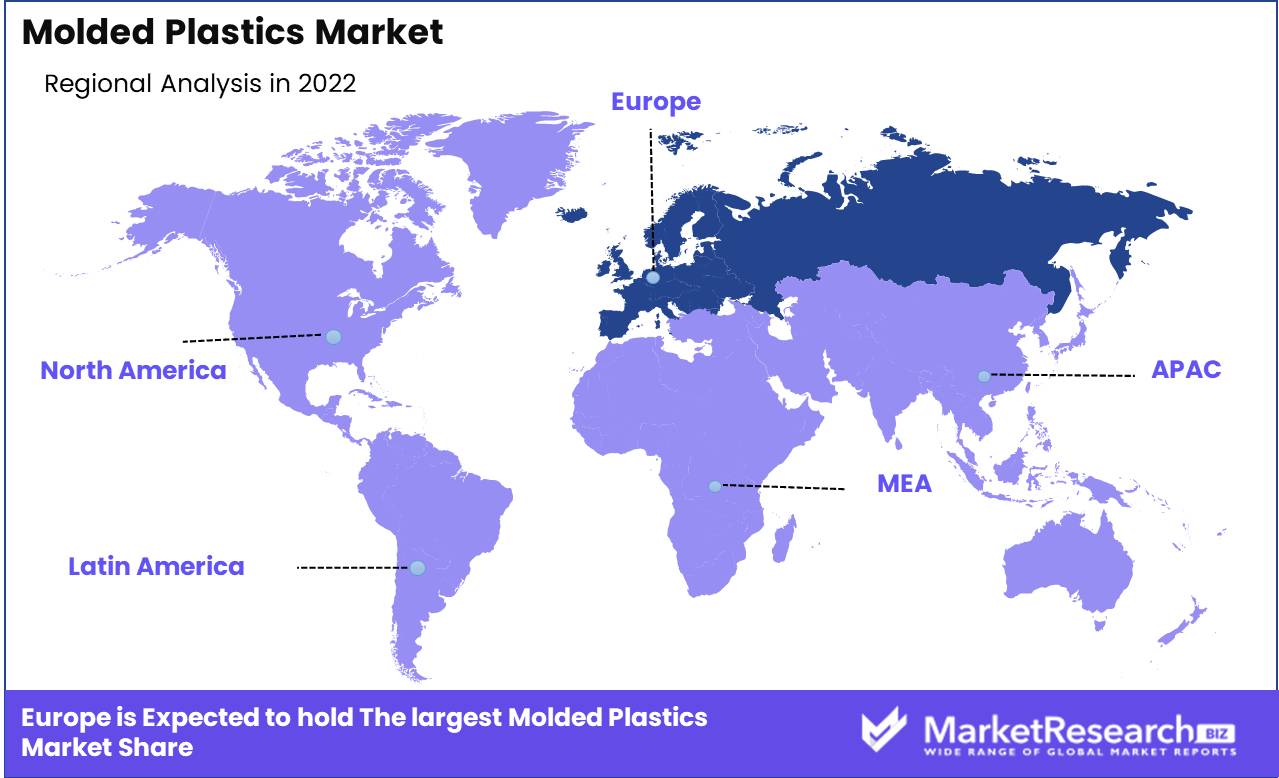

Regional Analysis

Asia-Pacific Region Dominates the Molded Plastics Market. In the fast-paced world of plastics manufacturing, the Asia-Pacific region has emerged as the leader in molded plastics, spearheading innovation and driving market growth. With a combination of advanced technologies, skilled labor, and favorable economic conditions, Asia-Pacific has cemented its position as the go-to destination for businesses seeking to invest in and expand their operations in the molded plastics industry.

The Asia-Pacific region encompasses a vast geographical area, including countries like China, Japan, India, and South Korea. Each of these countries plays a significant role in driving the region's dominance in the molded plastics market. Let's explore the key factors that contribute to this dominance and understand why Asia-Pacific reigns supreme.

First and foremost, the Asia-Pacific region boasts a massive consumer base, with a rapidly growing middle class. This surge in population and disposable income has fueled the demand for a wide range of consumer goods, including packaging materials, household products, automotive components, and electronics. As a result, manufacturers are increasingly focused on producing high-quality molded plastics to meet the evolving needs of the market.

Asia-Pacific is home to some of the world's largest manufacturers of plastics and machinery, facilitating seamless integration across the entire value chain. These manufacturers leverage advanced technologies and automation to produce large volumes of complex molded plastic components efficiently. The region's robust infrastructure development and access to raw materials further enhance its manufacturing capabilities, attracting both domestic and international investments.'

Key Regions and Countries

North America

- US

- Canada

- Mexico

Western Europe

- Germany

- France

- The UK

- Spain

- Italy

- Portugal

- Ireland

- Austria

- Switzerland

- Benelux

- Nordic

- Rest of Western Europe

Eastern Europe

- Russia

- Poland

- The Czech Republic

- Greece

- Rest of Eastern Europe

APAC

- China

- Japan

- South Korea

- India

- Australia & New Zealand

- Indonesia

- Malaysia

- Philippines

- Singapore

- Thailand

- Vietnam

- Rest of APAC

Latin America

- Brazil

- Colombia

- Chile

- Argentina

- Costa Rica

- Rest of Latin America

Middle East & Africa

- Algeria

- Egypt

- Israel

- Kuwait

- Nigeria

- Saudi Arabia

- South Africa

- Turkey

- United Arab Emirates

- Rest of MEA

Key Players Analysis

The market for molded plastics is competitive as demand for plastics worldwide rises. Global leaders are fighting to dominate this market. China Petroleum Corporation, Solvay S.A, Eastman Chemical Company, Formosa Plastics Group (FPG), Chevron Corporation, and Versalis are among the notable firms impacting the molded plastics market.

Sinopec is a Chinese state-owned oil and gas business. One of the world's largest integrated energy and chemical enterprises. Sinopec dominates the molded plastics market due to its petrochemical sector. The company makes polyethylene, polypropylene, polyester, and polystyrene molded plastics. Sinopec's large manufacturing capacity and considerable R&D have made it a major industry player.

Belgian chemical manufacturer Solvay S.A. makes innovative materials and speciality chemicals. The company supplies molded plastics to automotive, aerospace, and healthcare industries. Solvay's high-performance polymers and composite materials provide them a competitive edge. Sustainability and environmental responsibility boost the company's molded plastics market position.

American multinational Eastman Chemical Company produces speciality chemicals, innovative materials, and textiles. The company is a major player in the molded plastics market, providing resins and plasticizers for packaging, automotive, construction, and consumer goods applications. Eastman Chemical Company stays ahead of the competition by focusing on innovation and sustainability.

Taiwanese conglomerate Formosa Plastics Group (FPG) makes petrochemicals, plastics, and steel. FPG produces PVC, PE, PP, and PS molded plastics. Their global customer base is due to their enormous distribution network and manufacturing skills. FPG's dedication to quality and innovation has made it a leading molded plastics manufacturer.

Chevron Phillips Chemical Company, a subsidiary of Chevron Corporation, is a major player in the molded plastics market. The company supplies speciality chemicals and plastics to packaging, automotive, and electronics industries. Chevron's global reach and outstanding R&D have made it an industry leader.

Eni owns Versalis, a chemical firm. Versalis, an elastomer expert, has contributed to the molded plastics market. The company's sustainable solutions and technology developments have attracted clients from automotive, construction, and consumer goods industries. Versalis' research, innovation, and constant improvement have helped it dominate the molded plastics business.

Top Key Players in Molded Plastics Market

- China Petroleum Corporation

- Solvay S.A

- Eastman Chemical Company

- Formosa Plastics Group (FPG)

- Chevron Corporation

- Versalis

- BASF SE

- Hanwha Group

- Reliance Industries

- Westlake Chemical

- Haldia Petrochemicals

- AGC Chemicals

- Chemours Company.

Recent Development

- In 2023, Stratasys revealed its groundbreaking 3D-printed molded plastics. This groundbreaking series is precisely designed to combine greater durability with exceptional lightweight qualities, opening up new applications. Stratasys wants to offer cost-effective manufacturing and increased performance to industries across sectors, solidifying its market leadership.

- In 2022, Covestro announced a bold strategy to increase molded plastics production in China to satisfy rising demand. Covestro will serve automotive, electronics, and healthcare industries in the Asian market with this strategic move. Covestro wants to boost supply chain efficiency and local market assistance in this critical region to cement its status as a trusted partner.

- In 2021, Sabic's announcement addresses the widespread demand for sustainable solutions. Sabic will launch a breakthrough line of recyclable molded plastics, reducing the environmental impact of plastic items. This Sabic commitment promotes a circular economy in molded plastics by using eco-friendly materials without sacrificing performance.

- In 2020, BASF made waves by acquiring Solvay's molded plastics business. BASF's market dominance and technological capabilities are strengthened by this move. BASF can better serve a variety of industries by addressing changing customer needs and unlocking new innovation potential with Solvay's business.

Report Scope:

Report Features Description Market Value (2022) USD 510.0 Bn Forecast Revenue (2032) USD 883.7 Bn CAGR (2023-2032) 5.8% Base Year for Estimation 2022 Historic Period 2016-2022 Forecast Period 2023-2032 Report Coverage Revenue Forecast, Market Dynamics, COVID-19 Impact, Competitive Landscape, Recent Developments Segments Covered By Material Type (Polyethylene, Polypropylene, Polyvinyl Chloride, Polyethylene Terephthalate, Other Material Types)

By Technology (Injection Molding, Blow Molding, Rotational Molding, Thermoforming, Other Technologies)

By End-Use Industry (Automotive, Packaging, Consumer Goods, Electronics, Construction, Other End-Use Industries)Regional Analysis North America – The US, Canada, & Mexico; Western Europe – Germany, France, The UK, Spain, Italy, Portugal, Ireland, Austria, Switzerland, Benelux, Nordic, & Rest of Western Europe; Eastern Europe – Russia, Poland, The Czech Republic, Greece, & Rest of Eastern Europe; APAC – China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Malaysia, Philippines, Singapore, Thailand, Vietnam, & Rest of APAC; Latin America – Brazil, Colombia, Chile, Argentina, Costa Rica, & Rest of Latin America; Middle East & Africa – Algeria, Egypt, Israel, Kuwait, Nigeria, Saudi Arabia, South Africa, Turkey, United Arab Emirates, & Rest of MEA Competitive Landscape China Petroleum Corporation, Solvay S.A, Eastman Chemical Company, Formosa Plastics Group (FPG), Chevron Corporation, Versalis, BASF SE, Hanwha Group, Reliance Industries, Westlake Chemical, Haldia Petrochemicals, AGC Chemicals, and Chemours Company. Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) -

-

- China Petroleum Corporation

- Solvay S.A

- Eastman Chemical Company

- Formosa Plastics Group (FPG)

- Chevron Corporation

- Versalis

- BASF SE

- Hanwha Group

- Reliance Industries

- Westlake Chemical

- Haldia Petrochemicals

- AGC Chemicals

- Chemours Company.