Hydraulic Cylinder Market By Application (Industrial Equipment, Mobile Equipment), By End User (Aerospace and Defense, Oil and Gas, Agriculture, And Others), By Product (Tie-Rod Cylinders, Welded Cylinders, Telescopic Cylinders,And Others), By Functionality (Single Acting Cylinders, Double Acting Cylinders, Multi-Stage/Tandem), By Bore Size (Less Than 50 mm, 51 mm to 100 mm, 101 mm to 150 mm, Greater Than 151 mm), By Region And Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, And Forecast 2023-2032

-

25519

-

March 2023

-

166

-

-

This report was compiled by Kalyani Khudsange Kalyani Khudsange is a Research Analyst at Prudour Pvt. Ltd. with 2.5 years of experience in market research and a strong technical background in Chemical Engineering and manufacturing. Correspondence Sr. Research Analyst Linkedin | Detailed Market research Methodology Our methodology involves a mix of primary research, including interviews with leading mental health experts, and secondary research from reputable medical journals and databases. View Detailed Methodology Page

-

Quick Navigation

Report Overview

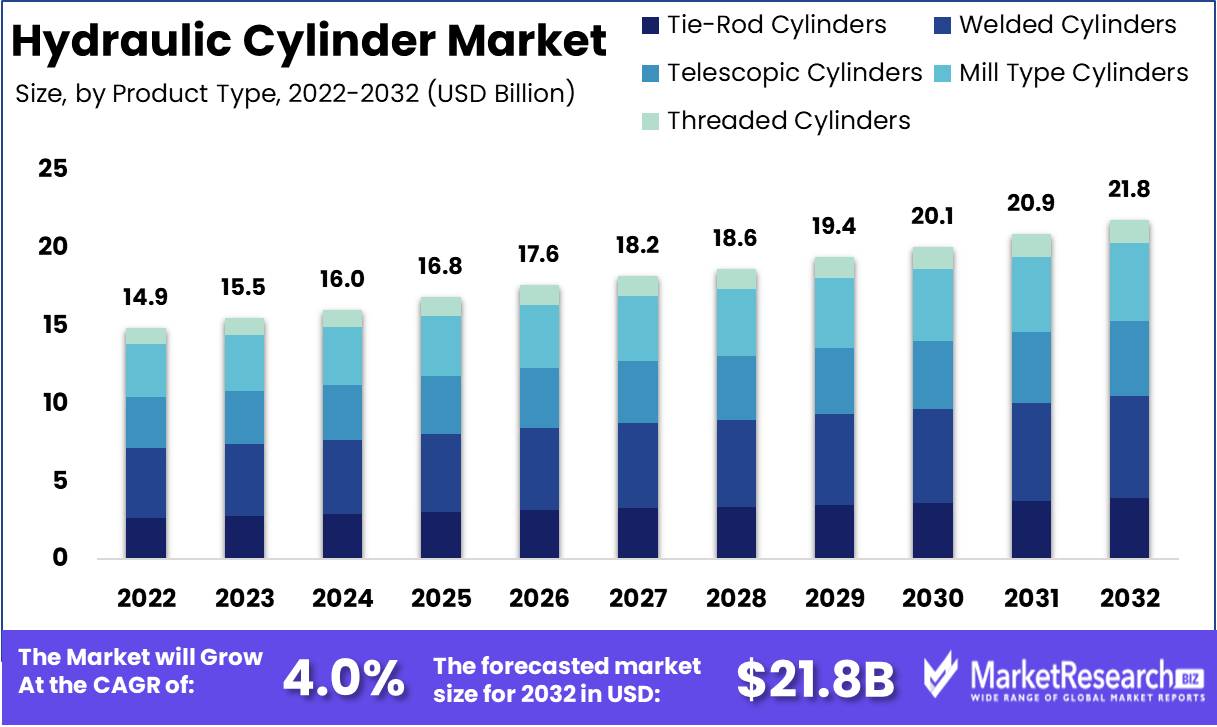

Hydraulic Cylinder Market size is expected to be worth around USD 22.02 Bn by 2032 from USD 14.88 Bn in 2022, growing at a CAGR of 4.0% during the forecast period from 2023 to 2032.

This report explores in depth the many facets of the hydraulic cylinder market, including its definition and objectives, significance and advantages, notable innovations, major investments, growth and applications, industries investing in the market, major drivers, ethical concerns, responsible use, and business applications, with a focus on transparency, explicability, and accountability.

Hydraulic Cylinders Market is a fiercely competitive and rapidly expanding industry, as it involves the production and distribution of hydraulic cylinders to a variety of global industries. Hydraulic cylinders play a crucial role in the generation of linear motion by converting hydraulic pressure to mechanical force. Due to the growing demand for sophisticated apparatus and equipment in a variety of industries, the hydraulic cylinder market has continued to expand and attracted substantial research and development investments.

The hydraulic cylinder market refers to the production, distribution, and sale of hydraulic cylinders, which are indispensable components used across industries to generate linear force and motion. The ultimate objective of Hydraulic Cylinders Market is to provide efficient and effective solutions to industries that require hydraulic systems and to develop high-quality products that adhere to industry standards.

The hydraulic cylinder market is vital to several industries, including construction, aerospace, automotive, and marine, because hydraulic cylinders offer a compact and efficient way to generate high linear force, which is essential for heavy-duty applications. In addition, hydraulic systems offer numerous advantages over other systems, including precise control, high power density, and low maintenance costs.

Recent developments on the hydraulic cylinder market have included the introduction of smart hydraulic cylinders, which integrate sophisticated sensors and internet connectivity to enable remote monitoring and control. In addition, cutting-edge innovations include the development of high-performance actuation systems, compact and lightweight cylinders, and the use of advanced materials, such as reinforced polymers and composites, to increase durability and decrease weight.

In recent years, research and development expenditures on hydraulic cylinders have increased significantly, as an increasing number of businesses integrate hydraulic cylinders into their products and services to provide added value to their customers. In addition, some companies are investing heavily in the production of innovative hydraulic cylinders that meet the specific requirements of their consumers, which has given them a market advantage. Innovative gas cylinders are revolutionizing the hydraulic cylinder market, offering enhanced efficiency and reliability in various industrial applications.

Driving factors

Heavier Construction and Mining Operations

Hydraulic cylinders have become indispensable for heavy-duty tasks such as excavating, digging, hauling, and pressing, and have primarily benefited the construction and mining industries. Hydraulic cylinders provide the required force and accuracy for such tasks, making them the optimal choice for these industries. As these industries continue to expand, there will be an increase in demand for hydraulic cylinders.

Equipment for Material Handling and Agriculture

To effortlessly elevate and transfer heavy loads, material handling equipment such as cranes and forklifts rely heavily on hydraulic cylinders. Similarly, hydraulic cylinders are utilized extensively in agricultural machinery for applications such as tillage, harvesting, and sprinkling. The rising demand for this type of apparatus is driving the demand for hydraulic cylinders to rise.

Equipment for Energy Generation and Clean Energy Production

Power generation equipment, such as turbines and generators, requires hydraulic cylinders to function properly. As the world moves toward the production of renewable energy, hydraulic cylinders are expected to play a crucial role in the industry. Consequently, demand for hydraulic cylinders is likely to increase in this industry.

Demand for Automation and Robotics

Automation and automation are becoming more prevalent in a variety of industries, including the automotive and aerospace sectors, where hydraulic cylinders are widely used for precise movement and control. As these industries continue to develop, there will be a substantial increase in demand for hydraulic cylinders.

Changes in Regulations and Emerging Technologies

New regulations proposed by regulatory bodies may have an effect on Hydraulic Cylinders Market. The development of lightweight yet durable materials and 3D printing are anticipated to have a positive effect on the market. Nonetheless, unconventional power transmission technologies, such as electromechanical motors, may pose a threat to the market.

Consumer Behavior and Predictive Maintenance

Emerging trends such as remote monitoring and predictive maintenance are anticipated to impact consumer behavior and may have an effect on Hydraulic Cylinders Market. In the future years, these trends are likely to increase demand for hydraulic cylinders. In the near future, Hydraulic Cylinders Market is anticipated to expand significantly due to the aforementioned factors.

Restraining Factors

Extremely Expensive Maintenance and Repairs

Cylinders are essential to the effective operation of hydraulic systems because they are a fundamental component. However, Hydraulic Cylinders Market is characterized by numerous factors that present significant obstacles and restrain its expansion. The exorbitant costs associated with maintenance and restorations are a major factor restraining Hydraulic Cylinders Market.

To ensure optimal functionality, hydraulic cylinders require routine maintenance, and damages necessitate restorations that can be prohibitively expensive. Customers may delay maintenance and repairs if maintenance and repair costs escalate and become prohibitively expensive, particularly in heavy-duty applications. This delay can result in diminished performance and premature cylinder failure, ultimately impacting market growth.

Environmental Concerns

Environmental concerns have recently garnered considerable attention on a global scale, with numerous stakeholders taking measures to reduce their environmental impact. Carbon emissions are the primary environmental concern in the hydraulic cylinder market.

Hydraulic systems are known to produce significant carbon emissions, especially when operating at high pressure or load. This environmental concern is especially problematic in industries that extensively rely on hydraulic systems, such as heavy machinery manufacturing and industrial manufacturing. Customers are consequently more likely to seek out alternative technologies that generate fewer carbon emissions or retrofit their equipment to reduce their carbon footprint.

The Introduction of Electric Actuators

Alternative technologies, such as electric actuators, have had a significant impact on Hydraulic Cylinders Market. Electric actuators are more environmentally friendly than hydraulic cylinders because they emit less carbon dioxide and require less maintenance.

In addition, electric actuators are more efficient because they don't require hydraulic fluid, making them ideal for use in complex apparatus that can operate at any angle. Customers are more likely to choose electric actuators in applications where sustainability is of utmost importance, given that sustainability is a key concern in contemporary industries.

Variations in the Cost of Raw Materials

Raw materials account for a significant portion of the total cost of hydraulic cylinders. However, basic material prices are liable to unpredictable fluctuations based on a variety of economic factors including supply and demand, geopolitical events, and natural disasters.

These fluctuations in the prices of basic materials can have a substantial impact on the profitability of manufacturers, as they increase costs and reduce margins. Therefore, manufacturers must manage their supply chains with care to accommodate these fluctuations and maintain market competitiveness.

By Product Analysis

The segment of welded cylinders has a larger market share than the other varieties of hydraulic cylinders. The welded cylinders are constructed by welding the end covers to the barrel and then grinding the seams to create a seamless exterior. This procedure produces a compact and durable hydraulic cylinder.

End-users of welded hydraulic cylinders, such as manufacturers of heavy machinery, favor welded cylinders due to their compact and robust design features, which provide enhanced weight distribution and power. The segment of welded cylinders is anticipated to grow rapidly in the coming years, based on current trends. The growth is anticipated to be driven by the increase in infrastructure development in emerging economies and the resulting rise in demand for industrial apparatus.

By Functionality Analysis

Hydraulic Cylinders Market is dominated by the segment of single acting cylinders, which accounts for the majority of market share. This segment is favored due to its streamlined construction and operational simplicity. Functionally, the single acting cylinder utilizes the pressure generated by a hydraulic pump to extend or retract a piston within a cylinder, thereby producing unidirectional force.

Due to its lower cost, simplified design, and simplicity of maintenance, the segment of single-acting cylinders has become popular. End-users, such as construction and industrial equipment operators, typically choose the single-acting cylinder variant because it satisfies their functional requirements at a low price. In the foreseeable future, the segment of hydraulic cylinders for single-acting cylinders is anticipated to maintain its position as the fastest-growing segment. It is anticipated that its functional ease and low price will continue to drive demand.

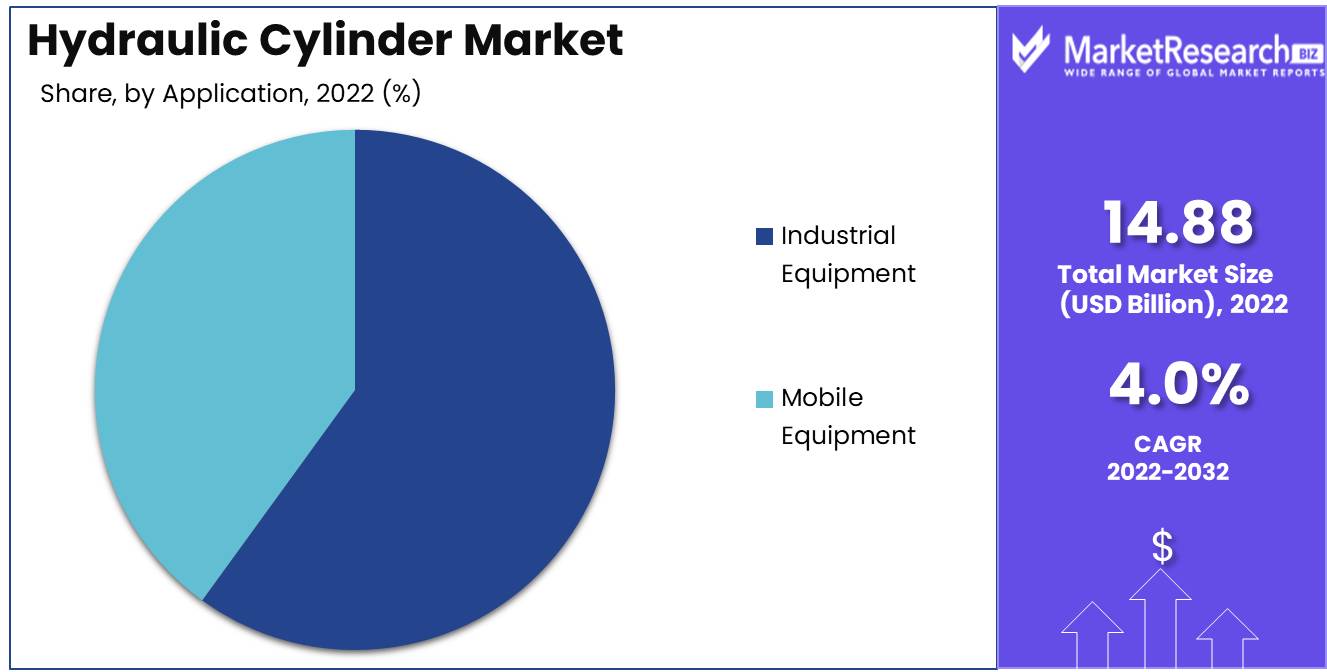

By Application Analysis

Hydraulic Cylinders Market is dominated by the industrial equipment segment. The demand for hydraulic cylinders, which are widely used in industrial equipment such as cranes, bulldozers, and automated machinery, is projected to increase over the forecast period.

To maintain production flow, industrial equipment end-users such as manufacturers and producers require robust and dependable hydraulic cylinders. They therefore choose hydraulic cylinders with high-pressure capabilities and minimal maintenance needs. In the coming years, industrial equipment is expected to dominate Hydraulic Cylinders Market, according to projections. The need for contemporary industrialization and the sustained growth of emerging economies will drive the demand for these hydraulic cylinders.

By End User Analysis

In the hydraulic cylinder market, the construction segment is dominant. The construction industry relies extensively on hydraulic cylinders, specifically for earthmoving and excavation equipment. Consequently, hydraulic cylinders are essential to the design, development, and functionality of construction machinery.

End-users in the construction industry prefer low-maintenance, high-pressure hydraulic cylinders to reduce truck, machine, and work downtimes while maintaining low operational costs. On the basis of current trends, it is anticipated that the construction segment of the hydraulic cylinder market will expand at a faster rate, primarily due to urbanization and infrastructure development initiatives.

Key Market Segments

Product

- Tie-Rod Cylinders

- Welded Cylinders

- Telescopic Cylinders

- Mill Type Cylinders

- Threaded Cylinders

Functionality

- Single Acting Cylinders

- Double Acting Cylinders

- Multi-Stage/Tandem

Bore size

- Less Than 50 mm

- 51 mm to 100 mm

- 101 mm to 150 mm

- Greater Than 151 mm

Application

- Industrial Equipment

- Mobile Equipment

End User

- Aerospace and Defense

- Oil and Gas

- Agriculture

- Material Handling

- Automotive

- Construction

- Mining

- Marine

- Others

Growth Opportunity

Demand for Hydraulic Cylinders is Growing

Emerging economies, including but not limited to China, India, and Brazil, are currently experiencing a boom in their industrial sector, resulting in a rise in demand for hydraulic cylinders in these regions. Massive investments in infrastructure development projects such as highways, railways, and airports necessitate the use of massive construction apparatus and machinery. As a fundamental component of these machines, hydraulic cylinders play a crucial role in their efficient operation, sustaining their demand in these emerging economies.

Growing Trend of Robotics and Automation

As businesses seek to increase efficiency and productivity, the automation and robotics industry has experienced a rapid expansion in recent years. It is anticipated that this upward trend will continue as industries incorporate increasingly advanced technologies such as machine learning and artificial intelligence. Hydraulic cylinders play a crucial role in automated and robotic systems, and as the industry expands, demand for hydraulic cylinders is expected to increase exponentially.

Development of the renewable energy industry

In an effort to reduce their reliance on fossil fuels, nations are increasing their adoption of sustainable energy, leading to a boom in the renewable energy industry. Various renewable energy applications, such as solar panels and wind turbines, utilize hydraulic cylinders as an integral component. It is anticipated that the expansion of the renewable energy industry will propel the demand for hydraulic cylinders to unprecedented heights.

Growing Demand In the food and beverage industry

The food and beverage industry is renowned for its adherence to hygiene and safety standards, which necessitates the use of specialized machinery and apparatus. In numerous food and beverage applications, such as labeling machines, filling, and packaging, hydraulic cylinders are utilized. Due to their indispensable nature, the demand for hydraulic cylinders is expected to increase significantly as the industry continues to grow.

Latest Trends

Meeting Specific Client Needs

Due to their ability to meet the specific needs of individual customers, demand for customized hydraulic cylinders has increased in many industries, including construction, agriculture, and mining. These cylinders are tailored to the precise requirements of customers, resulting in decreased downtime, enhanced efficiency, and increased output. To meet the rising demand for customized hydraulic cylinders, manufacturers are implementing innovative technologies that expedite the production process and increase output.

Enhancing Performance and Minimizing Maintenance Costs

Smart hydraulic cylinders equipped with sensors that provide real-time data on variables such as temperature, pressure, and stroke are gaining popularity in industries due to their ability to optimize cylinder performance and decrease outages. The increased adoption of these cylinders is a result of their ability to reduce maintenance costs and enhance overall operational efficacy. To meet the growing demand, manufacturers are investing in research and development to introduce advanced technologies that can further enhance the efficacy of these cylinders.

Reducing Carbon Emissions and Energy Consumption

As the cost of energy continues to rise and environmental concerns increase, industries are placing a greater emphasis on energy-efficient hydraulic systems. These systems are intended to reduce energy consumption and carbon emissions, resulting in substantial cost reductions and enhanced sustainability. To meet this expanding demand, manufacturers are introducing energy-efficient hydraulic systems that optimize machine performance while reducing energy consumption. In addition, manufacturers are investing in R&D to introduce innovative technologies that can further enhance system performance.

Predicting Performance and Increasing Productivity

Popularity has increased for hydraulic cylinder simulation software due to its capacity to simulate cylinder behavior and predict performance under various conditions. Using this software, manufacturers can optimize cylinder design and increase efficiency while reducing costs. As the demand for hydraulic cylinder simulation software increases, manufacturers are investing in R&D to create advanced software that accurately simulates cylinder behavior and predicts performance. With the expanding prevalence of hydraulic cylinder simulation software, manufacturers can enhance the design and performance of cylinders to meet the rising demand for these goods.

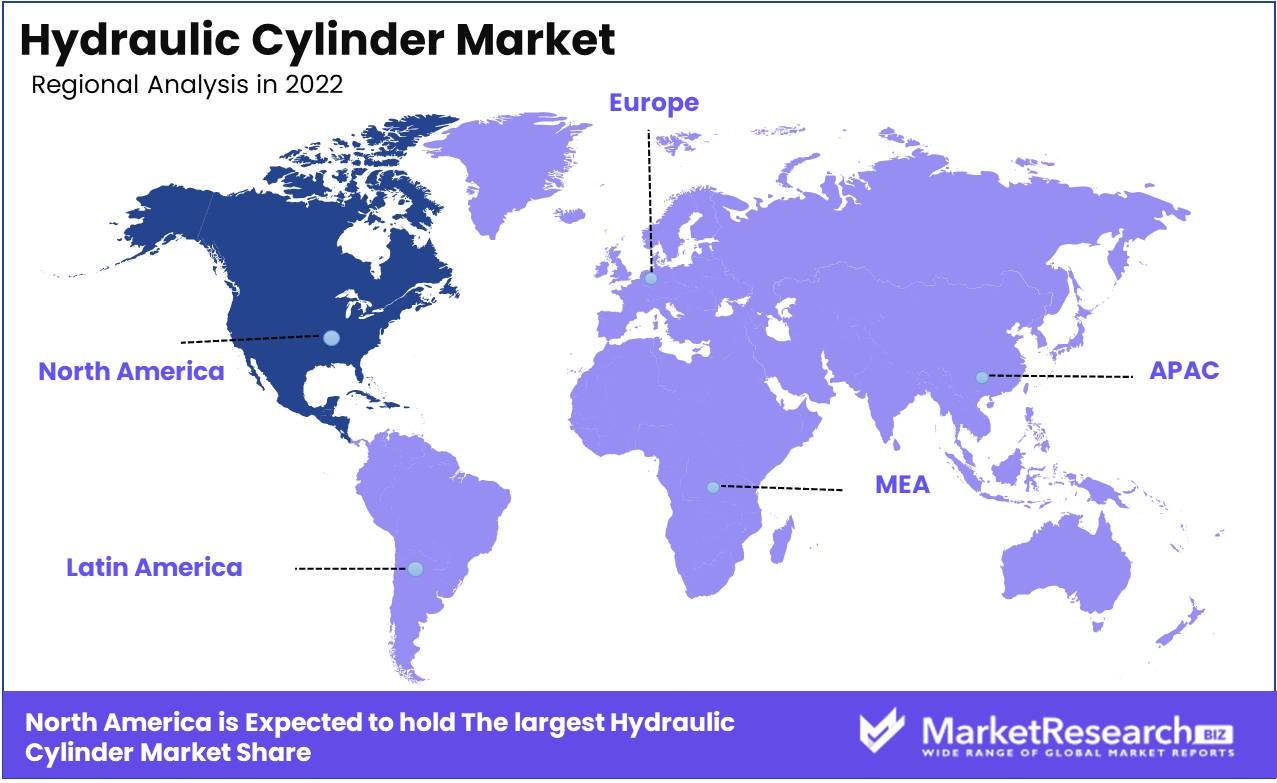

Regional Analysis

North America is home to some of the world's leading hydraulic cylinder manufacturers, serving diverse end-use industries including construction, agricultural equipment, mining, and oil & gas. In response to the increasing demand for hydraulic cylinders, these manufacturers are continually innovating to satisfy their clients' requirements. One of the most essential components of a hydraulic system is the hydraulic cylinder. They transform hydraulic energy into mechanical force, allowing heavy-duty machinery to perform their duties with ease. The effectiveness of hydraulic cylinders is contingent on a number of factors, including the manufacturing process, the quality of the materials employed, and the design.

The presence of significant hydraulic cylinder manufacturers in North America has aided in meeting the rising demand for these components. These manufacturers have consistently pushed the limits of hydraulic technology to provide innovative solutions for a variety of industries. They prioritize delivering unmatched quality and service to their consumers, paving the way for long-term expansion. The region's favorable economic climate is one of the main factors for the significant growth of hydraulic cylinder manufacturers in North America. With the expansion of the industrial sector, the demand for robust and dependable apparatus has increased, which in turn increases the demand for hydraulic cylinders. The availability of competent labor and advanced manufacturing technologies, in addition to the region's government policies, have allowed hydraulic cylinder manufacturers to flourish.

North American hydraulic cylinder manufacturers have also emphasized sustainability. They have been instituting environmentally favorable manufacturing processes, thereby reducing their carbon footprint and conserving natural resources. In addition, they have been developing energy-efficient hydraulic cylinders, resulting in substantial cost reductions for their customers.

Key Regions and Countries

North America

- US

- Canada

- Mexico

Western Europe

- Germany

- France

- The UK

- Spain

- Italy

- Portugal

- Ireland

- Austria

- Switzerland

- Benelux

- Nordic

- Rest of Western Europe

Eastern Europe

- Russia

- Poland

- The Czech Republic

- Greece

- Rest of Eastern Europe

APAC

- China

- Japan

- South Korea

- India

- Australia & New Zealand

- Indonesia

- Malaysia

- Philippines

- Singapore

- Thailand

- Vietnam

- Rest of APAC

Latin America

- Brazil

- Colombia

- Chile

- Argentina

- Costa Rica

- Rest of Latin America

Middle East & Africa

- Algeria

- Egypt

- Israel

- Kuwait

- Nigeria

- Saudi Arabia

- South Africa

- Turkey

- United Arab Emirates

- Rest of MEA

Key Players Analysis

Hydraulic Cylinders Market is a fiercely competitive industry dominated by a multiplicity of key players who exert a significant influence on the market through their cutting-edge technological advancements, innovative product development, and extensive global presence. Bosch Rexroth, Eaton Corporation, Parker Hannifin Corporation, SMC Corporation, and Actuant Corporation are among the main competitors in this dynamic marketplace.

Bosch Rexroth is a leader in the hydraulic cylinder market, renowned for its extensive selection of cylinders, hydraulic controls and systems, and power units that serve a variety of industries, such as mobile equipment, machine tools, and civil engineering. The complexity and versatility of the company's hydraulic cylinders exemplify its unwavering dedication to providing inventive solutions to meet its customers' ever-changing requirements.

Eaton Corporation, an additional formidable participant in the hydraulic cylinder market, possesses an impressive portfolio of hydraulic cylinders that are utilized extensively in the industrial, agricultural, and construction industries. Eaton's hydraulic cylinders are engineered to provide optimal performance, efficiency, and durability in even the most extreme environments.

Parker Hannifin Corporation is a global leader in motion and control technologies, providing a vast array of hydraulic systems, components, and solutions to a variety of industries, such as the aerospace, industrial, and mobile sectors. The range of hydraulic cylinders manufactured by Parker Hannifin, which are renowned for their dependability, precision, and superior quality, exemplifies the company's dedication to constant innovation and ingenuity.

SMC Corporation, a world-renowned pneumatic and industrial automation company, offers an extensive selection of hydraulic cylinders, including compact cylinders, standard cylinders, and precision cylinders, that are designed to meet the diversified requirements of a number of industries. The company's hydraulic cylinders are designed to deliver the highest levels of efficiency, dependability, and performance, making them a top choice for businesses worldwide.

Actuant Corporation, an additional significant actor in the hydraulic cylinder market, provides hydraulic and pneumatic systems and components for a wide range of industries, including oil and gas, power generation, and mining. Actuant Corporation's hydraulic cylinders are designed to deliver unrivaled precision, reliability, and performance, establishing it as an industry powerhouse.

Top Key Players in Hydraulic Cylinder Market

- Bosch Rexroth

- Jiangsu Hengli Hydraulic

- Jarp Industries

- Pacoma

- Parker Hannifin

- Kawasaki Heavy

- Caterpillar

- Actuant Corporation

- Wipro Enterprises

- Texas Hydraulics

- HYDAC

- Eaton Corporation

- SMC Corporation

- Best Metal Products

- WEBER-HYDRAULIK

- Liebherr Group.

Recent Development

In 2021, Parker Hannifin Corporation will introduce a new series of compact hydraulic cylinders with high performance in a small packaging.

In 2020, Bosch Rexroth AG introduced a new line of hydraulic cylinders intended for use in severe environments, including offshore and marine applications.

In 2019, Eaton Corporation plc announced the acquisition of a prominent Turkish manufacturer of hydraulic and electrical equipment, Ulusoy Elektrik Imalat Taahhut ve Ticaret A.S.

In 2018, Caterpillar Inc. introduced its new Cat 320 and 323 excavators, which feature advanced hydraulic systems and enhanced fuel economy.

In 2017, Wipro Infrastructure Engineering (WIN) acquired the Singaporean manufacturer of hydraulic cylinders and precision components H.E Precision Tooling Pte Ltd.

In 2016, An effort to reinforce its position on the European market, Hyva Group acquired Ferrari FVE, a prominent manufacturer of hydraulic cylinders for commercial vehicles.

Report Scope

Report Features Description Market Value (2022) USD 14.88 Bn Forecast Revenue (2032) USD 22.02 Bn CAGR (2023-2032) 4.0% Base Year for Estimation 2022 Historic Period 2016-2022 Forecast Period 2023-2032 Report Coverage Revenue Forecast, Market Dynamics, COVID-19 Impact, Competitive Landscape, Recent Developments Segments Covered Application: Industrial Equipment, Mobile Equipment

End User: Aerospace and Defense, Oil and Gas, Agriculture, Material Handling, Automotive, Construction, Mining, Marine, Others

Product: Tie-Rod Cylinders, Welded Cylinders, Telescopic Cylinders, Mill Type Cylinders, Threaded Cylinders

Functionality: Single Acting Cylinders, Double Acting Cylinders, Multi-Stage/Tandem

Bore Size: Less Than 50 mm, 51 mm to 100 mm, 101 mm to 150 mm, Greater Than 151 mmRegional Analysis North America – The US, Canada, & Mexico; Western Europe – Germany, France, The UK, Spain, Italy, Portugal, Ireland, Austria, Switzerland, Benelux, Nordic, & Rest of Western Europe; Eastern Europe – Russia, Poland, The Czech Republic, Greece, & Rest of Eastern Europe; APAC – China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Malaysia, Philippines, Singapore, Thailand, Vietnam, & Rest of APAC; Latin America – Brazil, Colombia, Chile, Argentina, Costa Rica, & Rest of Latin America; Middle East & Africa – Algeria, Egypt, Israel, Kuwait, Nigeria, Saudi Arabia, South Africa, Turkey, United Arab Emirates, & Rest of MEA Competitive Landscape Bosch Rexroth, Jiangsu Hengli Hydraulic, Jarp Industries, Pacoma, Parker Hannifin, Kawasaki Heavy, Caterpillar, Actuant Corporation, Wipro Enterprises, Texas Hydraulics, HYDAC, Eaton Corporation, SMC Corporation, Best Metal Products, WEBER-HYDRAULIK, Liebherr Group. Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) -

-

- Bosch Rexroth

- Jiangsu Hengli Hydraulic

- Jarp Industries

- Pacoma

- Parker Hannifin

- Kawasaki Heavy

- Caterpillar

- Actuant Corporation

- Wipro Enterprises

- Texas Hydraulics

- HYDAC

- Eaton Corporation

- SMC Corporation

- Best Metal Products

- WEBER-HYDRAULIK

- Liebherr Group.