Gas Cylinder Market By Product (Steel Cylinders, Composite Cylinders, Others), By Wrap Type (HDPE, Glass Fiber, Aramid Fiber, Carbon Fiber, Wrap less), By Gas Type (Inert Gases, Flammable Gases, Toxic Gases, Oxidizers, Pyrophoric Gases), By Application (Kitchen and Domestic, Processing Industries, Medical, Transportation), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 2024-2033

-

37882

-

Aug 2024

-

185

-

-

This report was compiled by Shreyas Rokade Shreyas Rokade is a seasoned Research Analyst with CMFE, bringing extensive expertise in market research and consulting, with a strong background in Chemical Engineering. Correspondence Team Lead-CMFE Linkedin | Detailed Market research Methodology Our methodology involves a mix of primary research, including interviews with leading mental health experts, and secondary research from reputable medical journals and databases. View Detailed Methodology Page

-

Quick Navigation

Report Overview

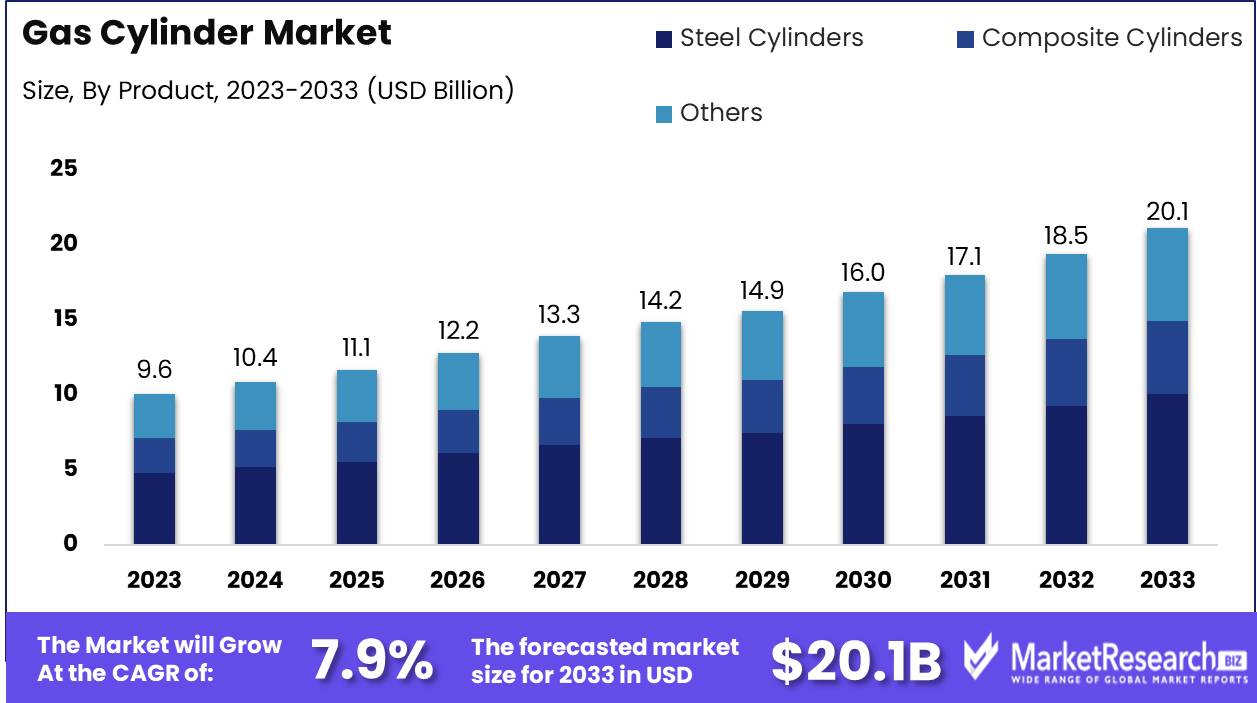

The Global Gas Cylinder Market was valued at USD 9.6 Bn in 2023. It is expected to reach USD 20.1 Bn by 2033, with a CAGR of 7.9% during the forecast period from 2024 to 2033.

The surge in demand in various sectors such as the healthcare industry and the rise in the usage of combustion engines in vehicles are some of the main driving factors in the growth of the gas cylinders market. Gas cylinders are frequently used in the healthcare industry for therapeutic and diagnosis Medical Purposes. Medical oxygen gas cylinders are commonly used for homecare purposes and it is used for elderly patients who are unable to move and require a constant oxygen supply.

Medical gas cylinders play an important role in delivering anesthetic gases to patients. Anesthetic gases are preferred to control the unconscious state of health, ensure pain relief, and provide comfort and relaxation at the time of surgery. These gas cylinders offer a ready-to-use distribution of life-saving gases such as oxygen, carbon dioxide, and nitric oxide which helps to stabilize the patients during any kind of emergency. Oxygen and anesthetic gases are used for specific treatments and therapies.

Medical gas cylinders play an important role in delivering anesthetic gases to patients. Anesthetic gases are preferred to control the unconscious state of health, ensure pain relief, and provide comfort and relaxation at the time of surgery. These gas cylinders offer a ready-to-use distribution of life-saving gases such as oxygen, carbon dioxide, and nitric oxide which helps to stabilize the patients during any kind of emergency. Oxygen and anesthetic gases are used for specific treatments and therapies.For example, helium-oxygen combinations known as heliox, are used for the treatment of patients with acute respiratory issues by providing them with improved gas exchange in the lungs. Likewise, oxygen and nitrogen mixtures, which are medical gases, are used in neonatal ventilator care units and medical tubing to offer respiratory support to premature babies. The utilization of Gas Cylinders for some specific treatments ensures the supply of these products will be efficient and smooth concerning the unique requirements of the patient population.

In the vehicle manufacturing industry, an engine tube car is a compartment in which the vehicle fuel is burned to develop the power of the engine to get started. The average engine on a vehicle is 4,6 or 8 engine gas cylinders. Each tube in the vehicle is linked to the crankshaft, which turns the energy generated by the combustion into rotational mobility. These Pressure Vessels represent the Production of Gas Cylinders and are Essential Commodities in modern automotive technology.

Key Takeaways

- Market Value: The Global Gas Cylinder Market was valued at USD 9.6 Bn in 2023. It is expected to reach USD 20.1 Bn by 2033, with a CAGR of 7.9% during the forecast period from 2024 to 2033.

- By Product: Steel Cylinders dominate with 50%, valued for their durability and strength.

- By Wrap Type: Wrap less cylinders make up 40%, preferred for their simplicity and cost-effectiveness.

- By Gas Type: Flammable Gases constitute 35%, essential for various industrial applications.

- By Application: Processing Industries use 30%, highlighting the need for reliable gas storage solutions.

- Regional Dominance: Asia-Pacific holds a 35% market share, driven by industrial growth and increasing gas demand.

- Growth Opportunity: Developing lightweight and composite material cylinders can enhance safety and portability, driving market expansion.

Driving factors

Increasing Demand for Industrial Gases in Various Applications

The growth of the gas cylinder market is significantly driven by the increasing demand for industrial gases across various applications. Industrial gases such as oxygen, nitrogen, hydrogen, and carbon dioxide are essential in numerous industries, including manufacturing, chemical processing, metal fabrication, and food and beverage production. For instance, oxygen is crucial for metal cutting and welding, while nitrogen is used for inerting and purging applications in the chemical and pharmaceutical industries.

This growing demand necessitates the use of gas cylinders for safe storage and transportation, thus driving market expansion. As industries continue to evolve and expand, the requirement for reliable gas storage solutions will further fuel the growth of the gas cylinder market.

Growth in the Healthcare Sector

The healthcare sector's growth is another pivotal factor contributing to the expansion of the gas cylinder market. Medical gases such as oxygen, nitrous oxide, and medical air are vital for various healthcare applications, including respiratory therapy, anesthesia, and patient care in hospitals and clinics. The World Health Organization (WHO) reported a significant increase in the demand for medical oxygen during the pandemic, highlighting the need for efficient gas cylinder solutions to meet this surge.

The aging global population and the increasing prevalence of chronic diseases are driving the demand for medical gases, further boosting the gas cylinder market. The healthcare sector's ongoing expansion and the essential role of medical gases ensure a steady demand for gas cylinders, contributing to sustained market growth.

Rising Adoption of LPG for Domestic Use

The rising adoption of liquefied petroleum gas (LPG) for domestic use is a major driver of the gas cylinder market. LPG is widely used as a clean and efficient fuel for cooking and heating in households around the world. Governments and environmental agencies promote LPG due to its lower emissions compared to traditional fuels like coal and wood. The World LPG Association reported that global LPG consumption for domestic use has been increasing at a steady rate, with significant growth observed in developing regions.

This shift towards cleaner energy sources is driving the demand for LPG cylinders, as they are the primary means of storing and distributing LPG for domestic use. The continued emphasis on environmental sustainability and clean energy solutions will further propel the gas cylinder market.

Restraining Factors

Stringent Safety and Regulatory Standards

One of the significant retraining factors for the gas cylinder market is the stringent safety and regulatory standards. Gas cylinders, due to their high-pressure contents and potential hazards, are subject to rigorous safety regulations and compliance requirements globally. These standards ensure the safe manufacturing, handling, transportation, and storage of gas cylinders to prevent accidents and ensure public safety.

The complexity and cost associated with adhering to these stringent standards can limit market entry for new players and constrain the expansion of existing companies, thus impacting the overall growth of the gas cylinder market.

High Transportation and Storage Costs

High transportation and storage costs present another critical challenge to the growth of the gas cylinder market. Gas cylinders are heavy and bulky, making them expensive to transport and store. The logistics of moving gas cylinders safely, especially over long distances, require specialized vehicles and handling equipment, further adding to the costs. The storage of gas cylinders necessitates secure, well-ventilated facilities to comply with safety regulations, which can be costly to establish and maintain.

These high costs can affect the profitability of gas cylinder providers and may lead to higher prices for end-users, potentially reducing demand. The economic burden of transportation and storage, therefore, acts as a significant restraining factor in the gas cylinder market.'

By Product Analysis

Steel Cylinders held a dominant market position in the By Product segment of the Gas Cylinder Market, capturing more than a 50% share.

In 2023, Steel Cylinders held a dominant market position in the By Product segment of the Gas Cylinder Market, capturing more than a 50% share. Steel cylinders are favored for their durability, reliability, and cost-effectiveness. They are widely used in various applications, including industrial, medical, and domestic settings, due to their ability to withstand high pressures and harsh conditions.

Composite Cylinders are also gaining traction, known for their lightweight and high-strength properties. These cylinders are increasingly used in applications where weight reduction is crucial, such as in portable gas storage and transportation. Although they currently capture a smaller market share compared to steel cylinders, their popularity is growing in sectors that prioritize efficiency and ease of handling.

Others category includes aluminum and specialty gas cylinders, which are used in niche applications requiring specific material properties.

By Wrap Type Analysis

In 2023, Wrap less held a dominant market position in the By Wrap Type segment of the Gas Cylinder Market, capturing more than a 40% share.

In 2023, Wrap less held a dominant market position in the By Wrap Type segment of the Gas Cylinder Market, capturing more than a 40% share. Wrap less gas cylinders are popular due to their simplicity and ease of manufacturing. They are extensively used in various industries where standard gas storage solutions are sufficient. The dominance of wrap less cylinders is attributed to their lower production costs and widespread applicability.

HDPE (High-Density Polyethylene) and Glass Fiber wrapped cylinders are important for applications requiring enhanced strength and durability. These wrap types are often used in situations where the gas cylinders need to be more resistant to environmental factors and mechanical stress.

Aramid Fiber and Carbon Fiber wraps provide superior strength-to-weight ratios, making them ideal for high-pressure and lightweight applications. These advanced materials are typically used in specialized industrial and commercial settings where performance and safety are paramount.

By Gas Type Analysis

Flammable Gases held a dominant market position in the By Gas Type segment of the Gas Cylinder Market, capturing more than a 35% share.

In 2023, Flammable Gases held a dominant market position in the By Gas Type segment of the Gas Cylinder Market, capturing more than a 35% share. The high demand for flammable gases like propane, butane, and acetylene in industrial, commercial, and domestic applications drives this segment's dominance. These gases are essential for heating, cooking, welding, and other processes, making their storage and transportation in gas cylinders critical.

Inert Gases such as nitrogen, helium, and argon are also significant, used in applications like shielding in welding, inerting, and preserving food and other materials.

Toxic Gases and Oxidizers are used in specialized industrial processes and require stringent safety measures for handling and storage.

Pyrophoric Gases are less common but are used in specific high-tech and industrial applications, necessitating specialized storage solutions due to their reactive nature.

By Application Analysis

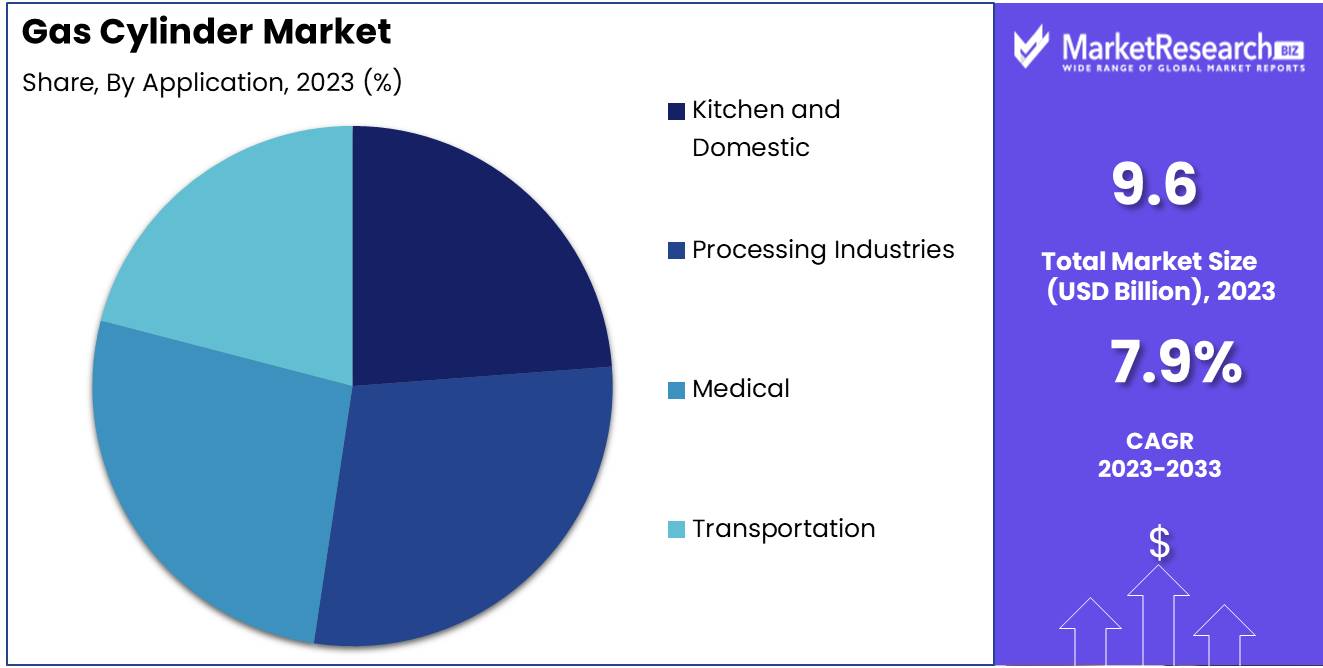

Processing Industries held a dominant market position in the By Application segment of the Gas Cylinder Market, capturing more than a 30% share.

In 2023, Processing Industries held a dominant market position in the By Application segment of the Gas Cylinder Market, capturing more than a 30% share. These industries, including chemical manufacturing, metal processing, and food and beverage production, rely heavily on gas cylinders for various processes. The need for precise and reliable gas delivery systems in these sectors drives the demand for gas cylinders.

Kitchen and Domestic applications also represent a significant portion of the market. Gas cylinders are widely used for cooking and heating in residential settings, particularly in regions where piped gas supply is limited.

Medical applications utilize gas cylinders for storing and delivering medical gases like oxygen, nitrous oxide, and anesthetic gases. The importance of medical gas cylinders has been underscored during health crises, such as the COVID-19 pandemic, where there was a surge in demand for oxygen cylinders.

Transportation sectors use gas cylinders in vehicles powered by compressed natural gas (CNG) and in various other applications requiring portable gas storage solutions. The adoption of environmentally friendly fuel options is expected to further drive demand in this segment.

Key Market Segments

By Product

- Steel Cylinders

- Composite Cylinders

- Others

By Wrap Type

- HDPE

- Glass Fiber

- Aramid Fiber

- Carbon Fiber

- Wrap less

By Gas Type

- Inert Gases

- Flammable Gases

- Toxic Gases

- Oxidizers

- Pyrophoric Gases

By Application

- Kitchen and Domestic

- Processing Industries

- Medical

- Transportation

Growth Opportunity

Development of Lightweight and Durable Composite Cylinders

In 2024, the global gas cylinder market is set to witness significant growth opportunities through the development of lightweight and durable composite cylinders. Traditional steel cylinders, while robust, are heavy and cumbersome, leading to high transportation and handling costs. Composite cylinders, made from advanced materials like carbon fiber, offer a compelling alternative due to their reduced weight and enhanced durability.

These cylinders not only lower transportation and storage costs but also improve safety by being less prone to corrosion and damage. The adoption of these innovative cylinders is likely to increase, driven by their advantages in cost-efficiency and safety, thus propelling the overall gas cylinder market growth.

Expansion in Renewable Energy Applications like Hydrogen Storage

The expansion of renewable energy applications, particularly hydrogen storage, presents another promising opportunity for the gas cylinder market in 2024. As countries globally strive to transition to cleaner energy sources, hydrogen is emerging as a key component of the renewable energy landscape. Hydrogen storage requires advanced gas cylinders capable of withstanding high pressures while ensuring safety and reliability.

Gas cylinders designed for hydrogen storage are essential to support this growth, creating a substantial market opportunity for manufacturers. The shift towards renewable energy and the increasing investment in hydrogen infrastructure are expected to drive the demand for specialized gas cylinders, fostering market expansion.

Latest Trends

Use of Smart Gas Cylinders with Tracking and Monitoring Capabilities

In 2024, the global gas cylinder market is poised to benefit from the trend of smart gas cylinders equipped with tracking and monitoring capabilities. These advanced cylinders utilize IoT technology to provide real-time data on gas levels, pressure, and location, enhancing operational efficiency and safety. Smart cylinders enable proactive maintenance, reduce downtime, and prevent hazardous situations by alerting users to potential issues before they escalate.

This growth reflects the increasing adoption of IoT solutions across various industries, driven by the need for improved asset management and operational transparency. By leveraging smart technology, gas cylinder providers can offer value-added services, such as remote monitoring and automated refills, thereby enhancing customer satisfaction and driving market growth.

Adoption of Eco-Friendly and Recyclable Materials

The adoption of eco-friendly and recyclable materials is another significant trend shaping the gas cylinder market in 2024. As environmental concerns intensify and regulatory pressures mount, there is a growing emphasis on sustainability within the industry. Manufacturers are increasingly using materials such as aluminum and advanced composites that are both durable and recyclable. These materials reduce the environmental impact of gas cylinders by minimizing waste and promoting circular economy practices.

The shift towards sustainable materials not only aligns with global environmental goals but also meets the rising consumer demand for eco-friendly products. This trend is expected to drive innovation and growth in the gas cylinder market, as companies develop greener alternatives to traditional steel cylinders.

Regional Analysis

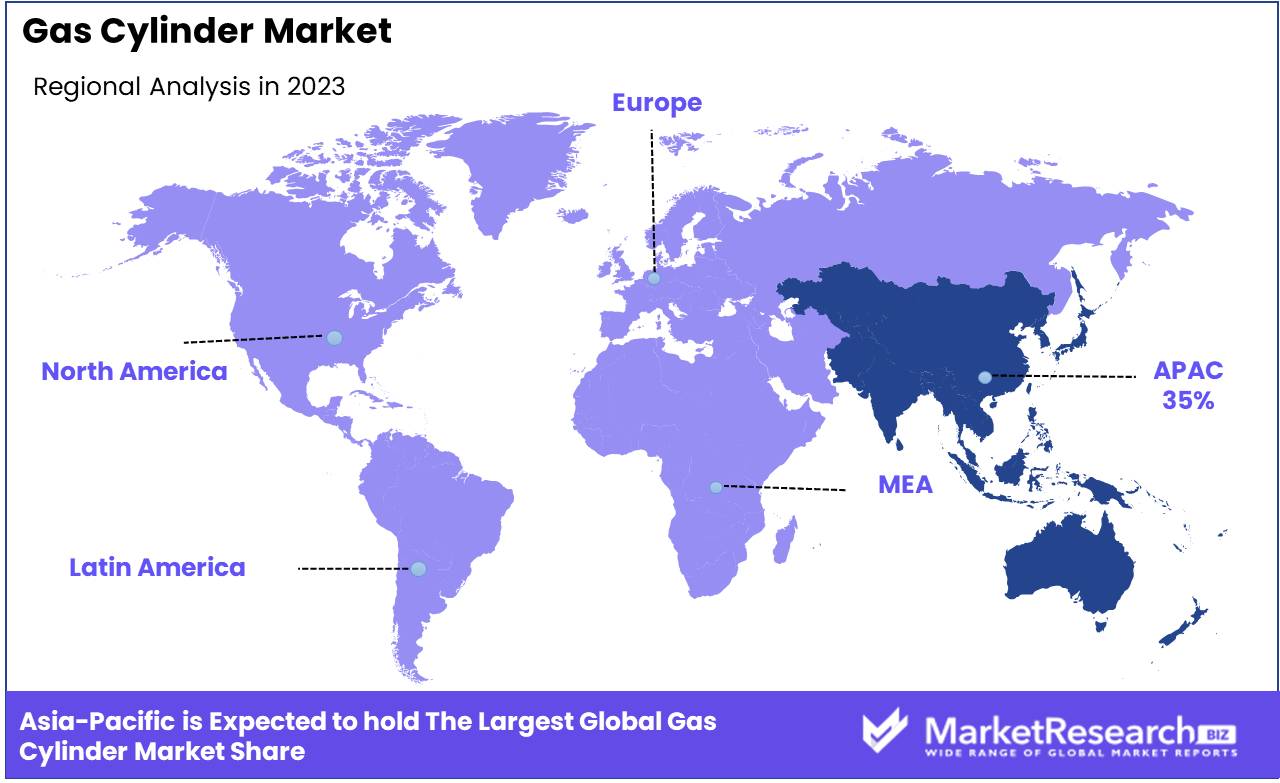

Asia-Pacific dominated the Gas Cylinder Market in 2023, capturing a 35% share.

In 2023, the Asia-Pacific region dominated the Gas Cylinder Market, capturing a 35% share. The rapid industrialization, urbanization, and the growing demand for energy in countries like China, India, and Japan drive the market. The increasing use of gas cylinders in residential, commercial, and industrial applications contributes to market growth. The rise in government initiatives promoting clean energy sources and the expansion of the manufacturing sector further bolster the demand for gas cylinders in the region.

North America is a significant market, with the U.S. and Canada experiencing high demand for gas cylinders across various industries, including healthcare, manufacturing, and energy. The focus on safety standards and technological advancements in gas cylinder manufacturing supports market growth.

Europe follows closely, with countries like Germany, the UK, and France leading in the adoption of gas cylinders. The region benefits from stringent safety regulations and a well-established industrial base that relies heavily on gas cylinders for various applications.

In the Middle East & Africa, the gas cylinder market is emerging, driven by the expanding energy sector and increasing industrial activities. The UAE and Saudi Arabia are notable markets due to their significant investments in energy infrastructure and industrial development.

Latin America is witnessing steady growth, with Brazil and Mexico being key markets. The rising demand for gas cylinders in residential, commercial, and industrial sectors supports the market's development in the region.

Key Regions and Countries

North America

- US

- Canada

- Mexico

Western Europe

- Germany

- France

- The UK

- Spain

- Italy

- Portugal

- Ireland

- Austria

- Switzerland

- Benelux

- Nordic

- Rest of Western Europe

Eastern Europe

- Russia

- Poland

- The Czech Republic

- Greece

- Rest of Eastern Europe

APAC

- China

- Japan

- South Korea

- India

- Australia & New Zealand

- Indonesia

- Malaysia

- Philippines

- Singapore

- Thailand

- Vietnam

- Rest of APAC

Latin America

- Brazil

- Colombia

- Chile

- Argentina

- Costa Rica

- Rest of Latin America

Middle East & Africa

- Algeria

- Egypt

- Israel

- Kuwait

- Nigeria

- Saudi Arabia

- South Africa

- Turkey

- United Arab Emirates

- Rest of MEA

Key Players Analysis

The global gas cylinder market in 2024 is marked by advancements in safety, material innovation, and expanding applications. Luxfer Gas Cylinders and Worthington Industries Inc. lead with their extensive product ranges and focus on lightweight, high-strength materials. Their innovations in composite and aluminum cylinders enhance safety and performance, making them preferred choices across industries.

Hexagon Ragasco AS and FABER INDUSTRIE SPA are notable for their contributions to the automotive sector, particularly in providing cylinders for compressed natural gas (CNG) vehicles. Their expertise in manufacturing high-pressure cylinders supports the growing demand for alternative fuel vehicles. Beijing Tianhai Industry Co., Ltd. and EKC are significant players in the Asian market, offering a wide range of industrial and medical gas cylinders.

Linde plc and Air Liquide dominate with their integrated gas supply solutions, encompassing production, storage, and distribution. Their extensive global networks ensure reliable supply and innovative solutions tailored to various industrial applications. Time Technoplast Ltd. and Drägerwerk AG & Co. KGaA are known for their focus on safety and regulatory compliance, critical factors in the gas cylinder industry.

MS GROUP and Zhejiang Tianlong Cylinder Co., Ltd. cater to regional markets with their cost-effective and reliable products, addressing local demand effectively. Catalina Cylinders and Norris Cylinder Company are prominent in the U.S., providing high-quality cylinders for a range of applications, including healthcare and industrial gases. The gas cylinder market in 2024 is driven by innovation in materials, safety enhancements, and expanding applications across sectors, ensuring steady growth and increased market penetration.

Market Key Players

- 3M

- Aygaz A.Ş.

- FABER INDUSTRIE SPA

- Hexagon Ragasco AS

- Luxfer Gas Cylinders

- Worthington Industries Inc

- Beijing Tianhai Industry Co., Ltd.

- Drägerwerk AG & Co. KGaA

- EKC

- Linde plc

- Time Technoplast Ltd.

- MS GROUP

- Welz Gas Cylinder GmbH

- Zhejiang Tianlong cylinder Co., L.T.D.

- Praxair

- Air Liquide

- Gelest Inc.

- Norris Cylinder Company

- Catalina Cylinders

- MNKgases

- Cyl-Tec

- ECS

- JAI MARUTI GAS

- BOC (Linde)

- Rama Cylinders

- Air Products

- Gas Cylinder Source

- Afrox

- Chart Industries

- Everest Kanto Cylinder Ltd.

Recent Development

- In May 2024, Linde plc invested $30 million in upgrading their production facilities to enhance efficiency and meet growing demand for gas cylinders. This investment aims to improve production capacity by 25%.

- In January 2024, Luxfer Gas Cylinders introduced a new lightweight gas cylinder designed for industrial applications. This cylinder aims to reduce transportation costs by 20%.

Report Scope

Report Features Description Market Value (2023) USD 9.6 Bn Forecast Revenue (2033) USD 20.1 Bn CAGR (2024-2033) 7.9% Base Year for Estimation 2023 Historic Period 2018-2023 Forecast Period 2024-2033 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Product (Steel Cylinders, Composite Cylinders, Others), By Wrap Type (HDPE, Glass Fiber, Aramid Fiber, Carbon Fiber, Wrap less), By Gas Type (Inert Gases, Flammable Gases, Toxic Gases, Oxidizers, Pyrophoric Gases), By Application (Kitchen and Domestic, Processing Industries, Medical, Transportation) Regional Analysis North America - The US, Canada, & Mexico; Western Europe - Germany, France, The UK, Spain, Italy, Portugal, Ireland, Austria, Switzerland, Benelux, Nordic, & Rest of Western Europe; Eastern Europe - Russia, Poland, The Czech Republic, Greece, & Rest of Eastern Europe; APAC - China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Malaysia, Philippines, Singapore, Thailand, Vietnam, & Rest of APAC; Latin America - Brazil, Colombia, Chile, Argentina, Costa Rica, & Rest of Latin America; Middle East & Africa - Algeria, Egypt, Israel, Kuwait, Nigeria, Saudi Arabia, South Africa, Turkey, United Arab Emirates, & Rest of MEA Competitive Landscape 3M, Aygaz A.Ş., FABER INDUSTRIE SPA, Hexagon Ragasco AS, Luxfer Gas Cylinders, Worthington Industries Inc, Beijing Tianhai Industry Co., Ltd., Drägerwerk AG & Co. KGaA, EKC, Linde plc, Time Technoplast Ltd., MS GROUP, Welz Gas Cylinder GmbH, Zhejiang Tianlong cylinder Co., L.T.D., Praxair, Air Liquide, Gelest Inc., Norris Cylinder Company, Catalina Cylinders, MNKgases, Cyl-Tec, ECS, JAI MARUTI GAS, BOC (Linde), Rama Cylinders, Air Products, Gas Cylinder Source, Afrox, Chart Industries, Everest Kanto Cylinder Ltd. Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) -

-

- 3M

- Aygaz A.Ş.

- FABER INDUSTRIE SPA

- Hexagon Ragasco AS

- Luxfer Gas Cylinders

- Worthington Industries Inc

- Beijing Tianhai Industry Co., Ltd.

- Drägerwerk AG & Co. KGaA

- EKC

- Linde plc

- Time Technoplast Ltd.

- MS GROUP

- Welz Gas Cylinder GmbH

- Zhejiang Tianlong cylinder Co., L.T.D.

- Praxair

- Air Liquide

- Gelest Inc.

- Norris Cylinder Company

- Catalina Cylinders

- MNKgases

- Cyl-Tec

- ECS

- JAI MARUTI GAS

- BOC (Linde)

- Rama Cylinders

- Air Products

- Gas Cylinder Source

- Afrox

- Chart Industries

- Everest Kanto Cylinder Ltd.