Wood Plastic Composites Market By Product(Polyethylene wood-plastic composites, Polypropylene wood-plastic composites,and other ), By Application(Building & construction, Automotive, and Other), By Region And Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, And Forecast 2023-2032

-

23156

-

March 2023

-

183

-

-

This report was compiled by Shreyas Rokade Shreyas Rokade is a seasoned Research Analyst with CMFE, bringing extensive expertise in market research and consulting, with a strong background in Chemical Engineering. Correspondence Team Lead-CMFE Linkedin | Detailed Market research Methodology Our methodology involves a mix of primary research, including interviews with leading mental health experts, and secondary research from reputable medical journals and databases. View Detailed Methodology Page

-

Quick Navigation

Report Overview

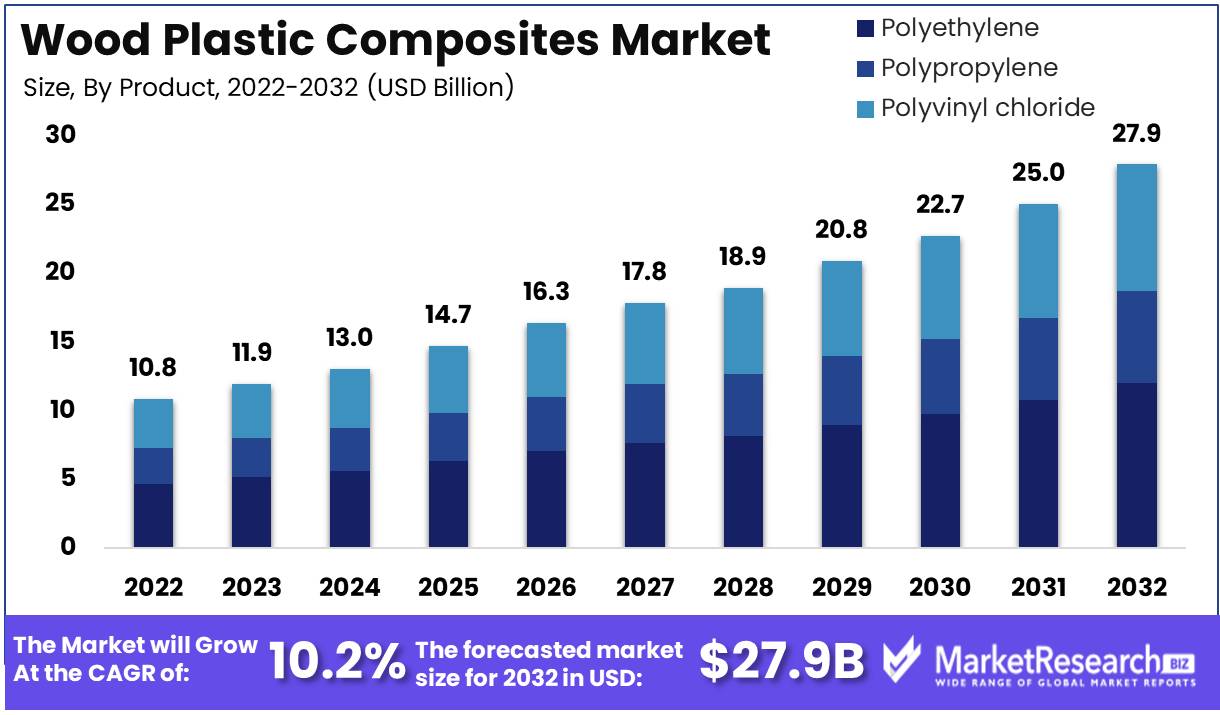

Wood Plastic Composites Market size is expected to be worth around USD 27.9 Bn by 2032 from USD 10.8 Bn in 2022, growing at a CAGR of 10.2% during the forecast period from 2023 to 2032.

wood-plastic composite is a hybrid material that mixes wood with polymers. Due to its outstanding strength and durability, WPC is quickly gaining favor in the construction, automotive, and packaging sectors. WPC products are developed to give the natural beauty of the wood while also providing the flexibility of plastics, so creating a material that is resistant to weather and moisture, making it excellent for use in applications that take place outside.

Wood fibers and polymers are combined in a complicated process during the creation of WPC products, creating a hybrid material that is not only simple to mold and shape but also weather resistant and long-lasting. The utilization of recycled materials, which lowers the environmental effect of creating WPC products, is one of the most significant advances in the WPC market.

Businesses wanting to create new applications and products are investing a substantial amount of money in the WPC market. For instance, IKEA uses WPC materials in some of its furniture products; Ford uses WPC materials in some of its automobile products; and many businesses are using WPC materials in packaging products to create more weather-resistant and long-lasting solutions for customers.

WPC materials are also being utilized to create products that are being printed using 3D technology, which enables businesses to create bespoke forms and patterns. Using WPC to create decking, cladding, and fence products, the construction sector is particularly interested in it. For interior and external components like door panels, dashboards, and bumpers, the car industry is also using WPC materials. In addition, the packaging sector is using WPC materials to create long-lasting and weather-resistant pallets and shipping containers.

Investments are being made in recycled WPC materials and sustainable production techniques as a direct result of the increased demand for environmentally friendly products. Businesses are placing a greater emphasis on openness, accountability, and explainability when it comes to the process of creating WPC products as the market for these products continues to expand. Even while the WPC market has many benefits to provide, there are ethical questions regarding the influence it has on the surrounding environment. These issues are being addressed by the use of sustainable production processes and the utilization of recycled materials.

Driving factors

Demand on the rise for environmentally friendly materials

The necessity for environmentally friendly materials has become of the utmost importance as the number of people concerned about the environment and calling for more sustainable practices has increased. As a result of the increased demand, wood-plastic composites, often known as WPCs, have arisen as a practical alternative to traditionally used materials. These composites are created from recycled materials and can be recycled, making them an environmentally beneficial option. The WPCs market has experienced significant growth as a direct result of the rising demand for environmentally friendly materials.

The Rise in Automotive Industry

The rising usage of these materials in the automobile industry is another key element leading to the growth of the WPCs market. The interiors of vehicles produced by major manufacturers are increasing including WPCs, most notably in the door panels and seat backs. These composites have great features such as high strength, low weight, and durability, making them an excellent option for the automobile sector. These composites are also available in a variety of colors.

The Availability of Raw Materials

Another aspect that has had a beneficial impact on the WPCs market is the ease of availability of both wood fibers and plastic. These composites can be produced in huge quantities at reasonable costs, which has led to a growth in the number of sectors that offer them as an option.

Superior Properties

In addition, as compared to conventional materials such as steel, aluminum, and wood, the qualities of WPCs are significantly more desirable. These composites are resistant to dampness, insect infestation, and mold, making them an option that is more robust and will endure for a longer period of time.

Regulations and Other Regulatory Changes

On the other hand, in the not-too-distant future, the wood plastic composites market might be subject to potential regulatory shifts. For example, stringent restrictions may be introduced to guarantee that the materials used in the production of these composites are both secure and ecologically responsible. If this occurs, the dynamics of the market may be altered.

The Consequences of Newly Emerging Technologies

In the not-too-distant future, emerging technologies like 3D printing and artificial intelligence may potentially have an impact on the WPCs market. These technologies have the potential to expedite the production process and drive down prices, hence making WPCs a more appealing option for manufacturers to consider.

Potential Disruptors

The competitive environment of the WPCs market may be impacted by a number of potential disruptors, such as increasing prices for raw materials and the arrival of new firms. The growth of this market may also be significantly impacted by new tendencies or shifts in the behavior of consumers.

Restraining Factors

Availability of Raw Materials is Limited

The limited availability of raw materials is one of the primary obstacles facing the wood plastic composites market. Wood fibers, plastics, and additives make up the raw materials for WPCs production. The availability of wood fibers is especially limited, as the production process requires defect-free wood fibers with specific moisture content. This shortage of wood fibers can result in higher production costs, which can have a negative impact on market growth.

Insufficient Product Awareness

Limited product awareness is another significant factor restraining the wood plastic composites market. Numerous consumers are unaware of the benefits and possible applications of WPCs. This limited awareness can contribute to a lack of demand for WPCs products, resulting in lower sales volumes and income for manufacturers.

Extremely High Manufacturing Complexity

Manufacturing wood-plastic composites requires specialized equipment and knowledge. The production of WPCs involves various processes, including the treatment of wood fibers, compounding, granulation, and extrusion/molding. This complexity results in high production costs, which increase the price of the ultimate product. The growth of the wood plastic composites market may be constrained by these high prices, which may discourage prospective purchasers.

Dependence on Specific Applications

The wood plastic composites market is predominantly propelled by its application in specific industries, such as the building and construction, automotive, and furniture sectors. Consequently, the industry depends on the growth and demand of these specific industries. Any decrease in the growth of these industries can have a negative impact on the growth of the wood plastic composites market, thereby limiting its potential.

Overcoming These Restraint Factors

Multiple strategies can be implemented to overcome these limiting factors. To address the limited availability of raw materials, manufacturers may, for instance, seek novel and inventive methods to obtain wood fibers. They can also explore the possibility of substituting wood fibers for other materials, such as agricultural refuse. This can help reduce the cost of raw materials, thereby lowering the price of WPCs.

Effective marketing campaigns can be implemented to educate consumers about the benefits of WPCs in order to overcome limited product awareness. In addition to collaborating with architects and construction companies, manufacturers can promote the use of WPCs in commercial and residential construction projects.

To overcome the high complexity of manufacturing, innovation in the production process can aid in cost reduction. The introduction of new technologies that accelerate the production process and reduce waste can also help reduce production costs.

Covid-19 Impact on Wood-Plastic Composites Market

The COVID-19 pandemic has led to a substantial impact on the wood plastic composites market (WPC). The global economy has suffered, and the WPC market has not been immune. The deterioration in the industry has impacted the production, sales, and supply of WPC products.

The pandemic has led to the cessation of manufacturing units and supply channels, which has affected the production and supply of WPC products. The global implementation of security measures has resulted in a shortage of basic materials required for the production of WPC products. The disruption in the supply chain has resulted in delayed shipments of WPC products, leading to a decline in sales.

After the lifting of lockdown measures, manufacturing units are progressively reopening and the market is gradually recuperating. The resumption of production and supply of raw materials has led to an increase in the supply of WPC products, thereby restoring market equilibrium.

Additionally, the pandemic has affected the sales of WPC products. Reduced consumer expenditure has resulted from the global economic downturn, leading to a decline in demand for WPC products. The pandemic has also led to the cancellation or postponement of construction projects, leading to a decrease in demand for WPC decking and other outdoor products.

However, the demand for WPC products is expected to increase as people begin to spend more time outdoors as a result of the pandemic's restrictions. The growing interest in outdoor living spaces makes WPC products an excellent choice for outdoor use due to their durability and weather resistance.

The COVID-19 pandemic has also led to a shift in consumer behavior. Consumers are becoming increasingly conscious of the significance of eco-friendliness and sustainability. This has led to an increase in demand for eco-friendly products, such as WPC products. Due to their eco-friendliness and sustainability, consumers are choosing WPC products over traditional wood products.

The WPC market is expected to expand in the coming years as a result of the shift in consumer behavior. As more consumers become aware of the benefits of eco-friendly and sustainable products, the demand for WPC products is expected to increase.

Product Analysis

The wood plastic composite market is dominated by the polyethylene segment, which contributes to its robust growth. Polyethylene is a thermoplastic polymer with a high density that is widely employed in the manufacture of packaging materials. Due to its low melting point and pliability, polyethylene is also extensively employed in the manufacture of plastic bags and bottles.

In recent years, the Wood Plastic Composites market has exploded due to the enormous economic growth in emerging economies. The emergence of these countries as major economic powers has driven the demand for novel materials to be used as building materials, with WPC being one of the most widely adopted materials. The demand for WPC materials has been driven by the accelerated growth of the construction industry in these countries.

The need for eco-friendly, long-lasting, and low-maintenance materials has driven up the demand for WPC materials at an alarming rate. Due to its exceptional mechanical properties, such as high strength, durability, and resistance to moisture and heat, polyethylene is a popular choice for WPC materials. Consumers seek products that are reasonably priced, durable, and low-maintenance. Due to its superior quality and durability, the polyethylene segment has dominated the WPC market.

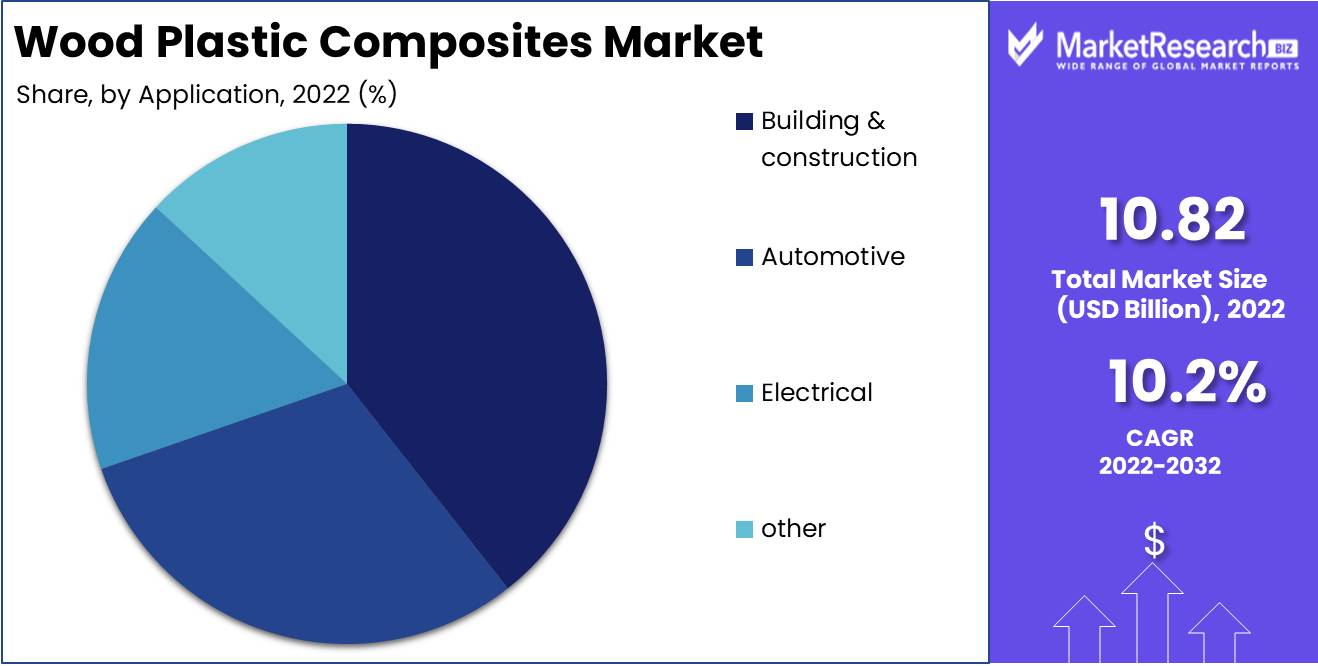

Application area analysis

The main application areas for WPC products are the building and construction industries, with the building and construction sector contributing the largest proportion to the overall WPC market. Given the increasing demand from consumers and the rapid expansion of the global construction industry, it is anticipated that this market segment will continue to dominate the market in the coming years. This dominance is attributable to its eco-friendly, durable, and affordable properties.

In recent decades, emerging economies such as China, India, Brazil, and Russia have experienced tremendous economic growth, resulting in a substantial demand for new construction. The demand for new materials, such as Wood Plastic Composites, is rising as a result of the growth of the construction industry in these countries. The low cost, durability, and convenience of installation of these materials have made them a popular option for construction in emerging economies.

The increased demand for eco-friendly products has stimulated the construction industry's interest in WPC materials. Consumers desire high-quality products that not only meet their needs but also contain eco-friendly and sustainable materials. In response, the building and construction segment has increased its demand for WPC materials, which offer durability and affordability.

Key Market Segments

By Product

- Polyethylene wood-plastic composites

- Polypropylene wood-plastic composites

- Polyvinyl chloride wood-plastic composites

By Application

- Building & construction

- Automotive

- Electrical

- Toys, Trays, Musical Instruments, and Shoe Soles.

Growth Opportunity

Escalating Demand For Eco-Friendly and Sustainable Building Materials

As people become more aware of the long-term environmental impact of traditional building materials, there is a growing demand for sustainable and environmentally friendly building materials. Wood Plastic Composites provide a sustainable alternative to traditional materials like wood, which is frequently exploited in an unsustainable manner.

WPC is produced from recycled plastic and wood waste materials, making it an eco-friendly option for architects and builders. In addition, the production of WPC requires less energy and generates fewer emissions than traditional materials, making it an attractive option for consumers who are concerned about the environment.

Demand for low-maintenance building materials is increasing

Low-maintenance building materials are becoming increasingly popular, particularly in the commercial sector. WPC requires minimal maintenance because it is resistant to moisture and decay, which are typical issues with traditional building materials.

WPC does not require painting or staining, reducing the quantity of long-term maintenance required. The low-maintenance nature of WPC makes it an attractive material for commercial construction, as it reduces maintenance expenses and improves return on investment.

Increasing Demand in the Packaging Business

The expansion of the packaging industry presents an opportunity for the WPC market to expand. As a sustainable alternative to traditional materials such as paper and cardboard, WPC is becoming increasingly popular in the packaging industry.

WPC can be used to create lightweight and durable packaging materials for a variety of products, including food and pharmaceuticals. Compared to traditional materials, the use of WPC in the packaging industry contributes to a reduction in waste and environmental impact.

Greater Emphasis on Product Innovation

The WPC market is experiencing a growing emphasis on product innovation, with manufacturers developing new and enhanced products that offer greater advantages than traditional materials. This has led to an increase in the use of WPC in industries such as automotive and furniture, in addition to construction and packaging.

With technological advancements and a growing emphasis on sustainability, we can anticipate more innovative products on the WPC market in the future. This market is just beginning to realize its growth potential, and there are ample opportunities for new entrants to enter and capitalize on the rising demand.

Latest Trends

Demand for eco-friendly materials is increasing

The demand for wood-plastic composites has been consistently rising as the world becomes more aware of the urgent need for sustainable and eco-friendly solutions. As a consequence, manufacturers in the industry are concentrating on developing environmentally sustainable and cost-effective new products.

As their name suggests, wood-plastic composites consist of wood fiber, plastic, and other additives such as stabilizers and pigments. This composite material is an eco-friendly substitute for conventional materials such as wood, steel, and concrete. These composites are durable and resistant to moisture, insects, and degradation, making them a great option for outdoor applications.

Increasing Construction Work

The increased construction activity around the world is another significant factor driving the expanding Wood Plastic Composites market. As the demand for affordable and sustainable housing, as well as infrastructure development initiatives, has increased, so has the demand for innovative building materials.

Composites made of wood and plastic have found widespread use in the construction industry due to their superior strength, adaptability, and affordability. These composites are used to manufacture, among other things, decking, fencing, cladding, roofing, and window casings.

Growing Demand for Outdoor Furniture

In recent years, outdoor living has become increasingly popular, and this trend has substantially increased the demand for wooden furniture. Traditional wooden furniture, however, is susceptible to weather-related harm such as rot, fracturing, and warping. Composites made of wood and plastic are now available. These composites are exceptionally resistant to environmental factors such as moisture, heat, and UV rays, making them an ideal material for outdoor furniture.

As the market for sustainable and eco-friendly furniture expands, so does the demand for wood-plastic composites. In addition to providing a durable and long-lasting solution, the use of these composites in outdoor furniture promotes sustainable and eco-friendly practices.

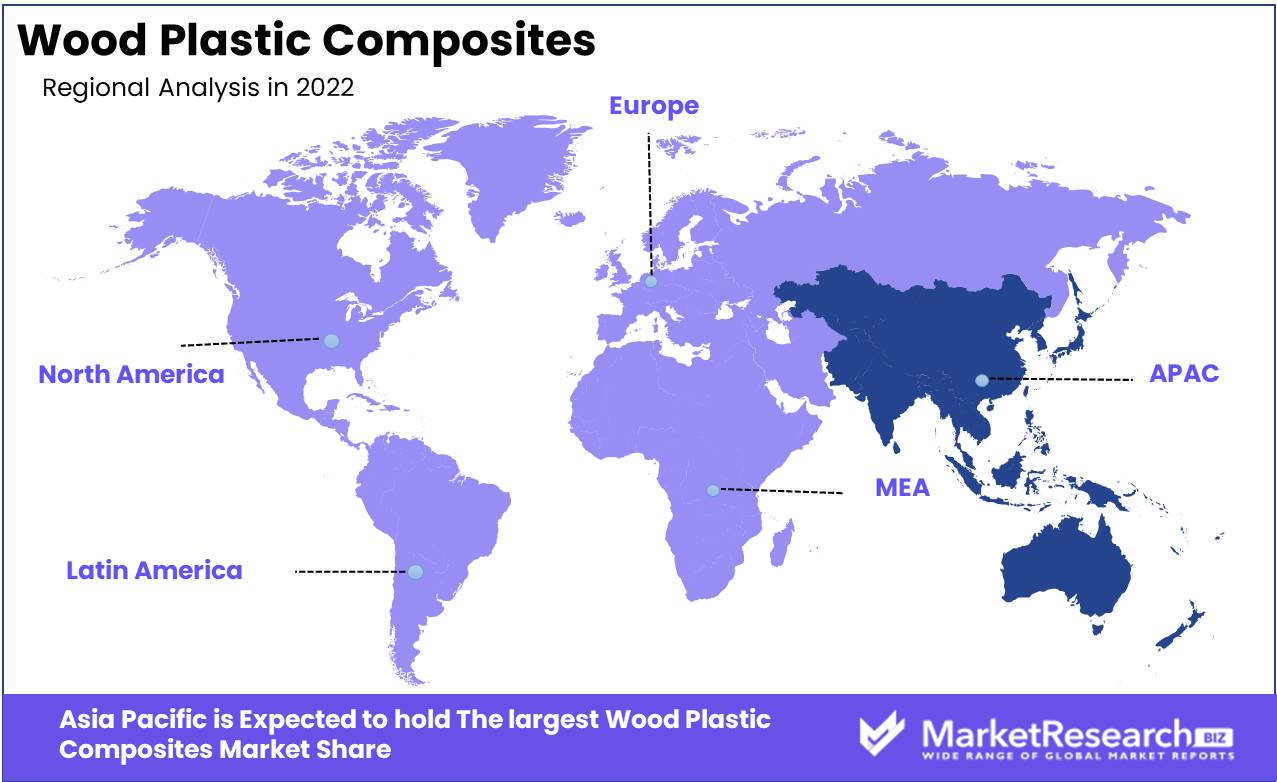

Regional Analysis

By 2032, Asia Pacific Will Hold 30.11 percent of the Global Wood Plastic Composites Market.

Asia Pacific is anticipated to hold a 30.11 percent share of the global wood plastic composites market by the end of 2032. This increase is attributable to the growing demand for eco-friendly and sustainable materials in various application sectors, such as construction, automotive, and consumer goods.

Wood-plastic composites are manufactured by combining wood fibers, such as sawdust and bamboo, with thermoplastic polymers, such as polyethylene, polypropylene, and polyvinyl chloride. In recent years, these materials have acquired considerable popularity due to their superior mechanical properties, durability, and low maintenance requirements.

Due to the growing construction industry in emerging economies such as China and India, the demand for wood-plastic composites in the Asia Pacific region is expected to soar in the future years. As a result of accelerated urbanization and rising disposable incomes, there is an increased demand for new housing, leading to an increase in demand for construction materials, including wood-plastic composites.

The Asia Pacific automotive industry presents significant growth opportunities for the wood plastic composites market. In automotive applications, the demand for wood-plastic composites is expected to be driven by the increasing demand for lightweight materials to increase fuel efficiency and reduce carbon emissions. As wood-plastic composites offer superb insulating properties, the increasing emphasis on electric vehicles in the region also presents a growth opportunity for the market.

Consumer goods, such as furniture and decking, are expected to contribute considerably to the growth of the wood plastic composites market in the Asia Pacific. Growing consumer awareness of eco-friendly and sustainable products is leading to an increase in demand for wood plastic composites in these applications.

Key Regions and Countries

North America

- US

- Canada

- Mexico

Western Europe

- Germany

- France

- The UK

- Spain

- Italy

- Portugal

- Ireland

- Austria

- Switzerland

- Benelux

- Nordic

- Rest of Western Europe

Eastern Europe

- Russia

- Poland

- The Czech Republic

- Greece

- Rest of Eastern Europe

APAC

- China

- Japan

- South Korea

- India

- Australia & New Zealand

- Indonesia

- Malaysia

- Philippines

- Singapore

- Thailand

- Vietnam

- Rest of APAC

Latin America

- Brazil

- Colombia

- Chile

- Argentina

- Costa Rica

- Rest of Latin America

Middle East & Africa

- Algeria

- Egypt

- Israel

- Kuwait

- Nigeria

- Saudi Arabia

- South Africa

- Turkey

- United Arab Emirates

- Rest of MEA

CertainTeed is a prominent manufacturer of construction materials in North America, including wood-plastic composite (WPC) decking. The company's WPC decking products are known for their resilience, low maintenance needs, and resistance to discoloration, staining, and mildew growth. CertainTeed's WPC decking products are made from a combination of recycled wood fibers and recycled plastic, making them an eco-friendly choice.

Fiberon is a well-known producer of composite decking and balustrade products, as well as WPC decking. The company's WPC decking products are made from a combination of recycled wood fibers and recycled plastic and are known for their durability, minimal maintenance needs, and resistance to fading, staining, and mildew development. Fiberon's WPC decking products are available in a range of colors and designs, making them a popular choice among homeowners and contractors.

TimberTech is an industry leader in the production of composite decking and balustrade products, including WPC decking. The company's WPC decking products are known for their durability, minimal maintenance needs, and resistance to fading, staining, and mold growth because they are made from a blend of recycled wood fibers and recycled plastic. TimberTech's WPC decking products are available in a wide range of colors and textures, making them a popular option among homeowners and contractors.

AERT is a prominent producer of WPC decking and balustrade products under the brand name "MoistureShield." The company's WPC decking products are made from a blend of recycled wood fibers and plastic and are known for their durability, minimal maintenance requirements, and resistance to fading, staining, and mold development. MoistureShield decking products from AERT are available in a wide range of colors and designs, making them a popular option for both homeowners and contractors.

Trex Company is the largest producer of WPC decking in the United States and is well-known for its high-quality composite decking products. Trex decking products are known for their durability, minimal maintenance needs, and resistance to fading, staining, and mold growth. They are made from a blend of recycled wood fibers and plastic. Trex's WPC decking products are available in a range of colors and designs, making them a popular choice for contractors and homeowners.

Top Key Players in Wood-Plastic Composites Market

- Trex Company Inc.

- TimberTech Limited

- WPC-Wood Plastic A.S.

- Fiberon LLC.

- Perth Wood Plastic Composite Co Ltd.

- Advanced Environmental Recycling Technologies (AERT)

- Solvay S.A.

- Beologic N.V.

- CertaiTeed Corporation

- Louisiana Pacific Corporation

- Strandex Corporation

- JELU-WERK J. Ehrler GmbH & Co. KG

Recent Development

In February 2021 A significant development in the wood plastic composites market was recently disclosed by Teknor Apex Co., one of the top plastic compounding businesses. The business unveiled a highly weather-resistant complex made especially for material decks' exterior coatings.

Customers will benefit from this ground-breaking new product's unsurpassed durability and protection for their decking materials, which is expected to change the industry. The new complex was built using cutting-edge technology and is intended to endure the worst weather conditions, such as constant UV exposure, dampness, and severe temperatures.

The wood plastic composites market is anticipated to expand steadily in the next years due to the rising need for durable and sustainable decking solutions. The introduction of this cutting-edge new product from Teknor Apex Co. is expected to significantly contribute to this expansion and provide customers with premium, long-lasting decking materials.

The company's new complex has already drawn a lot of attention and has been positioned as a game-changer for the industry. It promises to have higher durability and performance while also having a smaller environmental effect.

Teknor Apex Co., a market leader in plastic compounding, is well-positioned to benefit from the rising demand for premium decking materials. This most recent advancement is consistent with the company's track record of creating creative and sustainable solutions.

The new weatherable complex from Teknor Apex Co. is expected to become the industry standard for durable plastic composites in the decking market.

Report Scope:

Report Features Description Market Value (2022) USD 10.8 Bn Forecast Revenue (2032) USD 27.9 Bn CAGR (2023-2032) 10.2% Base Year for Estimation 2022 Historic Period 2016-2022 Forecast Period 2023-2032 Report Coverage Revenue Forecast, Market Dynamics, COVID-19 Impact, Competitive Landscape, Recent Developments Segments Covered By Product(Polyethylene wood-plastic composites, Polypropylene wood-plastic composites, Polyvinyl chloride wood-plastic composites), By Application(Building & construction, Automotive, Electrical, Toys, Trays, Musical Instruments, and Shoe Soles) Regional Analysis North America – The US, Canada, & Mexico; Western Europe – Germany, France, The UK, Spain, Italy, Portugal, Ireland, Austria, Switzerland, Benelux, Nordic, & Rest of Western Europe; Eastern Europe – Russia, Poland, The Czech Republic, Greece, & Rest of Eastern Europe; APAC – China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Malaysia, Philippines, Singapore, Thailand, Vietnam, & Rest of APAC; Latin America – Brazil, Colombia, Chile, Argentina, Costa Rica, & Rest of Latin America; Middle East & Africa – Algeria, Egypt, Israel, Kuwait, Nigeria, Saudi Arabia, South Africa, Turkey, United Arab Emirates, & Rest of MEA Competitive Landscape Trex Company Inc., TimberTech Limited, WPC-Wood Plastic A.S., Fiberon LLC., Perth Wood Plastic Composite Co Ltd., Advanced Environmental Recycling Technologies (AERT), Solvay S.A., Beologic N.V., CertaiTeed Corporation, Louisiana Pacific Corporation, Strandex Corporation, JELU-WERK J. Ehrler GmbH & Co. KG Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) -

-

- Trex Company Inc.

- TimberTech Limited

- WPC-Wood Plastic A.S.

- Fiberon LLC.

- Perth Wood Plastic Composite Co Ltd.

- Advanced Environmental Recycling Technologies (AERT)

- Solvay S.A.

- Beologic N.V.

- CertaiTeed Corporation

- Louisiana Pacific Corporation

- Strandex Corporation

- JELU-WERK J. Ehrler GmbH & Co. KG