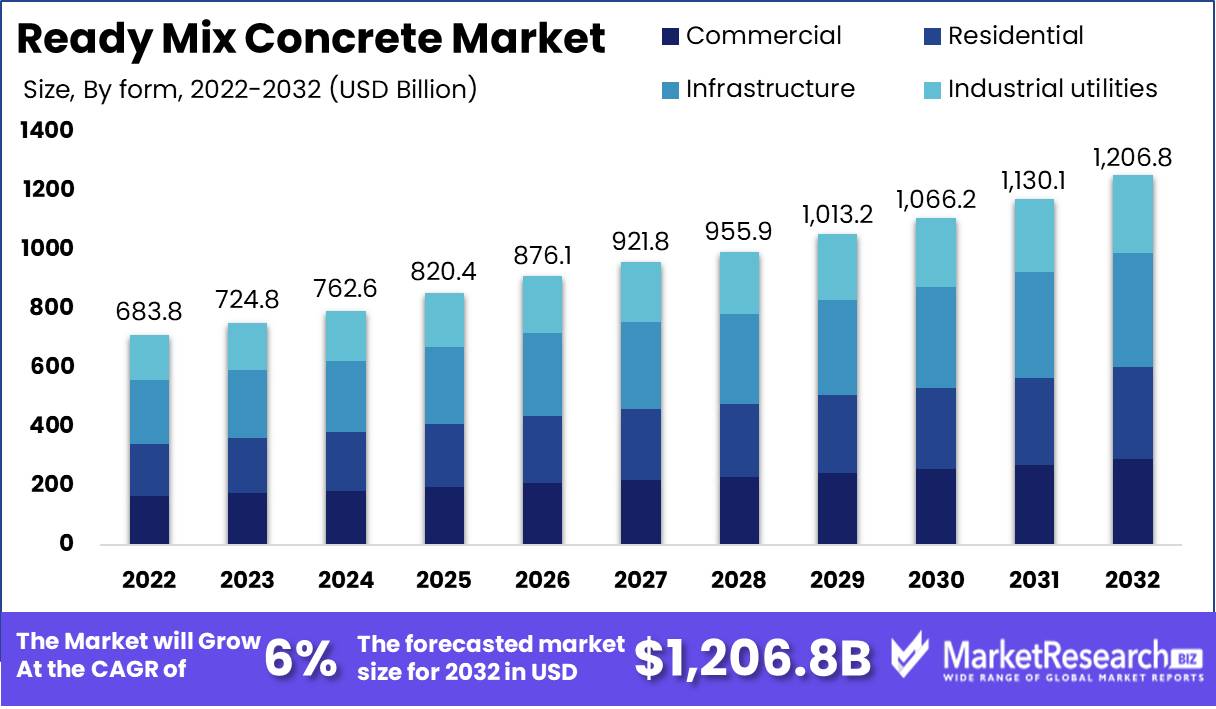

Ready Mix Concrete Market By Application(Commercial, Residential, Infrastructure, Industrial utilities), By Product Type(Transit Mix Concrete, Central Mix Concrete, Shrink Mix Concrete), By Delivery Model(Onsite, Offsite), By Region And Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, And Forecast 2023-2032

This report was compiled by Correspondence Linkedin | Detailed Market research Methodology Our methodology involves a mix of primary research, including interviews with leading mental health experts, and secondary research from reputable medical journals and databases. View Detailed Methodology Page

-

Report Overview

Ready Mix Concrete Market size is expected to be worth around USD 1206.8 Bn by 2032 from USD 683.8 Bn in 2022, growing at a CAGR of 6% during the forecast period from 2023 to 2032.

Over the years, the ready mix concrete market has experienced an astounding growth spurt and evolution, solidifying its position as a crucial element of the construction industry. Ready mix concrete, a specially formulated concrete mixture, is meticulously crafted in specialized manufacturing plants or factories before being dispatched to construction sites in a readily usable state. This modernized variant of on-site-mixed concrete offers numerous advantages over its conventional counterpart, including but not limited to superior quality, unwavering consistency, and unparalleled convenience.

The incessant demand for infrastructure development and urbanization is one of the primary catalysts driving the prodigious expansion of the Ready Mix Concrete market. As countries around the world continue to deposit enormous sums into the construction of highways, bridges, airports, and towering structures, the demand for ready mix concrete has skyrocketed. Ready mix concrete has unquestionably risen to the pinnacle of preference for innumerable construction projects thanks to its incomparable speed and efficiency in supplying copious quantities of concrete.

The incessant demand for infrastructure development and urbanization is one of the primary catalysts driving the prodigious expansion of the Ready Mix Concrete market. As countries around the world continue to deposit enormous sums into the construction of highways, bridges, airports, and towering structures, the demand for ready mix concrete has skyrocketed. Ready mix concrete has unquestionably risen to the pinnacle of preference for innumerable construction projects thanks to its incomparable speed and efficiency in supplying copious quantities of concrete.Increasing emphasis on sustainable construction practices is also a significant contributor to the market's booming growth. Utilizing ready mix concrete improves material control, reduces waste production, and effectively mitigates the negative environmental effects typically associated with on-site mixing. In a relentless pursuit of environmental friendliness, manufacturers have ingeniously incorporated sustainable constituents, including recycled aggregates and additional cementitious materials, into the fabric of their concrete concoctions, enhancing the product's overall environmental integrity.

The market landscape has been significantly impacted by technological advancements in the production and transportation of ready mix concrete. In batching facilities, cutting-edge automation and computer-controlled systems precisely regulate the mixing ratios, ensuring an unwaveringly consistent concrete mixture. The advent of innovative machineries, such as volumetric concrete mixers and mobile batching plants, has revolutionized on-site production capabilities, endowing construction projects with unprecedented adaptability and mitigating extortionate transportation expenses.

On the intensely competitive ready mix concrete market, a multitude of local and international actors vie for dominance. These market leaders are ardently focused on expanding production capacities, enhancing product quality, and delivering bespoke solutions that correspond flawlessly with the specific requirements of each project. The formation of mergers, acquisitions, and joint ventures is a pervasive strategy that these key market participants employ deftly to strengthen their market standing and expand their geographic footprint.

Despite the extremely optimistic growth prospects, the market faces a number of obstacles. Uncanny fluctuations in the prices of raw materials, including cement, aggregates, and admixtures, can have a significant impact on the profitability of ready mix concrete producers. Moreover, a multitude of stringent regulations pertaining to environmental preservation, worker safety, and transportation conformance represents a formidable obstacle for industry participants attempting to flourish in this dynamic market environment.

Driving factors

Increasing Infrastructure Development

The extraordinary increase in global demand for infrastructure development is the primary factor fueling the exponential growth of the ready mix concrete market. Governments and private entities are investing heavily in the construction of a vast array of vital structures, ranging from expansive road networks and awe-inspiring bridges to colossal buildings and cutting-edge airports. Inevitably, this burgeoning demand for ready mix concrete has experienced an unprecedented surge, given its unrivaled capacity to deliver copious quantities of concrete with unrivaled speed and efficiency, thereby solidifying its position as the preferred material for a vast array of construction projects.

Putting the Focus on Sustainable Construction

The market's trajectory is profoundly influenced by the growing emphasis on pursuing sustainable building practices. Utilization of ready-mixed concrete, with its inherent capacity to instill a greater degree of material control, unquestionably serves as an indispensable catalyst for minimizing waste generation and effectively mitigating the negative environmental effects typically associated with on-site mixing. Imbued with an unwavering commitment to environmental integrity, manufacturers have ingeniously incorporated sustainable constituents, such as recycled aggregates and supplementary cementitious materials, into the very fabric of their concrete creations. This conscientious endeavor has invariably succeeded in attracting a discerning clientele whose environmental awareness is unwaveringly fervent.

Technological Advancements

Technological advances have emerged as an undeniable linchpin in driving the ready mix concrete market to unprecedented growth and expansion. The introduction of cutting-edge automation systems, assiduously orchestrated within the confines of revered batching plants, results in the facilitation of unrivaled precision in mixing ratios, thereby guaranteeing an unwaveringly consistent mixture of ready mix concrete. Equipment innovations, most notably the introduction of volumetric concrete mixers and mobile batching plants, have effectively revolutionized on-site production capabilities, ushering in an era characterized by an unprecedented degree of flexibility while simultaneously mitigating the industry's historically exorbitant transportation costs.

Urbanization and Population Growth

Rapid urbanization and population growth have emerged as indisputable forces propelling the ready mix concrete market to stratospheric heights of prosperity, especially in regions with unparalleled allure such as Asia-Pacific. The unrelenting migration to urban centers, prompted by the allure of burgeoning opportunities, generates an insatiable demand for residential and commercial infrastructure, invariably propelling the exponential increase in demand for ready mix concrete. Government entities in emergent economies are unyieldingly committed to infrastructure development, continually channeling substantial investments that serve as potent propellers to impel the market to unprecedented growth. In addition, the convergence of escalating levels of disposable income and changing lifestyles has resulted in an unwavering demand for construction projects that are the epitome of modernity.

Restraining Factors

Price Variation of Raw Materials

The concrete industry is currently confronting one of its most formidable obstacles: the persistent fluctuations in raw material prices. Cement, grit, and aggregates, which are indispensable to the production of concrete, are perpetually subject to the capricious vagaries of supply and demand dynamics. The ever-changing nature of these price fluctuations impedes the ready mix concrete industry's ability to remain profitable.

To surmount this multifaceted challenge, we are unwaveringly committed to optimizing our vast supply chain network, ensuring a seamless flow of raw materials at prices that remain ferociously competitive. In addition, we invest heavily in innovative research and development initiatives, fervently investigating alternative materials with the uncanny ability to serve as suitable substitutes for conventional raw materials.

Environmental concerns and stringent concrete production and transportation regulations

The ready mix concrete industry is inextricably entangled in the complex web of stringent regulations and environmental concerns that permeate the concrete production and transportation sector. Regulatory bodies have emerged as the vanguards of a new era, imposing increasingly stringent regulations and complex requirements governing the very composition of concrete production and transportation.

To overcome this formidable obstacle, we invest heavily in the development of sustainable products, incorporating environmentally-friendly materials and production methods that are the epitome of sustainability.

Lack of Skilled Labor and Concrete Production and Handling Knowledge

Despite its unrelenting pursuit of excellence, the ready mix concrete industry is hampered by the widespread lack of specialized labor and expertise required for the precise artistry of concrete production and management. It is impossible to overstate the importance of qualified labor and knowledge in ensuring the superior quality of concrete production and management; their scarcity invariably results in the production of inferior goods and an exponential increase in costs.

To overcome this multifaceted challenge, we invest unreservedly in exhaustive training and development programs meticulously designed to unlock our employees' latent potential. In addition, we foster symbiotic collaborations with prestigious universities and vocational schools, ingeniously utilizing this channel to not only attract burgeoning talent to our industry but also equip them with the training and expertise required to master the intricate artistry of concrete production and handling.

Application Analysis

Due to its simple availability and superior quality compared to conventional concrete mixtures, the use of ready mix concrete has been acquiring immense popularity worldwide. The Infrastructure Segment dominates the market, accounting for the largest share, among the various application segments of ready mix concrete. This segment comprises construction activities related to the development of highways, airports, bridges, and tunnels, as well as other public infrastructure initiatives.

The Infrastructure Segment of the ready mix concrete market is primarily propelled by the accelerated economic growth of emerging economies. The prospering construction and infrastructure industries in nations such as China, India, and Brazil are increasing the demand for ready mix concrete. Increasing urbanization and population growth in these regions also contribute to the need for new infrastructure development.

Consumers have favored the Infrastructure Segment of ready mix concrete due to its durability, cost-effectiveness, and high performance. The ongoing trend of sustainable and ecological infrastructure development is also driving demand for ready mix concrete within the Infrastructure Segment.

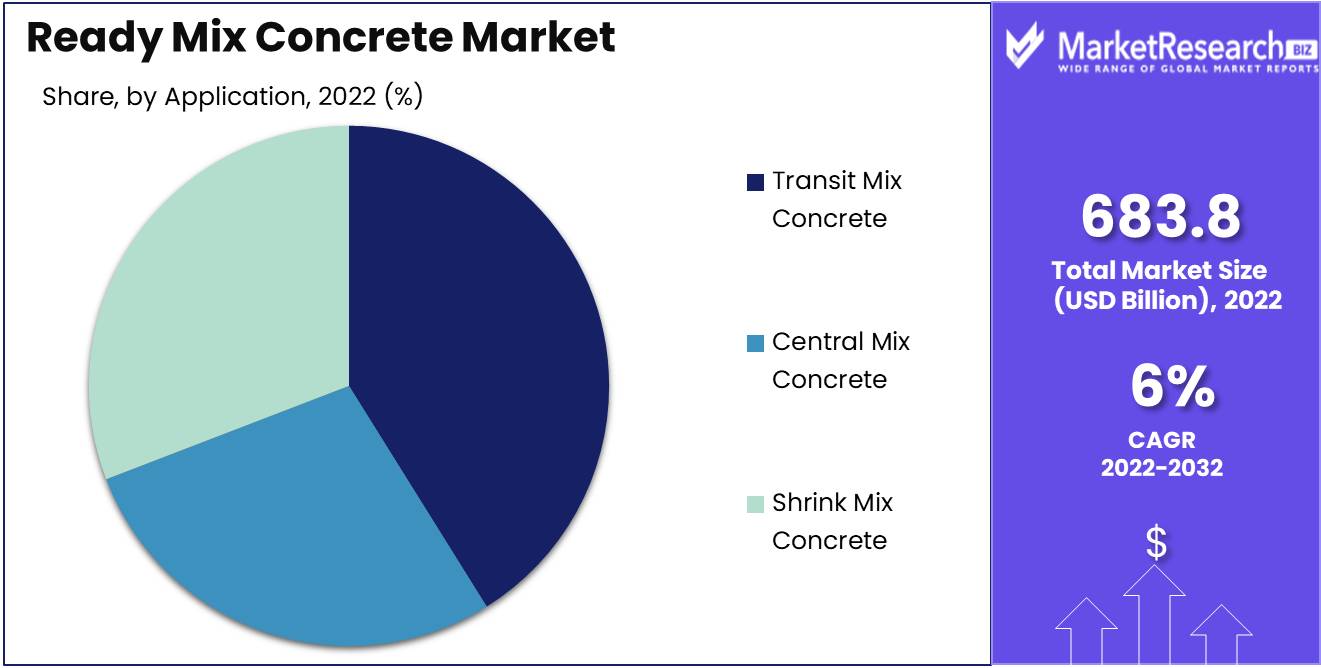

Product Type Analysis

The Transit Mixed Concrete Segment dominates the Ready Mix Concrete market, with a significant share. This segment consists of concrete formulations that are mixed centrally and then transported to the construction site using transit mixers.

The Transit Mixed Concrete Segment of the ready mix concrete market is driven by the expanding construction and infrastructure development in emerging economies. In these regions, transit mix concrete has gained popularity due to its superior quality and lower cost compared to traditional on-site mixed concrete.

Consumers prefer the Transit Mixed Concrete Segment due to its greater consistency, dependability, and transportability. The market demand for transit-mixed concrete is also being driven by the rising demand for quicker and more convenient construction techniques.

Delivery Model Analysis

The Onsite Mixed Segment dominates the Ready Mix Concrete market, with a significant share. This segment describes the batching and mixing of concrete mixtures on the construction site.

The demand for Onsite Mixed Segment of the ready mix concrete market is driven by the growing demand for quicker and more efficient construction techniques in developing economies. Due to its reduced transportation costs, customized formulations, and accessibility, onsite mixed concrete is preferred.

Consumers prefer Onsite Mixed Segment due to the adaptability and customization of the concrete mixture. Due to its reduced transportation costs and accessibility, this segment is also popular with small-scale construction projects.

Key Market Segments

by Application

- Commercial

- Residential

- Infrastructure

- Industrial utilities

by Product Type

- Transit Mix Concrete

- Central Mix Concrete

- Shrink Mix Concrete

by Delivery Model

- Onsite

- Offsite

Growth Opportunity

Development Countries' Construction Industry Expansion

Emerging economies such as India, China, and Brazil have been at the forefront of the construction industry's consistent expansion over the past several years. In these regions, there is an overwhelming demand for housing and infrastructure development due to rising population and urbanization. A demand for sustainable construction materials that can withstand extreme environmental conditions has also been led by accelerated industrialization and urbanization. Since RMC is an effective solution for both infrastructure and housing, it has become the concrete of choice in these markets.

Increasing Infrastructure Development Project Investments

Government spending on infrastructure development has increased, and smart city plans are on the rise. Flyovers, highways, bridges, and airports are examples of infrastructure developments that require significant RMC. Smart cities, on the other hand, rely significantly on high-quality and ready-to-use concrete materials, highlighting the significance of RMC.

Increasing demand for sustainable building materials

Increasingly conscious of the environmental impacts of conventional building materials, the construction industry is shifting toward sustainable materials. RMC provides an eco-friendly solution that can help reduce a construction project's carbon footprint. Its production process utilizes recycled materials and waste products such as fly ash and slag, making it a suitable option for construction companies seeking to implement sustainable processes.

Advancements in Concrete Design and Technology

Recent advancements in concrete technology have made it possible to manufacture ready-mixed concrete with superior qualities that can provide additional advantages, such as a longer longevity and greater strength. Now, high-performance RMC can be manufactured with minimal cement, thereby conserving resources and lowering CO2 emissions. These advancements have led to the development of optimized superplasticizers that can improve the RMC's flowability and pumpability, making it simpler to use and more durable.

Increasing Precast Concrete Construction Adoption

The increasing prevalence of precast concrete construction is due to its ability to save time, reduce construction costs, and maintain superior quality. The use of precast concrete eliminates the need for on-site compounding and shortens the duration of the project without sacrificing quality or precision. Thus, precast RMC is becoming a popular option for construction companies seeking an efficient and cost-effective method of constructing a building or infrastructure project.

Latest Trends

Increasing demand for self-consolidating concrete (SCC)

SCC, also known as self-consolidating concrete, is a type of concrete that does not require tamping, vibration, or mechanical consolidation. In recent years, this type of concrete has gained popularity due to its ability to flow readily into spaces and fill molds without requiring additional labor. SCC's high workability makes it an ideal material for structures with intricate designs and limited space.

Utilization of fiber-reinforced concrete (FRC) is growing

In the ready-mix concrete market, fiber-reinforced concrete is another prevalent trend. This type of concrete contains tiny filaments that enhance its tensile strength, ductility, and resistance to cracking. FRC is utilized in numerous applications, including roads, bridges, tunnels, and tall structures. FRC has become increasingly popular because it extends the service life of concrete structures.

Demand for high-performance concrete (HPC) is increasing

High-performance concrete (HPC) is designed to withstand adverse weather conditions, large loads, and corrosive environments due to its high strength and density. HPC is utilized for a variety of applications, including the construction of skyscrapers, dams, bridges, and other vital infrastructure projects. The demand for high-performance computing is increasing significantly due to its enhanced durability, decreased maintenance costs, and enhanced environmental performance.

Emergence of alternative concrete production materials

Traditional raw materials such as cement, grit, and gravel are continuously being replaced by the concrete industry with alternative raw materials. Alternative materials such as fly ash, slag, and pulverized stone are being utilized in the production of concrete in order to reduce its carbon imprint and increase its sustainability. In addition to reducing the cost of concrete production, the use of alternative materials also reduces the quantity of traditional basic materials required.

Digitalization and automation

The construction industry is adopting the digital age because digital solutions offer numerous advantages, such as increased efficiency, decreased costs, and enhanced safety. Drones, 3D printing, and digital simulation are currently widespread in the construction industry. As automated trucks and batching systems are employed to expedite the production process and reduce labor expenses, the use of digital solutions is also transforming the ready-mix concrete market.

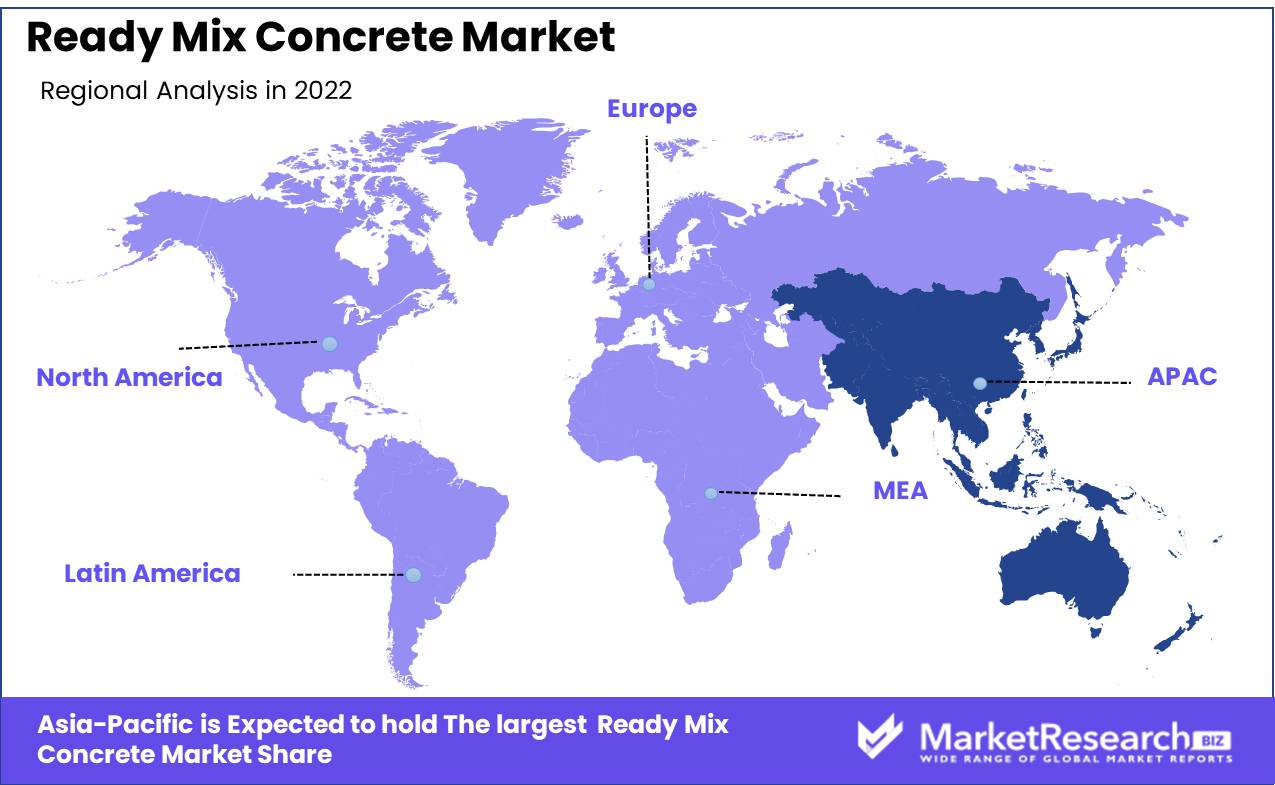

Regional Analysis

The Asia-Pacific region has experienced significant growth in the construction industry, which has contributed to the region's dominance in the ready mix concrete market. Several factors, including accelerated urbanization, population growth, infrastructure development, and rising investments in residential and commercial construction projects, have contributed to this dominance.

Due to their extensive construction efforts, countries such as China, India, Japan, Australia, and South Korea have experienced substantial demand for ready-mixed concrete. These countries have been investing in infrastructure development projects, such as roads, bridges, airports, residential structures, and commercial complexes, which have increased the demand for ready mix concrete.

In addition, the availability of aggregates, cement, and admixtures in the region has contributed to the growth of the ready-mix concrete market. The efficient transportation network and the presence of well-established concrete industry actors have also contributed to the Asia-Pacific region's market dominance.

Key Regions and Countries

North America

- US

- Canada

- Mexico

Western Europe

- Germany

- France

- The UK

- Spain

- Italy

- Portugal

- Ireland

- Austria

- Switzerland

- Benelux

- Nordic

- Rest of Western Europe

Eastern Europe

- Russia

- Poland

- The Czech Republic

- Greece

- Rest of Eastern Europe

APAC

- China

- Japan

- South Korea

- India

- Australia & New Zealand

- Indonesia

- Malaysia

- Philippines

- Singapore

- Thailand

- Vietnam

- Rest of APAC

Latin America

- Brazil

- Colombia

- Chile

- Argentina

- Costa Rica

- Rest of Latin America

Middle East & Africa

- Algeria

- Egypt

- Israel

- Kuwait

- Nigeria

- Saudi Arabia

- South Africa

- Turkey

- United Arab Emirates

- Rest of MEA

Key Players Analysis

In recent years, the global ready-mixed concrete market has expanded swiftly due to increased demand for construction materials and infrastructure development. The key players in the ready-mixed concrete market solutions are eminent construction companies that provide their clients with high-quality concrete solutions.

CEMEX is one of the most well-established players in the Ready Mix Concrete market. It is a Mexican company with a significant global presence, with more than 50,000 employees and more than 2700 facilities. Outstanding ready-mixed concrete has made the company a ubiquitous name in the construction industry.

LafargeHolcim, a Swiss company specializing in ready-mixed materials and construction solutions, is an additional significant player in the ready-mix concrete solutions market. The company is a global leader in the Ready Mix Concrete market due to its innovative and environmentally friendly solutions.

Buzzi Unicem, HeidelbergCement, Vicat SA, and Martin Marietta are four other significant players in the Ready Mix Concrete market. Due to their unique capabilities, these businesses have established a significant presence on the global ready-mix concrete market.

Top Key Players in Ready Mix Concrete Market

- ACC Limited

- Vicat SA

- Lafarge S.A.

- Buzzi Unicem S.p.A.

- Barney & Dickenson, Inc.

- W. Sidley, Inc.

- CEMEX S.A.B. de C.V.

- Italcementi Group

- UltraTech Cement Limited

- Holcim Ltd.

- HeidelbergCement

Recent Development

- In 2021, Breedon Group announced the acquisition of the UK Readymix business of CEMEX. This acquisition will contribute more than 200 million GBP in annual revenue to Breedon Group's business. The Readymix business in the United Kingdom comprises over 170 locations in England, Scotland, and Wales. This acquisition will make Breedon Group the largest independent construction materials business in the United Kingdom in terms of cement production capacity.

- In 2021, The CO2 mineralization technology was introduced by CarbonCure Technologies, a prominent provider of carbon capture and utilization for the concrete industry. This inventive technology utilizes captured CO2 as a feedstock in the production of concrete, resulting in a concrete mixture with a smaller carbon footprint. This technology is scalable and cost-effective, making it an attractive option for producers of concrete seeking to reduce carbon emissions.

- In 2021, BASF, a leading chemical company, and QUOIN, a startup specializing in the production of concrete, announced a partnership to develop sustainable concrete solutions. The partnership will concentrate on developing concrete mixtures with reduced carbon emissions, enhanced durability, and improved aesthetics. This partnership seeks to expedite the transition to sustainable construction by supplying the concrete industry with innovative solutions.

- In 2020, LafargeHolcim, a global authority in construction materials, introduced its ECOPact Green Concrete Range. This selection of environmentally friendly concrete options includes low-carbon concrete mixtures that reduce carbon emissions by up to 50 percent. The ECOPact Green Concrete Range is suitable for residential, commercial, and infrastructure construction, among other applications.

- In 2019, U.S. Concrete announced the acquisition of the North American Ready-Mix Concrete business of Votorantim Cimentos. This acquisition added more than 30 concrete production facilities to U.S. Concrete's existing operations, making it one of the nation's largest ready-mix concrete producers. This acquisition also gave U.S. Concrete access to new North American markets and customers.

Report Scope:

Report Features Description Market Value (2022) USD 683.8 Bn Forecast Revenue (2032) USD 1206.8 Bn CAGR (2023-2032) 6.0% Base Year for Estimation 2022 Historic Period 2016-2022 Forecast Period 2023-2032 Report Coverage Revenue Forecast, Market Dynamics, COVID-19 Impact, Competitive Landscape, Recent Developments Segments Covered By Application(Commercial, Residential, Infrastructure, Industrial utilities), By Product Type(Transit Mix Concrete, Central Mix Concrete, Shrink Mix Concrete), By Delivery Model(Onsite, Offsite) Regional Analysis North America – The US, Canada, & Mexico; Western Europe – Germany, France, The UK, Spain, Italy, Portugal, Ireland, Austria, Switzerland, Benelux, Nordic, & Rest of Western Europe; Eastern Europe – Russia, Poland, The Czech Republic, Greece, & Rest of Eastern Europe; APAC – China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Malaysia, Philippines, Singapore, Thailand, Vietnam, & Rest of APAC; Latin America – Brazil, Colombia, Chile, Argentina, Costa Rica, & Rest of Latin America; Middle East & Africa – Algeria, Egypt, Israel, Kuwait, Nigeria, Saudi Arabia, South Africa, Turkey, United Arab Emirates, & Rest of MEA Competitive Landscape ACC Limited, Vicat SA, Lafarge S.A., Buzzi Unicem S.p.A., Barney & Dickenson, Inc., W. Sidley, Inc., CEMEX S.A.B. de C.V., Italcementi Group, UltraTech Cement Limited, Holcim Ltd., HeidelbergCement Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) -

-

- ACC Limited

- Vicat SA

- Lafarge S.A.

- Buzzi Unicem S.p.A.

- Barney & Dickenson, Inc.

- W. Sidley, Inc.

- CEMEX S.A.B. de C.V.

- Italcementi Group

- UltraTech Cement Limited

- Holcim Ltd.

- HeidelbergCement