Polypropylene (PP) Homopolymer Market By processing Technology (Injection Molding, Film, Other Extrusion, Fiber, Others), By Application (Packaging, Electrical and Electronics, Textile, Automotive, Building and Construction, Others), By Region And Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, And Forecast 2023-2032

-

2838

-

May 2023

-

175

-

-

This report was compiled by Shreyas Rokade Shreyas Rokade is a seasoned Research Analyst with CMFE, bringing extensive expertise in market research and consulting, with a strong background in Chemical Engineering. Correspondence Team Lead-CMFE Linkedin | Detailed Market research Methodology Our methodology involves a mix of primary research, including interviews with leading mental health experts, and secondary research from reputable medical journals and databases. View Detailed Methodology Page

-

Quick Navigation

Report Overview

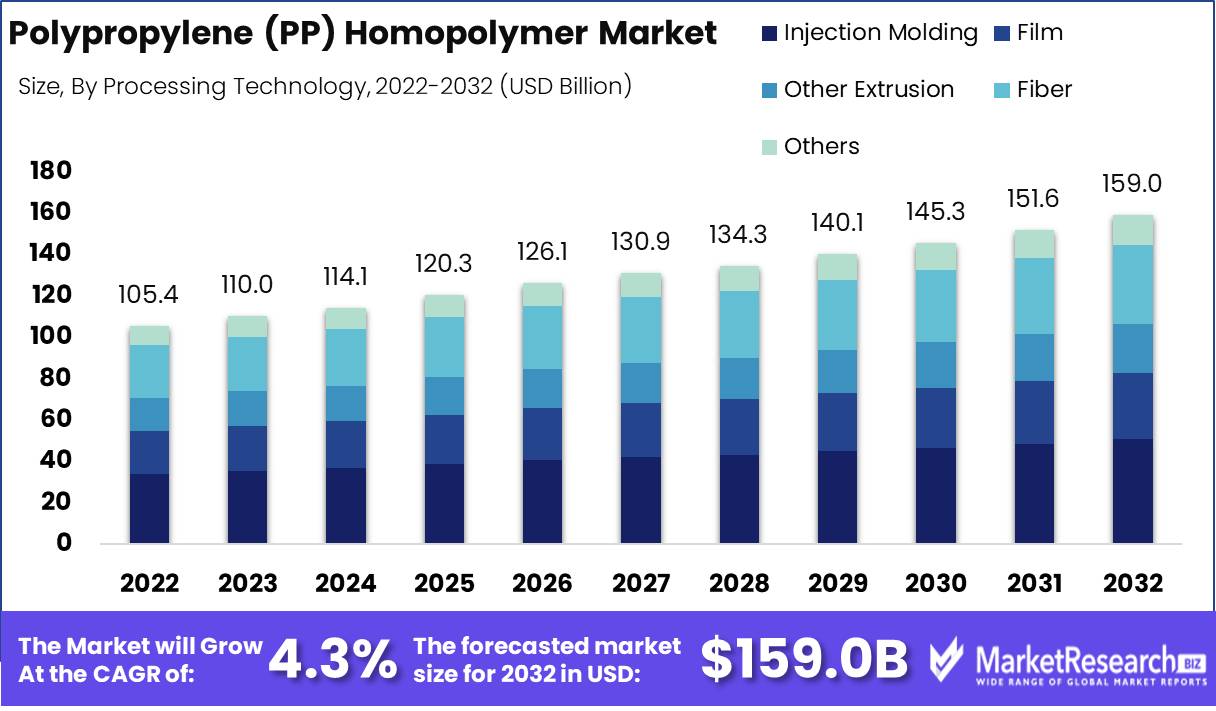

Polypropylene (PP) Homopolymer Market size is expected to be worth around USD 159.0 Bn by 2032 from USD 105.4 Bn in 2022, growing at a CAGR of 4.3% during the forecast period from 2023 to 2032.

Polypropylene (PP) Homopolymer's market has risen steadily, and analysts expect this trend to continue. Polypropylene homopolymer, a thermoplastic polymer with a high melting point and excellent chemical resistance, is used in many PP applications, from consumer items to industrial products. Its versatility makes it valuable in the polymer sector. Its high tensile strength, heat resistance, stiffness, and dimensional stability make it perfect for many Polypropylene (PP) applications. Injection, blow, and thermoforming have been successful in packaging, automotive parts, and appliances.

Polypropylene (PP) Homopolymer is one of the most essential materials nowadays for numerous reasons. First, Polypropylene (PP) excels in consumer and industrial products due to its high melting point and chemical resilience. Second, the low coefficient of friction aids mould flow, while the high rigidity and dimensional stability ensure that the finished goods satisfy specifications.

Technology has led to many improvements in the Polypropylene (PP) Homopolymer sector. New grades of Polypropylene (PP) Homopolymer with improved characteristics allow its usage in increasingly demanding applications. Processing technology has also made Polypropylene (PP) Homopolymer production more efficient and waste-free. Novel polymer mixes have expanded Polypropylene (PP) markets and uses. Manufacturers are investing in R&D to optimise manufacturing processes and find innovative solutions in the Polypropylene (PP) homopolymer market. Industries and manufacturers are using Polypropylene (PP) Homopolymer to improve product performance and durability.

Due to increased demand in bespoke injection moulding, fibre, and sheet extrusion, the Polypropylene (PP) Homopolymer market has risen consistently. Demand for recyclable and reusable packaging and lightweight, durable automobile components has also helped the market. Thus, appliances, building, and healthcare use the material more. Polypropylene (PP) homopolymer demand has risen due to industry desire for renewable energy and lightweight materials. Polypropylene (PP) Homopolymer production must address ethics. The industry must use sustainable raw materials.

Driving factors

Increasing Packaging Industry as a Driver

The surge in demand for Polypropylene (PP) homopolymer is largely attributable to the extraordinary expansion of the packaging industry. Because of its exceptional resistance to moisture and impact, this polymer is widely used in the production of packaging materials. In addition, due to its superior properties, it is an excellent choice for food packaging. This growth is being fueled by the expansion of e-commerce platforms, resulting in an increase in demand for Polypropylene (PP) homopolymer.

Growing Utilisation in the Automotive Industry

The demand for Polypropylene (PP) homopolymer is also significantly influenced by the automotive industry. Focusing on minimising the weight of their vehicles, automotive manufacturers have increased demand for lightweight components. With its low weight and high strength, Polypropylene (PP) homopolymer is preferred over other metals and alloys, contributing to the increase in demand for this polymer.

Alternative economical to other polymers

Homopolymer of polypropylene (PP) is a cost-effective alternative to other polymers, making it a desirable option for manufacturers. The exceptional properties of this polymer allow for its use in a wide variety of applications, including industrial components, consumer goods such as furniture, and household appliances, among others. This adaptability and affordability contribute significantly to the expansion of the market.

Regulatory Environment and New Technologies

Current regulatory conditions are favourable for the market for Polypropylene (PP) homopolymer. However, any alterations to the rules could have an effect on the market. For instance, stringent environmental regulations may result in a transition towards more eco-friendly materials, thereby impacting the demand for Polypropylene (PP) homopolymer. Emerging technologies such as biodegradable Polypropylene (PP) homopolymer could be a game-changer on the market, satisfying the growing demand for plastic alternatives that are more environmentally friendly.

Restraining Factors

Manufacturers' primary concern is fluctuating raw material costs.

Due to the volatility of raw material prices, the market for Polypropylene (PP) homopolymer faces significant obstacles. The prices of Polypropylene (PP) homopolymer are dependent on those of propylene monomer, which is derived from crude oil. The fluctuating price of crude oil carrie has a direct effect on the cost of Polypropylene (PP) homopolymer, making it difficult for manufacturers to maintain stable pricing for their final products. This price volatility has a negative impact on the profitability of producers and can hinder the development and expansion of the Polypropylene (PP) homopolymer market.

Availability of Alternatives

Polypropylene (PP) homopolymer is ubiquitous in numerous industries, including packaging, automotive, and construction, due to its superior durability, rigidity, and resistance to moisture. However, several alternative substitutes such as polyethylene (PE), polyethylene terephthalate (PET), and polyvinyl chloride (PVC) offer similar properties to Polypropylene (PP) homopolymer at a lower cost in some instances. The availability of substitutes has emerged as a significant factor restraining the growth of the Polypropylene (PP) homopolymer market, thereby increasing competition among manufacturers and decreasing their market share.

Environmental Impact

The Polypropylene (PP) homopolymer market is experiencing a rise in environmental impact and sustainability concerns. As a non-biodegradable material, the disposal of Polypropylene (PP) homopolymer can have severe environmental consequences, including soil, air, and water contamination. As a result, a number of nations have imposed stringent regulations regarding the disposal of Polypropylene (PP) homopolymer products, restricting the market's expansion. These regulations must be followed by manufacturers, increasing production costs and decreasing product demand.

Challenge of Strict Regulations

The market for Polypropylene (PP) homopolymer is hampered by the proliferation of regulations governing the use of plastics. The European Union and Canada have already prohibited single-use plastics, including straws and cutlery made of Polypropylene (PP) homopolymer, and other governments are anticipated to take similar action. The implementation of such measures can restrain the growth of the Polypropylene (PP) homopolymer market, requiring manufacturers to innovate and develop more environmentally friendly products in order to remain competitive.

By Processing Technology Analysis

The market for Polypropylene (PP) homopolymer has been shaped and dominated by the injection moulding processing technology, which has become the standard technique for producing high-precision, high-tolerance products. Injection moulding entails injecting molten Polypropylene (PP) homopolymer into a mould in order to obtain the desired product shape. This technique has widespread applications in industries such as packaging, automotive, and construction.

Polypropylene (PP) homopolymer adoption has been substantially influenced by the versatility of the injection moulding process. With the rise in consumer demand for bespoke and customised products, injection moulding has provided an unprecedented degree of design and customization flexibility. Consequently, there has been an increase in the adoption of injection moulding across industries, which has contributed to the expansion of the Polypropylene (PP) homopolymer market.

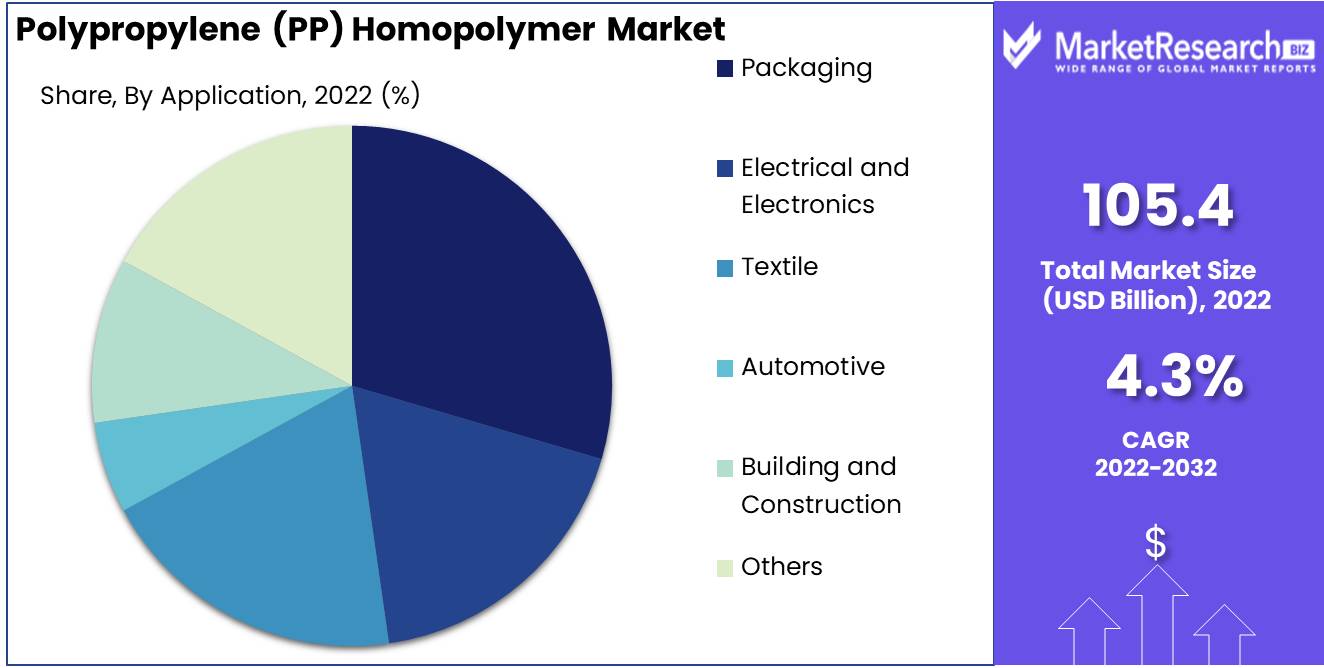

By Application Analysis

A significant factor propelling the expansion of the Polypropylene (PP) homopolymer market has been the rise of consumer preferences for lightweight and long-lasting goods. This is notably evident in industries such as the automotive and construction sectors, which require materials that are both durable and lightweight. With its ability to produce intricate shapes and designs, injection moulding has been instrumental in meeting the demand for such materials.

The packaging industry's use of Polypropylene (PP) homopolymer has been one of the market's most significant growth drivers. Particularly, the packaging segment has experienced significant growth due to consumer trends towards eco-friendly and sustainable packaging solutions. As environmental conservation awareness has increased, consumers have demanded more eco-friendly and sustainable packaging materials.

Polypropylene (PP) homopolymer packaging has emerged as a recyclable, cost-effective alternative to traditional packaging materials. As a result, the packaging segment is poised for growth, as the demand for sustainable packaging solutions continues to rise. This trend has been amplified by the rise of online purchasing platforms, which necessitate the use of robust and secure packaging materials to ensure the safe transportation of goods. Due to its affordability and recyclability, Polypropylene (PP) homopolymer packaging has gained popularity among online retailers.

Key Market Segments

By Processing Technology

- Injection Molding

- Film

- Other Extrusion

- Fiber

- Others

By Application

- Packaging

- Electrical and Electronics

- Textile

- Automotive

- Building and Construction

- Others

Growth Opportunity

Sustainable Packaging Solutions

As the global community seeks to reduce plastic waste and carbon footprints, sustainable packaging solutions have become a hot topic in recent years. The introduction of Polypropylene (PP) homopolymer, a versatile material with multiple functionalities, makes it an ideal choice for packaging solutions. Polypropylene (PP) homopolymer is an ideal material for developing sustainable packaging solutions due to its exceptional dimensional stability, resistance to high temperatures, light weight, and exceptional clarity.

The increasing prevalence of e-commerce and demand for environmentally favourable packaging

The rapid expansion of e-commerce businesses has led to a surge in demand for eco-friendly packaging, thereby bolstering the Polypropylene (PP) homopolymer market. As consumer awareness of eco-friendliness continues to increase, the demand for eco-friendly packaging solutions has skyrocketed, and biodegradable Polypropylene (PP) homopolymer is an ideal solution.

The Growing Desire for Biodegradable

The demand for biodegradable Polypropylene (PP) homopolymer is soaring due to the increasing demand for environmentally sustainable goods. Being readily degradable by microorganisms, biodegradable polymers have become an increasingly popular alternative to traditional plastics.

The greatest benefit of biodegradable Polypropylene (PP) homopolymer is that it offers the same properties as conventional Polypropylene (PP) homopolymer, a highly versatile packing material, without affecting the environment. Governments around the world are instituting stringent plastic usage regulations, paving the way for the exponential growth of biodegradable Polypropylene (PP) homopolymer.

Increasing Application

In the healthcare industry, Polypropylene (PP) homopolymer has become the preferred material for medical packaging due to its unique properties. The material has exceptional chemical resistance and can withstand extreme conditions, making it the material of choice for packaging of medical and pharmaceutical products.

As the demand for high-quality medical packaging continues to rise, the Polypropylene (PP) homopolymer market stands to gain. Polypropylene (PP) homopolymer is also extensively used in the production of medical devices such as syringes, surgical instruments, and catheters. As the global demand for healthcare services rises, the medical packaging segment of the Polypropylene (PP) homopolymer market is anticipated to experience significant growth.

Emerging Economies Possess Enormous Potential

In emerging economies such as India, China, and Brazil, the Polypropylene (PP) homopolymer market is expected to grow. These nations are presently experiencing rapid economic growth, which has led to an expansion of the middle class and a rise in consumerism. This has increased the demand for packaging materials such as Polypropylene (PP) homopolymer, as a consequence of the increased demand for consumer goods.

Moreover, these emerging economies have implemented stricter regulations regarding the use of plastic, resulting in an expansion of the market for biodegradable Polypropylene (PP) homopolymer. These societies offer new growth opportunities for the Polypropylene (PP) homopolymer market due to their increasing investments in infrastructure development and emphasis on sustainability.

Latest Trends

A progressively prevalent option for 3D printing applications

As 3D printing technology continues to acquire traction, there is a growing demand for printing materials with superior impact resistance, dimensional stability, and affordability. Due to its superior chemical resistance and recyclability, Polypropylene (PP) homopolymer has become a popular material for 3D printing applications in a variety of industries.

Increased Use of Polypropylene (PP) homopolymer

Advanced applications such as medical devices, aerospace, and defence are increasingly adopting Polypropylene (PP) homopolymer. Its extraordinary properties, which include high purity, biocompatibility, clarity, strength, stiffness, and resistance to stress and fatigue, make it the material of choice for manufacturing syringes, IV tubes, surgical instruments, and other medical devices. Similarly, its durability and rigidity make it an ideal material for the aerospace and defence industries.

Increasing Dependence of the Electrical and Electronics Industry

Due to the increasing demand for smartphones, tablets, laptops, and LED illumination, the electrical and electronics industry has become one of the largest consumers of Polypropylene (PP) homopolymer. Due to its excellent electrical insulation, flame resistance, and dimensional stability, this versatile material is extensively used to manufacture electrical and electronic components such as switches, connectors, and enclosures.

Pursuit of Excellence

The rising demand for Polypropylene (PP) homopolymer and the need to meet diverse consumer demands have prompted manufacturers to make substantial investments in R&D. The objective is to perpetually enhance the mechanical, chemical, and thermal properties of Polypropylene (PP) homopolymer. The goal is to create a material that is more durable, flexible, and able to withstand extreme conditions in order to satisfy the increasing demands of various industries.

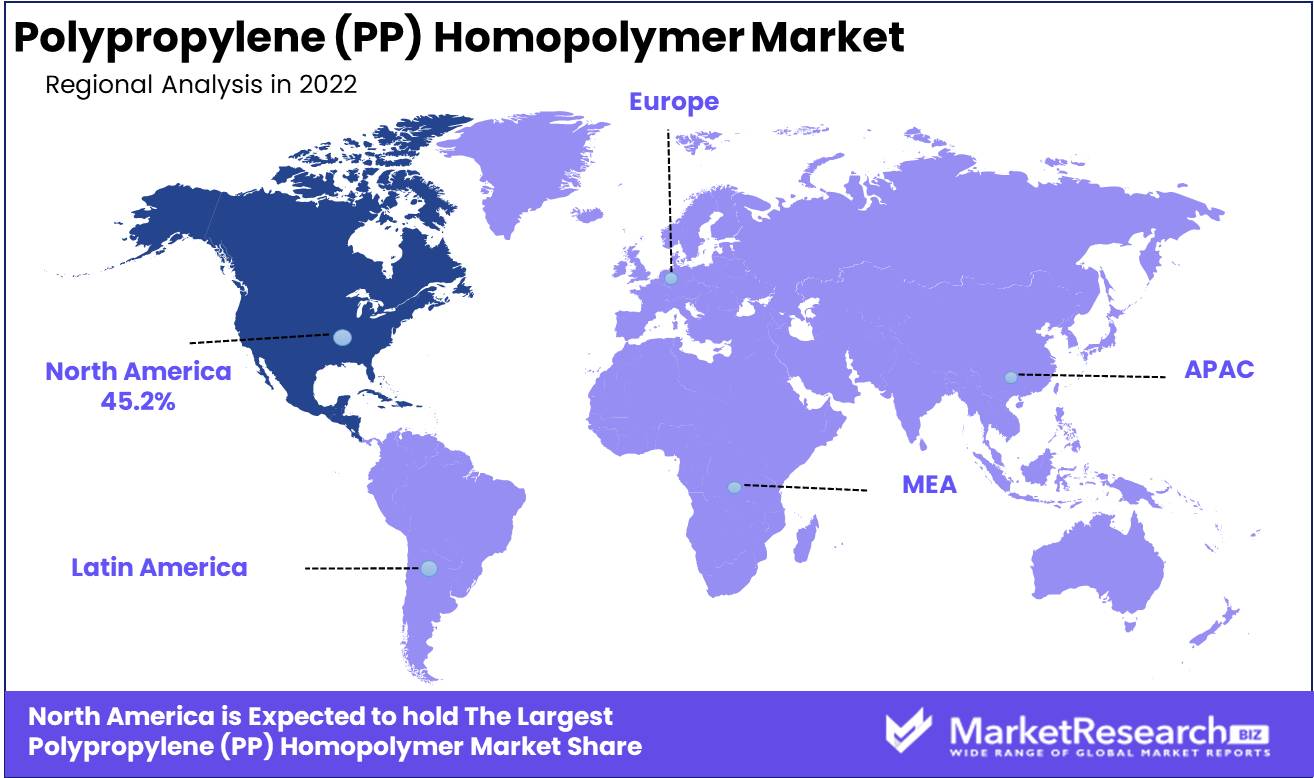

Regional Analysis

We are privileged to make a public announcement of exceptional significance that has global repercussions. Asia-Pacific has emerged as the world's largest regional market by 2021, accounting for more than fifty percent of the world's revenue. This extraordinary and historic milestone not only represents the unstoppable expansion of Asia Pacific's global influence, but also the region's unwavering dedication to adopting cutting-edge technologies and innovative business models.

Asia-Pacific's growing dominance has been fueled in large part by its prospering manufacturing industry. China, Japan, and South Korea are home to some of the world's most advanced manufacturing facilities, which produce everything from high-tech electronics to cutting-edge automobiles. This has not only boosted the region's economy but also had a favourable impact on the global supply chain, elevating Asia Pacific's status as an economic superpower.

Asia-Pacific has been quick to embrace the plethora of benefits brought about by digital transformation. Governments and corporations are making massive investments in cutting-edge technologies, such as artificial intelligence, 5G networks, and the Internet of Things, thereby creating an ideal environment for entrepreneurs and small businesses to drive innovation and disrupt conventional business models.

The Asia-Pacific region has also excelled in its infrastructure development. The region has made enormous investments in the construction of advanced highways, airports, and seaports, which have resulted in a significant increase in domestic and international commerce, thereby enhancing the region's overall efficacy and productivity. The Asia-Pacific region's burgeoning and prosperous middle class is an indispensable driver of its economic development. As an increasing number of individuals enter the middle class, their disposable income rises, resulting in a surge in consumer purchasing, which ultimately propels the region's economic development to new heights.

Key Regions and Countries

North America

- US

- Canada

- Mexico

Western Europe

- Germany

- France

- The UK

- Spain

- Italy

- Portugal

- Ireland

- Austria

- Switzerland

- Benelux

- Nordic

- Rest of Western Europe

Eastern Europe

- Russia

- Poland

- The Czech Republic

- Greece

- Rest of Eastern Europe

APAC

- China

- Japan

- South Korea

- India

- Australia & New Zealand

- Indonesia

- Malaysia

- Philippines

- Singapore

- Thailand

- Vietnam

- Rest of APAC

Latin America

- Brazil

- Colombia

- Chile

- Argentina

- Costa Rica

- Rest of Latin America

Middle East & Africa

- Algeria

- Egypt

- Israel

- Kuwait

- Nigeria

- Saudi Arabia

- South Africa

- Turkey

- United Arab Emirates

- Rest of MEA

Key Players Analysis

Polypropylene (PP) homopolymer is a thermoplastic polymer with a wide range of applications in the industrial sector. Composed of a single monomer, propylene, it possesses a high level of rigidity, remarkable impact resistance, and exceptional chemical resistance. These characteristics make it suitable for a wide variety of applications.

The market for Polypropylene (PP) homopolymer is expanding at an unprecedented rate, with numerous market leaders competing for a larger share. Diverse market participants are frequently engaged in a variety of endeavours, such as cutting-edge research and development, groundbreaking product innovation, and expansion strategies to strengthen their market presence.

Exxon Mobil Corporation, LyondellBasell Industries Holdings B.V., SABIC, Braskem, Total S.A., Borealis AG, and Trinseo S.A. are among the market leaders in the Polypropylene (PP) homopolymer industry. These entities are concentrating on innovation, quality enhancement, and product development to keep up with the burgeoning demand for Polypropylene (PP) homopolymer across various industries, such as packaging, automotive, construction, and healthcare.

Exxon Mobil Corporation has firmly established itself as one of the top competitors in the Polypropylene (PP) homopolymer market, offering a wide variety of products that are suitable for a variety of industrial applications. A novel series of Polypropylene (PP) homopolymers with superior clarity, processability, and environmental sustainability was introduced by the company recently. Similarly, LyondellBasell Industries Holdings B.V. is a key entity that offers a diverse array of Polypropylene (PP) homopolymer products for a variety of applications. With a substantial global presence, the company is persistently seeking to increase its market share through the formation of strategic partnerships and alliances.

Top Key Players in Polypropylene (PP) Homopolymer Market

- Braskem S.A.

- LyondellBasell Industries N.V.

- Reliance Industries Limited

- The Dow Chemical Company

- Total Petrochemicals USA Inc.

- C.Y. Chemical Corporation

- Sasol Limited.

- IRPC Public Company Limited.

- The Polyolefin Company Pte Ltd.

- National Petrochemical Industrial Company

Recent Development

In 2021, LyondellBasell will introduce Purell RP320M, a new PP homopolymer grade with superior stiffness and impact resistance for injection-molded packaging and consumer goods.

In 2020, Braskem introduced SP766, a new grade of PP homopolymer with enhanced mechanical properties and suitability for the manufacture of lids and closures for the food and beverage industry.

In 2019, ExxonMobil introduced two new grades of PP homopolymer Achieve Advanced PP5302G1 and Achieve Advanced PP3155G1, which offer enhanced impact resistance and stiffness, respectively.

Report Scope

Report Features Description Market Value (2022) USD 105.4 Bn Forecast Revenue (2032) USD 159.0 Bn CAGR (2023-2032) 4.3% Base Year for Estimation 2022 Historic Period 2016-2022 Forecast Period 2023-2032 Report Coverage Revenue Forecast, Market Dynamics, COVID-19 Impact, Competitive Landscape, Recent Developments Segments Covered By processing Technology: Injection Molding, Film, Other Extrusion, Fiber, Others

By Application: Packaging, Electrical and Electronics, Textile, Automotive, Building and Construction, OthersRegional Analysis North America – The US, Canada, & Mexico; Western Europe – Germany, France, The UK, Spain, Italy, Portugal, Ireland, Austria, Switzerland, Benelux, Nordic, & Rest of Western Europe; Eastern Europe – Russia, Poland, The Czech Republic, Greece, & Rest of Eastern Europe; APAC – China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Malaysia, Philippines, Singapore, Thailand, Vietnam, & Rest of APAC; Latin America – Brazil, Colombia, Chile, Argentina, Costa Rica, & Rest of Latin America; Middle East & Africa – Algeria, Egypt, Israel, Kuwait, Nigeria, Saudi Arabia, South Africa, Turkey, United Arab Emirates, & Rest of MEA Competitive Landscape Braskem S.A., LyondellBasell Industries N.V., Reliance Industries Limited, The Dow Chemical Company, Total Petrochemicals USA Inc., C.Y. Chemical Corporation, Sasol Limited., IRPC Public Company Limited., The Polyolefin Company Pte Ltd., National Petrochemical Industrial Company Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) -

-

- Braskem S.A.

- LyondellBasell Industries N.V.

- Reliance Industries Limited

- The Dow Chemical Company

- Total Petrochemicals USA Inc.

- C.Y. Chemical Corporation

- Sasol Limited.

- IRPC Public Company Limited.

- The Polyolefin Company Pte Ltd.

- National Petrochemical Industrial Company