Polyaryletherketone Market By Type(Polyetheretherketone( PEEK), Polyetherketone(PEK)), By Application(Automotive, Industrial and General Engineering, Other), By Region And Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, And Forecast 2023-2032

-

26258

-

Jul 2023

-

183

-

-

This report was compiled by Shreyas Rokade Shreyas Rokade is a seasoned Research Analyst with CMFE, bringing extensive expertise in market research and consulting, with a strong background in Chemical Engineering. Correspondence Team Lead-CMFE Linkedin | Detailed Market research Methodology Our methodology involves a mix of primary research, including interviews with leading mental health experts, and secondary research from reputable medical journals and databases. View Detailed Methodology Page

-

Quick Navigation

Report Overview

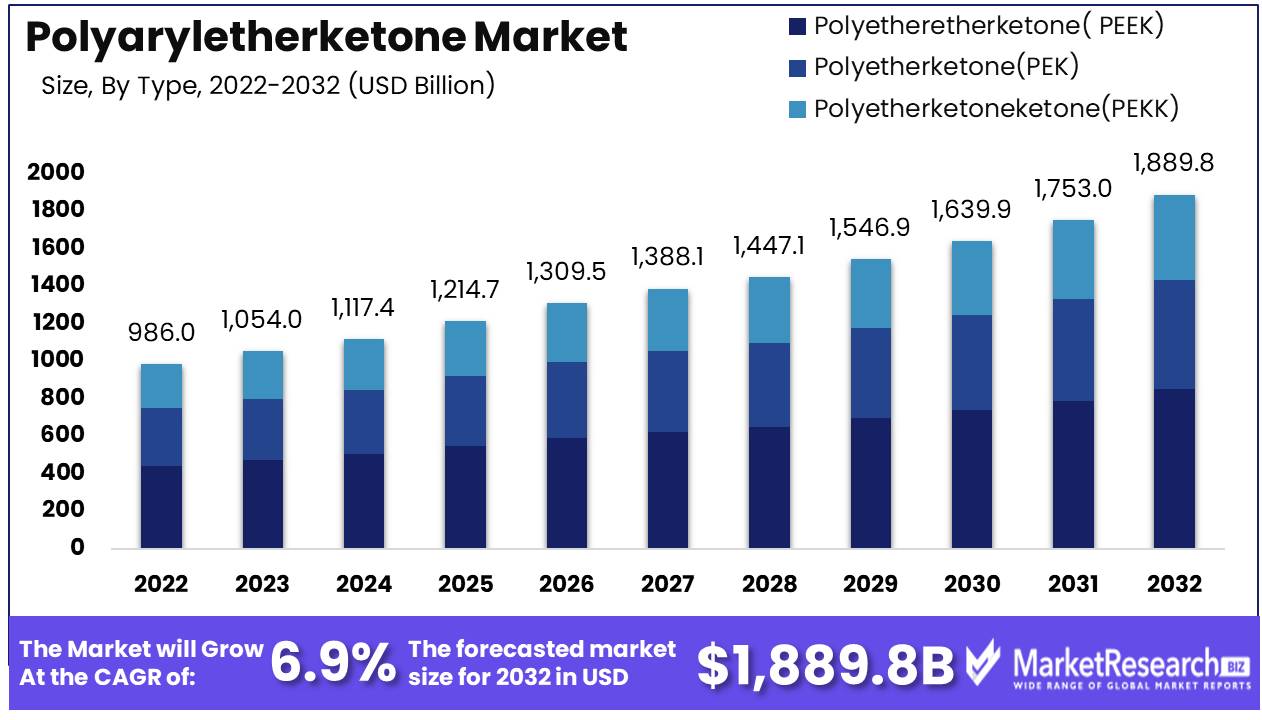

Polyaryletherketone Market size is expected to be worth around USD 1,889.8 Bn by 2032 from USD 986.0 Bn in 2022, growing at a CAGR of 6.9% during the forecast period from 2023 to 2032.

The Polyaryletherketone Market, also known as the precision agriculture market, is defined as the application of cutting-edge technologies to improve the efficacy and productivity of agricultural practices. Its primary objective is to optimize the use of resources like water, fertilizer, and pesticides while minimizing their environmental impact. By employing precision agriculture techniques, farmers can better comprehend their fields, monitor crop health, and maximize yields based on data-driven decisions.

The significance of the paek market cannot be emphasized enough. Polyaryletherketone Market techniques allow farmers to increase crop yields, decrease waste, and increase profits. Consequently, the paek market plays an essential role in assuring the food security and sustainability of future generations.

Significant innovations in the Polyaryletherketone Market have transformed conventional farming techniques. Utilizing remote sensing technologies, such as drones and satellites, to capture data about crop health, soil conditions, and weather patterns is one such innovation. This data can then be analyzed to identify enhancement areas and optimize farming practices.

There have been significant public and private investments in the Polyaryletherketone Market. Numerous agricultural technology firms have emerged, offering cutting-edge solutions such as soil sensors, intelligent irrigation systems, and AI-powered crop analytics platforms. These investments have resulted in the incorporation of paek market technologies into a variety of products and services provided by agricultural suppliers, equipment manufacturers, and even insurers.

Driving factors

Technological and Processing Advances in Polymer

PAEK, being a high-performance polymer, possesses remarkable mechanical, thermal, and chemical resistance properties. These properties make it an ideal material for demanding applications in industries such as aerospace, automotive, electronics, and oil and gas. Continuous advances in polymer technology and refining methods have fueled the growth of the PAEK market.

Multiple processes, including extrusion, injection molding, and compression molding, can be used to create PAEK polymer. These techniques allow for the production of complex components with precise dimensions, thereby providing engineers with a vast array of design options. PAEK is favored in industries where lightweight, high-strength components are required due to its ability to be fabricated into intricate shapes and forms.

Aerospace and Automotive Sector Development

The aerospace and automotive industries are experiencing significant growth, which is propelling the demand for high-performance materials such as PAEK. PAEK is utilized in the aerospace industry for components of aircraft engines, structural components, and electrical connectors, among other applications. Its lightweight nature contributes to the overall weight reduction of the aircraft, thereby enhancing fuel efficiency, increasing payload capacity, and decreasing emissions.

Likewise, PAEK is gaining popularity in the automotive industry due to its superior properties, which include high strength, chemical resistance, and exceptional dimensional stability. It is utilized in vital components such as engine components, transmission systems, electrical connectors, and lightweight structural components. The automotive industry's drive for fuel efficiency and emission reduction has bolstered the demand for PAEK as an alternative to traditional materials.

Demand for Heat and Chemical Resistance Continues to Grow

PAEK stands out due to its extraordinary heat and chemical resistance in a market where materials that can withstand extreme conditions are in high demand. Industries operating in severe environments, such as oil and gas, chemical processing, and electrical & electronics, require materials that can maintain their properties despite high temperatures and chemical exposure.

PAEK is a desirable option for these industries due to its exceptional thermal stability and resistance to a broad range of chemicals. It provides superior performance and enables apparatus and components to operate reliably in demanding environments, thereby extending their longevity.

Sustainability and energy efficiency are gaining importance.

There has been a significant transition toward sustainability and energy efficiency across industries in recent years. PAEK materials, which are extremely durable and long-lasting, contribute to the sustainable practices of a variety of industries. Utilizing lightweight PAEK components reduces petroleum consumption in transportation applications, thereby reducing carbon emissions.

In addition, PAEK's superior chemical resistance reduces the need for frequent replacements and restorations, resulting in less waste. PAEK's recyclability ensures that it can be reintroduced into the production cycle, thus fostering a circular economy.

Restraining Factors

Limited Access to Primary Materials

The potential scarcity of raw materials is another factor that could hinder the expansion of the Polyaryletherketone Market. PAEKs are derived from a mixture of aromatic compounds; therefore, guaranteeing a stable supply chain is crucial for achieving sustainable growth.

To overcome this obstacle, PAEK manufacturers, raw material suppliers, and research institutions can form proactive partnerships. These partnerships can explore alternative feedstocks and develop efficient sourcing and extraction techniques. In addition, concerted efforts toward recycling and repurposing PAEK materials can help reduce the demand for virgin raw materials, thereby easing the pressure on their availability.

Compliance and Regulatory Requirements

The Polyaryletherketone Market operates under a regulatory structure designed to assure product safety, environmental sustainability, and consumer protection. While these regulations are essential, their complexity and potential impact on production, distribution, and marketing strategies can present obstacles.

To successfully navigate the regulatory landscape, PAEK manufacturers must develop a comprehensive understanding of compliance requirements and integrate them proactively into their processes. Close collaboration with regulatory authorities, industry associations, and relevant subject matter experts can help identify potential gaps and align practices with applicable standards. Adopting sustainable practices, such as responsible waste management and environmental stewardship, not only ensures compliance but also improves brand reputation, thereby attracting environmentally conscious customers.

Type Analysis

The PEEK (Polyetheretherketone) segment dominates the Polyaryletherketone Market.

The Polyetheretherketone (PEEK) segment continues to dominate the Polyaryletherketone Market, with no symptoms of slowing down. PEEK is a polymer with superior thermal resistance, mechanical strength, and chemical resistance. It is utilized extensively in numerous industries, including aerospace, automotive, electronics, and the healthcare sector.

Emerging economies' economic growth is one of the most important factors propelling the paek market. As these nations continue to experience accelerated economic growth, the demand for advanced materials that can withstand high temperatures and harsh environments increases. PEEK satisfies all requirements, making it the material of choice for many manufacturers.

In addition to consumer trends and behavior, the dominance of the PEEK segment is also significantly influenced by consumer trends and behavior. As consumers become more aware of the advantages of high-performance materials, they demand durable, dependable, and long-lasting products. PEEK satisfies these specifications and exceeds them, making it a popular option among consumers.

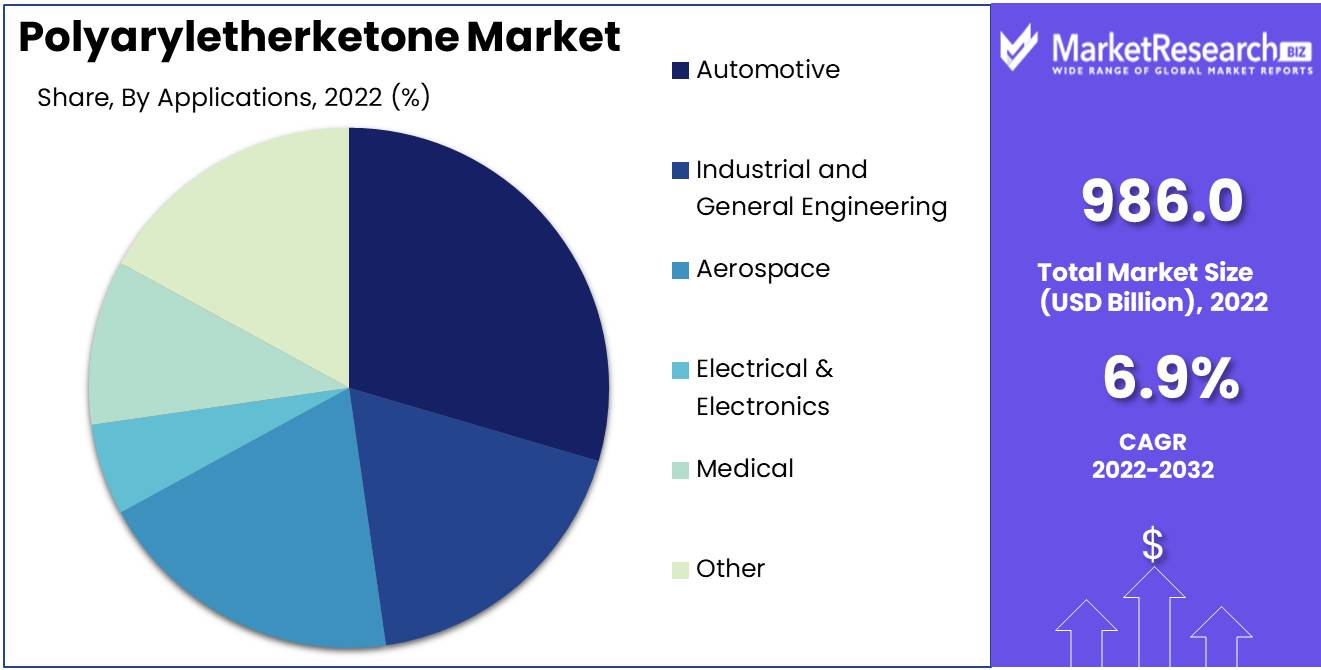

Application Analysis

Automotive Market Segment Dominates the Polyaryletherketone Market

When it comes to the paek market, the automotive sector holds the spotlight. The increasing demand for high-performance materials in the automotive industry is propelling the market expansion of PAEK. PEEK is predominantly utilized by the automotive industry for engine components, electrical connectors, fuel systems, and interior components.

Similar to the Paek market as a whole, economic development in emerging economies plays a significant role in the automotive segment's dominance. As these economies continue to expand, there is a growing demand for fuel-efficient, durable, and dependable vehicles. PEEK is an ideal material for automotive applications due to its exceptional thermal stability, chemical resistance, and mechanical strength.

Consumer trends and behavior also contribute to the automotive segment's market dominance in PEEK. In response to the growing demand for eco-friendly vehicles, manufacturers are searching for lightweight materials that can reduce fuel consumption and emissions. With its low density and high strength-to-weight ratio, PEEK is an ideal material.

Key Market Segments

By Type

- Polyetheretherketone( PEEK)

- Polyetherketone(PEK)

- Polyetherketoneketone(PEKK)

By Application

- Automotive

- Industrial and General Engineering

- Aerospace

- Electrical & Electronics

- Medical

- Other

Growth Opportunity

Initiatives for Accelerated Research and Development

Accelerating research and development initiatives represents one of the main growth opportunities in the Polyaryletherketone Market. Manufacturers can meet the growing demand for this versatile material by intensifying their efforts to develop and optimize cost-effective production methods for PAEK. Investing in R&D will enable the discovery of new methods to improve PAEK's performance characteristics, thereby increasing the material's desirability across multiple industries.

Development of the Aerospace Industry

There is significant potential for PAEK's expansion into this lucrative sector due to the aerospace industry's constant development and growth. PAEK is an ideal material for aerospace applications on account of its superior mechanical properties, high-temperature resistance, and low weight. By collaborating with aerospace manufacturers, PAEK producers are able to tap into this expanding market and offer customized solutions that meet the industry's stringent requirements.

Penetration of the Automotive Industry

The automotive sector provides the Polyaryletherketone Market with an additional growth opportunity. PAEK becomes an attractive option as the industry undergoes a paradigm shift toward lightweight materials for increased fuel efficiency and enhanced performance. Its extraordinary strength, durability, and ability to withstand high temperatures make it a viable alternative to conventional materials in engine parts, electrical connectors, and fuel systems, among other automotive components.

Latest Trends

The Expansion of PEEK and PAEK Materials

Due to their exceptional mechanical, chemical, and thermal properties, PEEK and PAEK materials have experienced extraordinary growth in recent years. These cutting-edge polymers have excellent resistance to chemicals, high temperatures, wear, and abrasion. Their inherent combustion retardancy, low smoke generation, and high strength-to-weight ratio make them highly desirable industrial materials.

PAEK demand in the aerospace and automotive industries

Due to the extraordinary performance characteristics of PAEK materials, the aerospace and automotive industries have emerged as major consumers. PAEK's low weight, high strength, and durability make it an ideal material for manufacturing aircraft and automobile components. PAEK materials are revolutionizing the way these industries operate, from engine components to structural elements, by providing improved fuel efficiency, reduced emissions, and enhanced overall performance.

Utilization of PAEK in the Oil and Gas Industry

PAEK-based composites and blends are widely used in the oil and gas industry, predominantly due to their ability to withstand extreme conditions. PAEK possesses excellent resistance to harsh chemicals, hydrocarbons, and corrosive substances, making it an ideal material for manufacturing drilling equipment, gaskets & seals, and downhole components. Its high mechanical strength, low coefficient of friction, and excellent dimensional stability contribute to an increase in operational efficiency and a lengthening of the equipment's service life.

PAEK Drives the Rise of 3D Printing and Additive Manufacturing

PAEK materials have emerged as one of the most desirable alternatives for 3D printing and additive manufacturing technologies, which have disrupted conventional manufacturing processes. The ability to precisely engineer complex geometries and fabricate functional prototypes with PAEK polymers has expanded the design and manufacturing landscape. This development has accelerated product development cycles, reduced material waste, and enabled the production of customized parts with superior performance characteristics.

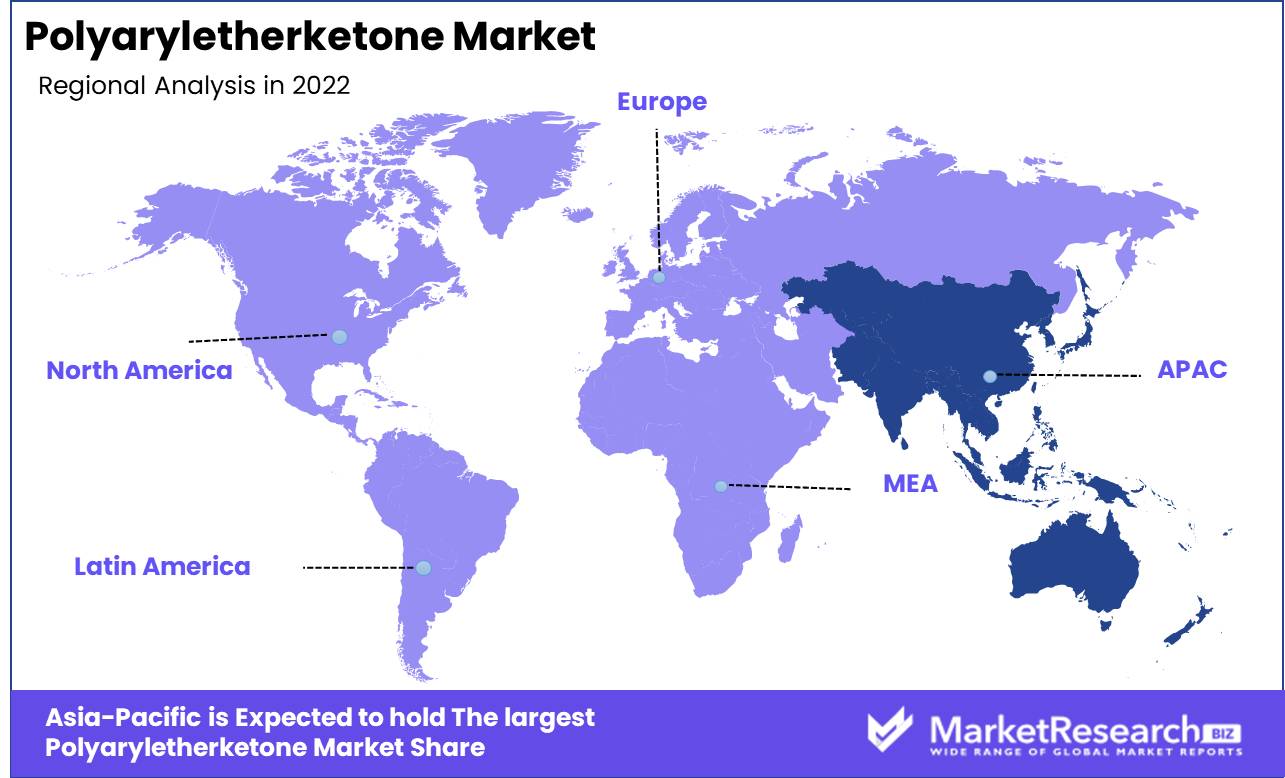

Regional Analysis

Asia-Pacific Region Dominates the Paek Market

The Paek market, a thriving industry that encompasses a wide range of products and services, has seen significant growth and development in the Asia-Pacific region. This growth can be attributed to various factors, such as increasing demand for Paek products, advancements in manufacturing technologies, and a favorable business environment.

One of the key drivers behind the Asia-Pacific region's dominance in the Paek market is its vast consumer base. With a population of over 4.5 billion people, the region offers a vast market for Paek products and services. This large consumer base provides ample opportunities for businesses to expand their operations and tap into new markets.

Furthermore, the Asia-Pacific region has been at the forefront of technological advancements, constantly pushing the boundaries of innovation. This has resulted in the development of state-of-the-art manufacturing processes and cutting-edge technologies, allowing businesses in the region to produce high-quality Paek products that meet global standards.

Additionally, the Asia-Pacific region benefits from a favorable business environment characterized by supportive government policies, robust infrastructure, and an abundance of skilled labor. These factors create an ideal ecosystem for businesses to thrive and seize opportunities in the Paek market.

Key Regions and Countries

North America

- US

- Canada

- Mexico

Western Europe

- Germany

- France

- The UK

- Spain

- Italy

- Portugal

- Ireland

- Austria

- Switzerland

- Benelux

- Nordic

- Rest of Western Europe

Eastern Europe

- Russia

- Poland

- The Czech Republic

- Greece

- Rest of Eastern Europe

APAC

- China

- Japan

- South Korea

- India

- Australia & New Zealand

- Indonesia

- Malaysia

- Philippines

- Singapore

- Thailand

- Vietnam

- Rest of APAC

Latin America

- Brazil

- Colombia

- Chile

- Argentina

- Costa Rica

- Rest of Latin America

Middle East & Africa

- Algeria

- Egypt

- Israel

- Kuwait

- Nigeria

- Saudi Arabia

- South Africa

- Turkey

- United Arab Emirates

- Rest of MEA

Key Players Analysis

Victrex plc holds a leading position in the PAEK market. Victrex has established itself as an innovator with more than four decades of industry experience, supplying solutions for mission-critical applications in the aerospace, automotive, electronics, energy, and medical industries. VICTREX PEEK, the company's flagship product, has exceptional chemical resistance, resistance to high temperatures, and outstanding mechanical properties.

Solvay is an additional significant player in the PAEK market, offering an extensive selection of specialty polymers and advanced composite materials. Solvay's PAEK portfolio includes products for the automotive, aerospace, oil and gas, and healthcare industries, such as KetaSpire®, AvaSpire®, and Torlon®. Solvay, a corporation with a global presence and a strong commitment to sustainable development, perpetually focuses on minimizing the environmental impact of its operations while providing innovative solutions to its customers.

Evonik produces high-performance PAEK polymers actively. VESTAKEEP® is widely used in a variety of applications, including medical, automotive, and oil and gas. Evonik's dedication to continuous innovation ensures that its products meet the stringent requirements of numerous industries.

Celanese Corporation is a market leader in the manufacture of specialty materials such as PAEK polymers. Their Amodel® polyphthalamide (PPA) polymers possess exceptional heat resistance, dimensional stability, and mechanical strength, making them suitable for a wide range of applications.

Top Key Players in Paek Market

- Victrex plc.

- Solvay

- Evonik

- Celanese Corporation

- Gharda Chemicals Ltd.

- Ensinger

- Lehmann&Voss&Co.

- Prototype & Plastic Mold Company Inc.

- Caledonian Industries Ltd.

- Toray Advanced Composites

- Jrlon Inc.

- Tri-Mack Plastics Manufacturing Corporation

- RTP Company

- The Mitsubishi Chemical Advanced Materials

- Arkema

- Nanoshel LLC

- Panjin Zhongrun Chemical Co. Ltd

Recent Development

- In 2023, HeiQ as a renowned company announced its intention to launch an innovative paek product. This innovative product promises to revolutionize the industry by incorporating sustainable materials and production techniques, thereby establishing new standards for eco-conscious consumers.

- In 2022, Nanotex announced its plans to expand its portfolio, introducing a wide range of new products and services. As a pioneer in the industry, Nanotex is continuously stretching boundaries and embracing innovation to provide customers with superior paek solutions, thereby strengthening its position as a market leader.

- In 2021, The paek market made a major step toward accessibility and affordability when Evonik announced the launch of a new brand designed to offer more affordable Paek options. Recognizing the significance of making high-quality products accessible to a larger audience, Evonik strives to meet the needs of price-conscious consumers without sacrificing performance or durability.

- In 2020, Mitsubishi Chemical made headlines with the acquisition of a reputable Paek product provider in a strategic move to broaden its product range and establish a stronger presence in the Paek market. This acquisition not only broadens Mitsubishi Chemical's product offerings but also positions them as a key player able to provide comprehensive solutions to satisfy the industry's evolving needs.

Report Scope

Report Features Description Market Value (2022) USD 986.0 Bn Forecast Revenue (2032) USD 1,889.8 Bn CAGR (2023-2032) 6.9% Base Year for Estimation 2022 Historic Period 2016-2022 Forecast Period 2023-2032 Report Coverage Revenue Forecast, Market Dynamics, COVID-19 Impact, Competitive Landscape, Recent Developments Segments Covered By Type(Polyetheretherketone( PEEK), Polyetherketone(PEK)), By Application(Automotive, Industrial and General Engineering, Other) Regional Analysis North America – The US, Canada, & Mexico; Western Europe – Germany, France, The UK, Spain, Italy, Portugal, Ireland, Austria, Switzerland, Benelux, Nordic, & Rest of Western Europe; Eastern Europe – Russia, Poland, The Czech Republic, Greece, & Rest of Eastern Europe; APAC – China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Malaysia, Philippines, Singapore, Thailand, Vietnam, & Rest of APAC; Latin America – Brazil, Colombia, Chile, Argentina, Costa Rica, & Rest of Latin America; Middle East & Africa – Algeria, Egypt, Israel, Kuwait, Nigeria, Saudi Arabia, South Africa, Turkey, United Arab Emirates, & Rest of MEA Competitive Landscape Victrex plc., Solvay, corporate.evonik, Celanese Corporation, Gharda Chemicals Ltd., Ensinger, Lehmann&Voss&Co., Prototype & Plastic Mold Company Inc., Caledonian Industries Ltd., Toray Advanced Composites, Jrlon Inc., Tri-Mack Plastics Manufacturing Corporation, RTP Company, The Mitsubishi Chemical Advanced Materials, Arkema, Nanoshel LLC, Panjin Zhongrun Chemical Co. Ltd Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) -

-

- Victrex plc.

- Solvay

- corporate.evonik

- Celanese Corporation

- Gharda Chemicals Ltd.

- Ensinger

- Lehmann&Voss&Co.

- Prototype & Plastic Mold Company Inc.

- Caledonian Industries Ltd.

- Toray Advanced Composites

- Jrlon Inc.

- Tri-Mack Plastics Manufacturing Corporation

- RTP Company

- The Mitsubishi Chemical Advanced Materials

- Arkema

- Nanoshel LLC

- Panjin Zhongrun Chemical Co. Ltd