Laser Marking Machines Market By Type (Fiber Laser, Diode Laser, Solid-state Laser, CO2 Laser, UV Laser, Others), By Machine Type (2D, 3D), By Product Type (Fixed, Portable), By Application (Ablation, Annealing, Carbonizing, Others), By Material (Metal, Glass, Plastics, Others), By End-Use (Machine Tool, Automotive, Electronics & Semiconductor, Defense & Aerospace, Others), By Region And Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, And Forecast 2024-2033

-

50829

-

August 2024

-

300

-

-

This report was compiled by Kalyani Khudsange Kalyani Khudsange is a Research Analyst at Prudour Pvt. Ltd. with 2.5 years of experience in market research and a strong technical background in Chemical Engineering and manufacturing. Correspondence Sr. Research Analyst Linkedin | Detailed Market research Methodology Our methodology involves a mix of primary research, including interviews with leading mental health experts, and secondary research from reputable medical journals and databases. View Detailed Methodology Page

-

Quick Navigation

- Report Overview

- Key Takeaways

- Driving factors

- Restraining Factors

- By Type Analysis

- By Machine Type Analysis

- By Product Type Analysis

- By Application Analysis

- By Material Analysis

- By End-Use Analysis

- Key Market Segments

- Growth Opportunity

- Latest Trends

- Regional Analysis

- Key Players Analysis

- Recent Development

- Report Scope

Report Overview

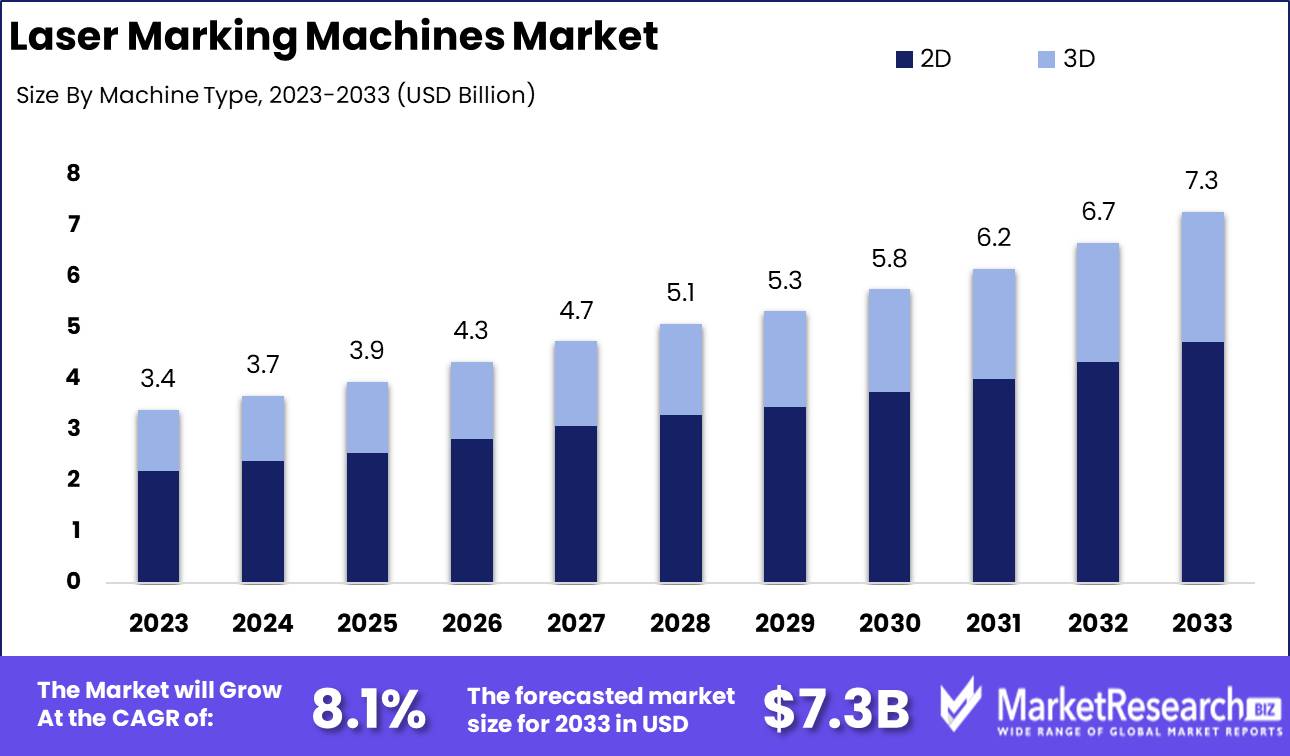

The Laser Marking Machines Market was valued at USD 3.4 billion in 2023. It is expected to reach USD 7.3 billion by 2033, with a CAGR of 8.1% during the forecast period from 2024 to 2033.

The Laser Marking Machines Market encompasses the industry focused on producing, distributing, and innovating laser-based systems used for marking and engraving applications across various sectors. These machines employ laser technology to create precise, permanent marks on materials, ranging from metals to plastics, for traceability, branding, and regulatory compliance.

The global laser marking machines market is poised for significant growth, driven primarily by technological advancements and increasing demand in key sectors such as electronics and automotive. The evolution of laser technologies, including fiber, diode, and CO2 lasers, has enabled more precise and efficient marking processes, enhancing the appeal of these machines across industries. In particular, the electronics sector's demand for high-precision marking on small components and the automotive industry's need for durable, legible markings on various materials have been pivotal in driving market expansion. Furthermore, integrating advanced software solutions has facilitated seamless operations, enabling manufacturers to meet the stringent quality and regulatory requirements in these sectors.

However, the market is not without its challenges. The high initial investment required for laser marking systems poses a barrier for small and medium-sized enterprises, potentially limiting market penetration in this segment. Additionally, the technical complexity associated with operating and maintaining these machines demands skilled personnel, which can further exacerbate operational costs. Despite these challenges, the long-term benefits of laser marking such as lower operational costs, minimal maintenance, and the ability to mark on diverse materials continue to outweigh the initial drawbacks. As technological integration improves and costs gradually decrease, the adoption of laser marking machines is expected to rise steadily, solidifying their position as an essential tool in modern manufacturing.

Key Takeaways

- Market Growth: The Laser Marking Machines Market was valued at USD 3.4 billion in 2023. It is expected to reach USD 7.3 billion by 2033, with a CAGR of 8.1% during the forecast period from 2024 to 2033.

- By Type: Fiber Laser dominated the Laser Marking Machines Market.

- By Machine Type: 2D laser marking machines dominated the market with 65.1%.

- By Product Type: Fixed laser marking machines dominated with 75.8% market share.

- By Application: Ablation dominated with a 35.6% market share in laser marking.

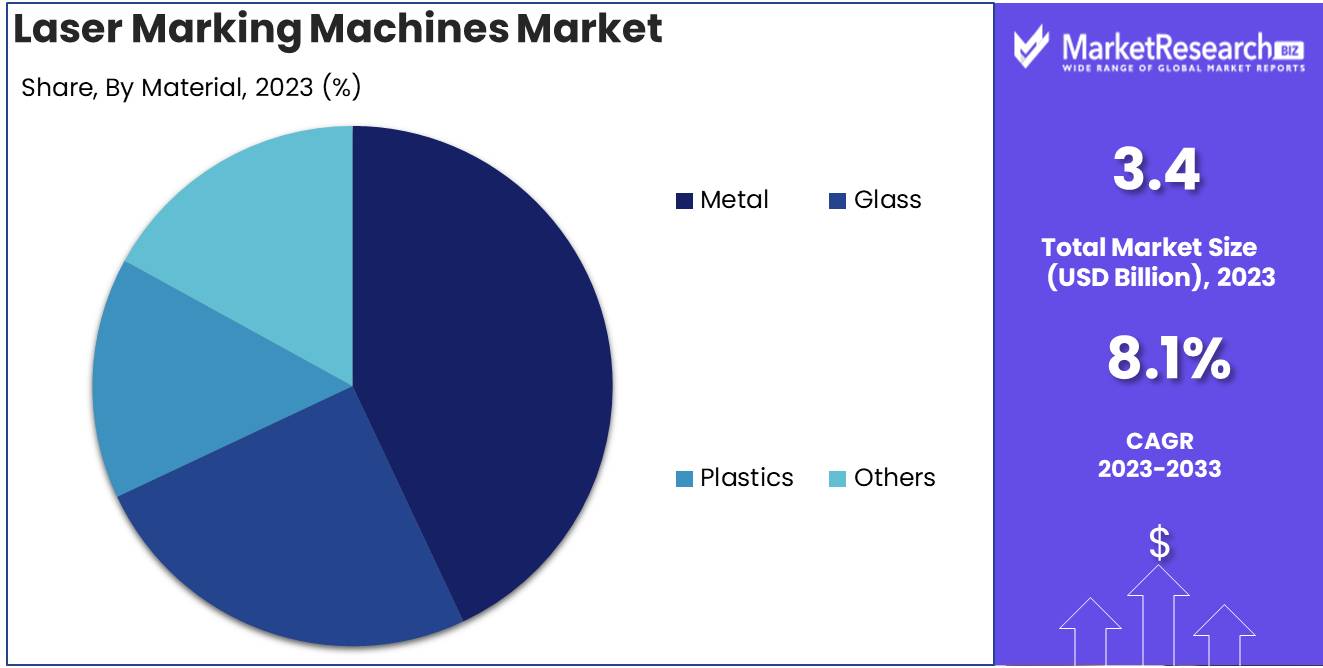

- By Material: Metal dominated the Laser Marking Machines Market by material.

- By End-Use: The Machine Tool segment dominated the Laser Marking Machines Market.

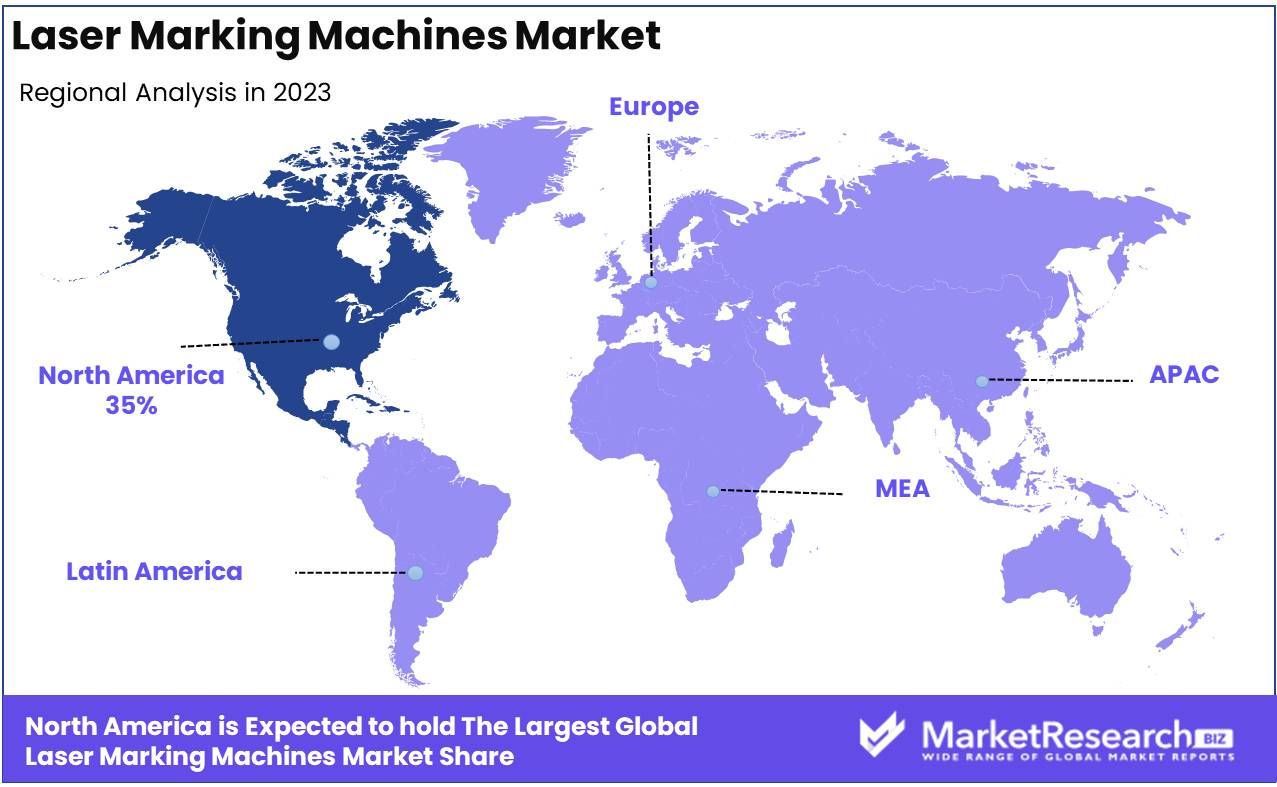

- Regional Dominance: North America dominates the laser marking machines market with a 35% largest share.

- Growth Opportunity: The global laser marking machines market will grow due to expanding industrial applications and increased adoption of software-driven innovations.

Driving factors

Increased Adoption of Laser Technologies

The increased adoption of laser technologies across various industries is a critical driver of growth in the laser marking machines market. Lasers are increasingly preferred for marking due to their ability to provide high precision, durability, and versatility compared to traditional methods. This shift is driven by advancements in laser technology, which have led to improvements in speed, cost-effectiveness, and energy efficiency.

According to industry reports, the global adoption rate of laser technologies in manufacturing processes has seen a significant annual growth rate of approximately 7-10% over the past five years, directly influencing the expansion of the laser marking machines market. The growing utilization of lasers in electronics, automotive, aerospace, and medical industries is expected to further propel market growth as these sectors demand highly precise and permanent marking solutions.

Demand for Traceability and Identification

The increasing demand for traceability and identification is a pivotal factor contributing to the growth of the laser marking machines market. In industries such as automotive, aerospace, and electronics, the need for product traceability has become more pronounced due to stringent regulatory requirements and the growing focus on anti-counterfeiting measures. Laser marking provides a reliable solution for permanent and tamper-proof markings, which are essential for tracking parts throughout the supply chain and ensuring product authenticity. Statistics indicate that the global traceability market is expected to grow at a compound annual growth rate (CAGR) of 12-14% from 2021 to 2028, which in turn is driving the demand for advanced marking solutions like laser marking machines. This trend is particularly strong in the pharmaceutical and food and beverage sectors, where compliance with safety standards and traceability regulations is mandatory.

Expanding Applications Across Key Sectors Fuel Market Expansion

The growth in end-user industries such as automotive, electronics, medical devices, and aerospace significantly contributes to the expansion of the laser marking machines market. These industries increasingly rely on laser marking for its precision, speed, and ability to mark various materials, including metals, plastics, ceramics, and glass. The automotive industry, for instance, uses laser marking for component identification and branding, while the electronics sector employs it for marking circuit boards and microchips.

The medical device industry requires laser marking for traceability of surgical instruments and implants, a necessity driven by strict regulations in healthcare. The combined growth of these industries, which have been expanding at a steady rate of 6-8% annually, has a direct and substantial impact on the demand for laser marking machines. Furthermore, the continuous innovation and development within these sectors, particularly in areas such as electric vehicles and consumer electronics, are expected to sustain and even accelerate market growth in the coming years.

Restraining Factors

Maintenance and Repair Challenges: A Barrier to the Uninterrupted Growth of the Laser Marking Machines Market

Maintenance and repair challenges serve as a significant restraining factor in the growth of the laser marking machines market. Laser marking machines, although efficient and precise, require regular maintenance to ensure consistent performance. The complexity of these machines often necessitates specialized skills for repairs and upkeep, which can be a costly and time-consuming endeavor. This requirement for specialized maintenance contributes to increased operational costs for businesses, particularly for small and medium-sized enterprises (SMEs) that may not have the resources to manage these demands effectively.

Consequently, the financial burden associated with maintenance can deter potential buyers, thereby restraining market growth. The need for regular servicing and potential downtime during repairs can also disrupt production processes, further discouraging adoption and hindering market expansion.

Availability of Alternative Technologies: A Competitive Pressure on Market Expansion

The availability of alternative technologies poses a significant challenge to the growth of the laser marking machines market. Technologies such as inkjet printing, dot peen marking, and chemical etching offer competitive advantages in terms of cost-effectiveness and flexibility. For instance, inkjet printing provides a low-cost solution for marking, particularly for applications where the durability of laser marking is not a primary concern. Dot peen marking, known for its durability and ability to mark on various materials, also serves as a viable alternative, especially in industries where deep marking is required. The chemical etching process, while more environmentally hazardous, offers precision at a lower initial investment. These alternatives, which often have lower upfront and operational costs, can attract businesses looking to minimize expenditures, thereby limiting the market share and growth potential of laser marking machines.

By Type Analysis

In 2023, Fiber Laser dominated the Laser Marking Machines Market.

In 2023, Fiber Laser technology held a dominant market position in the by-type segment of the Laser Marking Machines Market, capturing more than a 39.4% share. The superior efficiency, precision, and versatility of fiber lasers, particularly in industrial applications such as automotive, electronics, and aerospace, contributed significantly to this leadership position.

Diode Laser systems, valued for their compactness and high-speed marking capabilities, followed, holding a substantial share, particularly in the electronics and packaging sectors. Solid-state Laser technology, known for its robustness and adaptability in metal marking and engraving applications, also maintained a significant presence, though it was slightly behind fiber and diode lasers.

CO2 Lasers, predominantly used for organic materials like wood, glass, and leather, captured a notable market share, reflecting their continued relevance in non-metal marking applications. UV Lasers, with their precision in micro-marking and minimal thermal damage, gained traction in the medical and electronics industries, while the Others category, encompassing emerging and specialized laser technologies, accounted for a smaller, yet growing, portion of the market.

By Machine Type Analysis

In 2023, 2D laser marking machines dominated the market with 65.1%.

In 2023, 2D laser marking machines held a dominant market position in the Machine Type segment of the Laser Marking Machines Market, capturing more than a 65.1% share. This dominance can be attributed to the widespread adoption of 2D laser marking technology across various industries, including automotive, electronics, and packaging. The preference for 2D machines is driven by their cost-effectiveness, ease of integration, and suitability for marking flat surfaces with high precision. Additionally, advancements in fiber laser technology have enhanced the efficiency and speed of 2D laser marking systems, further solidifying their market presence.

3D laser marking machines accounted for a smaller but growing portion of the market. These machines are increasingly favored in industries requiring intricate and multi-dimensional markings, such as aerospace and medical devices. The ability of 3D laser marking systems to engrave on curved or irregular surfaces is a key differentiator, driving their adoption in specialized applications. However, the higher cost and complexity of 3D systems have limited their widespread use, compared to 2D systems, which continue to dominate the market.

By Product Type Analysis

In 2023, Fixed laser marking machines dominated with a 75.8% market share.

In 2023, Fixed laser marking machines held a dominant market position in the By Product Type segment of the Laser Marking Machines Market, capturing more than a 75.8% share. The fixed systems, known for their superior precision and stability, have become the preferred choice in industries requiring high accuracy, such as automotive, electronics, and aerospace. Their capability to handle large-scale production with consistent marking quality has been a key driver behind their extensive adoption. Furthermore, the integration of fixed laser marking machines into automated production lines has significantly contributed to their market leadership, particularly in high-volume manufacturing sectors.

Portable laser marking machines, while more versatile and suitable for smaller or more intricate tasks, have captured a smaller market share. Their flexibility and ease of use make them ideal for applications where mobility is critical, such as in the jewelry and medical device industries. However, the dominance of fixed systems in large-scale industrial applications has limited the market penetration of portable machines, despite their growing popularity in niche segments.

By Application Analysis

In 2023, Ablation dominated with a 35.6% market share in laser marking.

In 2023, Ablation held a dominant market position in the "By Application" segment of the Laser Marking Machines Market, capturing more than a 35.6% share. The application of ablation in laser marking is particularly favored for its precision in removing material to create high-definition marks on various substrates, making it essential in industries such as electronics and aerospace.

Annealing, representing a significant segment, is widely used in metal marking, especially stainless steel, where the process modifies the material's surface properties without removing material, contributing to its popularity in the automotive and medical industries.

Carbonizing, though less dominant, has seen increased adoption in plastic and organic material marking due to its ability to create contrasting marks, particularly in consumer goods.

Foaming, a niche yet growing application, is preferred for polymer marking as it produces raised, contrasting marks, ideal for branding and identification purposes.

Engraving, a traditional method, continues to hold relevance, particularly in the jewelry and personalization sectors.

Other applications, including etching and surface modification, collectively account for a smaller market share but are critical for specialized industrial requirements.

By Material Analysis

In 2023, Metal dominated the Laser Marking Machines Market by material.

In 2023, Metal held a dominant market position in the By Material segment of the Laser Marking Machines Market, capturing more than a 42.6% share. The high conductivity, durability, and widespread applicability of metals in various industries such as automotive, aerospace, and electronics have significantly driven the demand for metal laser marking. This segment's robust growth is further propelled by the increasing need for precise and permanent markings, especially for parts tracking and regulatory compliance.

Glass emerged as another critical material segment, driven by its applications in packaging, automotive, and consumer electronics. Laser marking on glass is preferred for its high precision and non-contact process, ensuring no material degradation.

Plastics followed closely, capturing a substantial market share due to their extensive use in consumer goods, medical devices, and automotive components. The ability to achieve high-contrast markings without altering the plastic's physical properties has made laser marking an ideal choice.

The Others segment, encompassing ceramics, wood, and composites, also exhibited steady growth, catering to niche applications requiring customized solutions. The versatility of laser marking across these materials underscores the growing importance of this technology across various industries.

By End-Use Analysis

In 2023, The Machine Tool segment dominated the Laser Marking Machines Market.

In 2023, The Machine Tool segment held a dominant market position in the Laser Marking Machines Market, capturing more than 26.8% share by end-use. This segment's leadership can be attributed to the widespread adoption of laser marking technology in machining processes for its precision and efficiency in marking intricate designs on metal and other hard surfaces. Automotive followed closely, driven by the increasing demand for permanent marking solutions to meet regulatory standards for traceability and identification of components. The Electronics & Semiconductor segment also represented a significant share, fueled by the sector’s need for micro-marking and high-precision engraving.

In the Defense & Aerospace sector, laser marking has been crucial for the permanent marking of high-value parts, ensuring durability under extreme conditions. Healthcare leveraged laser marking for the traceability and identification of medical devices, contributing to its growing share. Packaging & Labeling saw substantial usage due to the need for high-speed, high-quality marking. Lastly, the Others segment, encompassing various niche industries, contributed to the overall market share with diverse applications of laser marking technology.

Key Market Segments

By Type

- Fiber Laser

- Diode Laser

- Solid-state Laser

- CO2 Laser

- UV Laser

- Others

By Machine Type

- 2D

- 3D

By Product Type

- Fixed

- Portable

By Application

- Ablation

- Annealing

- Carbonizing

- Foaming

- Engraving

- Others

By Material

- Metal

- Glass

- Plastics

- Others

By End-Use

- Machine Tool

- Automotive

- Electronics & Semiconductor

- Defense & Aerospace

- Healthcare

- Packaging & Labeling

- Others

Growth Opportunity

Expanding Usage in Different Industries

The global laser marking machines market is poised for significant growth, driven by the expanding usage across various industries. The demand for high-precision marking and engraving solutions has surged, particularly in sectors such as automotive, aerospace, electronics, and healthcare. In the automotive industry, laser marking is increasingly utilized for part identification, traceability, and anti-counterfeiting measures, ensuring compliance with stringent regulations.

Similarly, in the electronics sector, the miniaturization of components necessitates precise and permanent markings, which laser technology delivers efficiently. The healthcare industry, with its rigorous requirements for product traceability and sterilization, has also adopted laser marking for medical devices and surgical instruments. This broadening application spectrum underscores the versatility of laser marking technology, positioning the market for robust expansion.

Penetration of Software-based Solutions

The integration of software-based solutions represents another significant growth opportunity. As Industry 4.0 continues to evolve, the demand for advanced software that enhances the functionality and efficiency of laser marking machines is increasing. Software solutions enable the automation of marking processes, real-time monitoring, and customization, which are crucial for meeting the specific needs of various industries.

Additionally, the adoption of cloud-based platforms and IoT-enabled devices is expected to drive further innovation in laser marking systems, allowing for seamless integration into existing manufacturing workflows. This penetration of software-based solutions not only enhances operational efficiency but also provides manufacturers with a competitive edge, further propelling the market’s growth in the coming year.

Latest Trends

Increasing Demand for Laser Marking Services

The laser marking machines market is expected to witness significant growth, driven primarily by the increasing demand for laser marking services. This trend is being fueled by the rising need for precise and durable marking solutions across various industries, including automotive, electronics, and medical devices. Laser marking services are becoming more popular due to their ability to provide high-quality, permanent markings without the need for consumables such as inks or dyes. The versatility and precision offered by laser marking systems make them ideal for applications requiring fine detail, such as serial numbers, barcodes, and logos. As industries increasingly adopt traceability practices to comply with regulatory standards and improve product safety, the demand for these services is likely to expand further.

3D Laser Marking

The advent of 3D laser marking technology represents a transformative trend in the market, poised to revolutionize the way manufacturers approach product identification and branding. Unlike traditional 2D laser marking, 3D laser marking enables the engraving of complex shapes and surfaces, including curved and uneven surfaces, with exceptional precision. This capability opens new opportunities in industries such as aerospace, automotive, and consumer electronics, where components often feature intricate designs and require high-precision markings. The growing interest in customization and personalization of products further bolsters the adoption of 3D laser marking technology, positioning it as a key driver of market growth.

Regional Analysis

North America dominates the laser marking machines market with a 35% largest share.

The global laser marking machines market demonstrates significant regional variations, with North America leading as the dominant region. North America's market share accounts for approximately 35% of the global market, driven by the robust presence of key industries such as aerospace, automotive, and electronics, which demand high-precision marking solutions. The region’s advanced manufacturing infrastructure and the adoption of cutting-edge technologies further bolster market growth.

Europe follows, contributing around 28% to the global market share. The region's focus on innovation, particularly in Germany and Italy, is a critical driver, with industries like automotive and medical devices heavily utilizing laser marking for traceability and product identification.

The Asia Pacific region is projected to witness the fastest growth, with a CAGR of over 8% during the forecast period. The rise in manufacturing activities in China, Japan, and South Korea, coupled with increasing investments in automation, contributes significantly to this growth.

The Middle East & Africa and Latin America regions collectively hold a smaller share, approximately 9%, but are expected to see gradual growth due to emerging industrial sectors and increasing adoption of advanced manufacturing technologies. North America's dominance is expected to continue due to its technological advancements and strong industrial base.

Key Regions and Countries

North America

- The US

- Canada

- Rest of North America

Europe

- Germany

- France

- The UK

- Spain

- Netherlands

- Russia

- Italy

- Rest of Europe

Asia-Pacific

- China

- Japan

- Singapore

- Thailand

- South Korea

- Vietnam

- India

- New Zealand

- Rest of Asia Pacific

Latin America

- Mexico

- Brazil

- Rest of Latin America

Middle East & Africa

- Saudi Arabia

- South Africa

- UAE

- Rest of the Middle East & Africa

Key Players Analysis

The global Laser Marking Machines Market is anticipated to exhibit robust growth, driven by technological advancements, increased automation across industries, and rising demand for precision marking solutions. Key players within this market are expected to capitalize on these trends by leveraging their established technological expertise and expanding their product portfolios.

Danaher Corporation and IPG Photonics Corporation are poised to maintain their leadership positions through continuous innovation and integration of advanced laser technologies. Their extensive R&D capabilities and strong global presence will likely allow them to cater to the growing demand for high-performance laser marking systems across diverse sectors.

Trumpf GmbH + Co. KG and Keyence Corporation are anticipated to focus on enhancing their product offerings by incorporating Industry 4.0 technologies, such as IoT and AI, into their laser marking solutions. This strategic move is expected to strengthen its market position by providing customers with more efficient and intelligent marking solutions.

Novanta Inc. and Gravotech Marking SAS are expected to capitalize on niche markets by offering specialized laser marking solutions tailored to specific industries, such as healthcare and aerospace. Their ability to provide customized and high-precision marking systems will likely drive their growth in these sectors.

Smaller players like TYKMA Electrox, Inc. and MECCO, LLC may focus on expanding their regional presence and offering competitive pricing strategies to capture market share. Additionally, partnerships and collaborations with local distributors could enhance their market penetration.

Overall, the competitive landscape of the laser marking machines market will be characterized by innovation, technological integration, and strategic collaborations aimed at addressing the evolving needs of various industries.

Market Key Players

- Danaher Corporation

- IPG Photonics Corporation

- Trumpf GmbH + Co. KG

- Keyence Corporation

- Novanta Inc.

- Gravotech Marking SAS

- Trotec Laser GmbH

- LaserStar Technologies Corporation

- TYKMA Electrox, Inc.

- Telesis Technologies, Inc.

- Epilog Laser, LLC

- MECCO, LLC

- Huagong Tech Co., Ltd.

- The 600 Group PLC

- Videojet Technologies, Inc.

Recent Development

- In June 2024, Coherent Corp. announced a strategic partnership with GE Healthcare to develop advanced laser marking solutions tailored for medical devices. This collaboration aims to create marking systems that comply with stringent medical industry regulations, ensuring permanent, high-contrast marks on a variety of medical-grade materials. The partnership reflects the growing demand for traceability and identification in the healthcare sector.

- In May 2024, TRUMPF Group introduced the TruMark 5000 series, a new generation of laser marking machines. This series is designed to offer higher precision and speed, particularly for applications in the automotive and electronics industries. The TruMark 5000 series features improved cooling systems and enhanced software integration, enabling more complex marking tasks with greater efficiency.

- In March 2024, Keyence Corporation announced the expansion of its laser marking division with the opening of a new manufacturing facility in Yokohama, Japan. The facility is dedicated to the production of the latest fiber laser marking machines, addressing the increased global demand. This expansion is part of Keyence's broader strategy to enhance its market share in Europe and North America.

Report Scope

Report Features Description Market Value (2023) USD 3.4 Billion Forecast Revenue (2033) USD 7.3 Billion CAGR (2024-2032) 8.1% Base Year for Estimation 2023 Historic Period 2016-2023 Forecast Period 2024-2033 Report Coverage Revenue Forecast, Market Dynamics, COVID-19 Impact, Competitive Landscape, Recent Developments Segments Covered By Type (Fiber Laser, Diode Laser, Solid-state Laser, CO2 Laser, UV Laser, Others), By Machine Type (2D, 3D), By Product Type (Fixed, Portable), By Application (Ablation, Annealing, Carbonizing, Others), By Material (Metal, Glass, Plastics, Others), By End-Use (Machine Tool, Automotive, Electronics & Semiconductor, Defense & Aerospace, Others) Regional Analysis North America - The US, Canada, Rest of North America, Europe - Germany, France, The UK, Spain, Italy, Russia, Netherlands, Rest of Europe, Asia-Pacific - China, Japan, South Korea, India, New Zealand, Singapore, Thailand, Vietnam, Rest of Asia Pacific, Latin America - Brazil, Mexico, Rest of Latin America, Middle East & Africa - South Africa, Saudi Arabia, UAE, Rest of Middle East & Africa Competitive Landscape Danaher Corporation, IPG Photonics Corporation, Trumpf GmbH + Co. KG, Keyence Corporation, Novanta Inc., Gravotech Marking SAS, Trotec Laser GmbH, LaserStar Technologies Corporation, TYKMA Electrox, Inc., Telesis Technologies, Inc., Epilog Laser, LLC, MECCO, LLC, Huagong Tech Co., Ltd., The 600 Group PLC, Videojet Technologies, Inc. Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) -

-

- Danaher Corporation

- IPG Photonics Corporation

- Trumpf GmbH + Co. KG

- Keyence Corporation

- Novanta Inc.

- Gravotech Marking SAS

- Trotec Laser GmbH

- LaserStar Technologies Corporation

- TYKMA Electrox, Inc.

- Telesis Technologies, Inc.

- Epilog Laser, LLC

- MECCO, LLC

- Huagong Tech Co., Ltd.

- The 600 Group PLC

- Videojet Technologies, Inc.