Industrial Tapes Market Product Type(Filament Tapes, Aluminum Tapes, Duct Tapes, Others), Application(Manufacturing Industry, Automotive Industry, Logistics Industry), Backing Material(Polypropylene, Paper, Polyvinyl Chloride), Mode of Application(Masking, Conducting, Packaging Design), By Region And Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, And Forecast 2024-2033

-

10331

-

May 2023

-

188

-

-

This report was compiled by Correspondence Linkedin | Detailed Market research Methodology Our methodology involves a mix of primary research, including interviews with leading mental health experts, and secondary research from reputable medical journals and databases. View Detailed Methodology Page

-

Industrial Tapes Market Size, Share, Trends Analysis

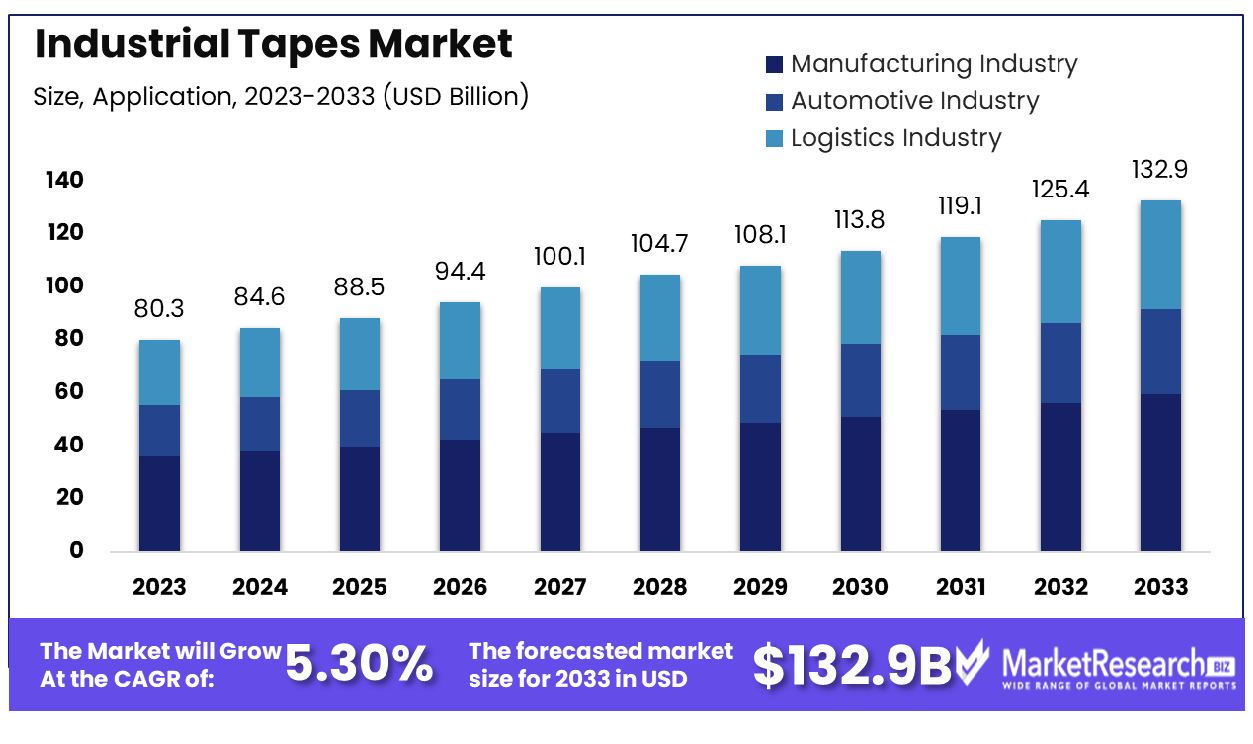

The industrial tapes market was valued at USD 80.3 billion in 2023. It is expected to reach USD 132.9 billion by 2033, with a CAGR of 5.30% during the forecast period from 2024 to 2033.

The surge in demand in various sectors and government policies are some of the main driving factors for the industrial tapes market expansion. Industrial tapes are widely used for industrial applications. These industrial adhesive tapes are widely used to cover manufacturing production holes and attachments.

These exceptional features enable them to be an ideal choice for different sectors. These are made up of copper, lead, plastic, and metal foil. Several types are accessible at CGS tapes, which are stretchable, translucent, and can hold pressure. These are biodegradable, UV and moisture-resistant.

Industrial tapes are also used in a wide range of industries to bond elements, join materials, and provide great cohesion. Due to its high-end performance industrial tapes are available in each market to offer industrial products. In the automotive industry, these industrial tapes are commonly used as the automotive industry is quite vast and so are the production requirements. It is roughly estimated that 800,000 to 900,000 square meters are full of industrial adhesive tapes that can be used to help this industry.

Adhesive tapes are used every day to make sure and gather the 2 to 5 Km cables that are required to run inside a new vehicle, up to 50 adhesive tapes are used in one new vehicle. These are commonly used to protect different components in the production process. The automotive industry also requires the usage of industrial tape to hold the screws and studs so that the car seats and dashboards can easily get stuck in one place.

In the packaging industry, industrial tapes play a major role. The main function of these types is to safeguard and seal the packages by protecting the intact contents from external components during the transmission, storage, and handling process. Industrial tapes ensure that the products reach their desired designation in good condition. Various types of industrial tapes are designed for different functionality in the packaging.

Pressure-sensitive adhesive tapes are ideal for quick applications while water-activated tapes can provide reliable seals when handling heavy packaging materials. Packaging key companies can customize solutions based on each product's unique packaging needs using different kinds of tapes; therefore, demand will only continue to increase in coming years due to increasing usage across industries and thus contributing to market expansion.

Industrial Tapes Market Dynamics

Diverse Industrial Applications Propel Market Growth

The industrial tapes market is experiencing robust growth driven by its extensive applications across various industries, including automotive, packaging, medical, and construction. These tapes offer specific functionalities such as bonding, sealing, and insulating, meeting diverse industry needs.

As sectors like automotive and construction continue to innovate and expand, the demand for specialized industrial tapes that contribute to efficiency, safety, and durability is expected to rise, further propelling market growth. The industrial tapes market relies on double-sided tape for strong and reliable bonding in various manufacturing applications.

Globalization and Industrialization Fuel Demand

The increasing globalization of businesses and rapid industrialization in developing countries are significant drivers of the industrial tapes market. As companies expand their operations globally, the need for robust, efficient packaging and manufacturing solutions, including industrial tapes, grows.

Industrial tapes play a crucial role in ensuring product safety and efficiency during transportation and handling. Emerging economies' continued industrial expansion should propel demand for these tapes and result in market expansion.

Eco-Friendly Demand Shapes Market Trends

The growing demand for environmentally friendly products is shaping the industrial tapes market. Companies are increasingly seeking tapes that are not only efficient and safe but also minimize environmental impact. Industrial tapes that save time, money, and resources while reducing waste and emissions are particularly appealing.

As sustainability becomes a priority for businesses and regulators, the market for eco-friendly industrial tapes is expected to expand, with innovations focusing on biodegradability and recyclability driving future growth.

Availability of Alternative Bonding Solutions Limits Industrial Tapes Market Adoption

The availability of alternative bonding solutions like mechanical fasteners and liquid adhesives can limit the adoption of industrial tapes in certain applications. While industrial tapes offer advantages like ease of use and clean application, some industries might prefer traditional bonding methods for their perceived durability or cost-effectiveness.

In scenarios requiring extreme strength or where the bonding material is exposed to harsh conditions, alternatives might be favored over tapes. Due to this trend, industrial tapes are unlikely to experience growth as applications-specific solutions tend to be preferred over industrial tapes.

Stringent Regulations Impact Industrial Tapes Market in Certain Regions

Stringent regulations on the use of certain chemicals used in industrial tape production could impede their adoption in some regions. Environmental and health concerns have led to regulations restricting the use of volatile organic compounds (VOCs) and other hazardous materials in manufacturing processes.

Compliance with these regulations can increase production costs and complexity. In regions with particularly strict standards, this can hinder the marketability of certain industrial tapes, pushing manufacturers to reformulate products or potentially lose market share to compliant alternatives.

Industrial Tapes Market Segmentation Analysis

Product Type Analysis

In the industrial tapes market, Filament Tapes are recognized as the dominant segment. Their strength and durability, coupled with the ability to withstand high tension and environmental conditions, make them a preferred choice in various industrial applications. Filament tapes are extensively used for heavy-duty packaging, bundling, and reinforcement tasks, especially in sectors that require robust holding power and long-term stability.

While filament tapes lead due to their versatility and strength, other types such as Aluminum Tapes, Duct Tapes, and Adhesive Transfer Tapes also play significant roles. Aluminum tapes are sought after for their thermal and electrical conductivity properties, duct tapes for their wide range of uses in repair and maintenance, and adhesive transfer tapes for their clean application and strong adhesive properties.

Application Analysis

The Manufacturing Industry emerges as the dominant application segment for industrial tapes. The diverse needs of manufacturing, from assembly to packaging and maintenance, require a variety of tapes with specific properties. In this sector, tapes are not just used for binding but also tasks like thermal management, electrical insulation, and labeling.

The Automotive Industry and Logistics Industries also substantially use industrial tapes. Automotive manufacturers utilize specialized tapes for assembly, wiring, and thermal management, while the logistics industry relies on tapes for secure and efficient packaging solutions.

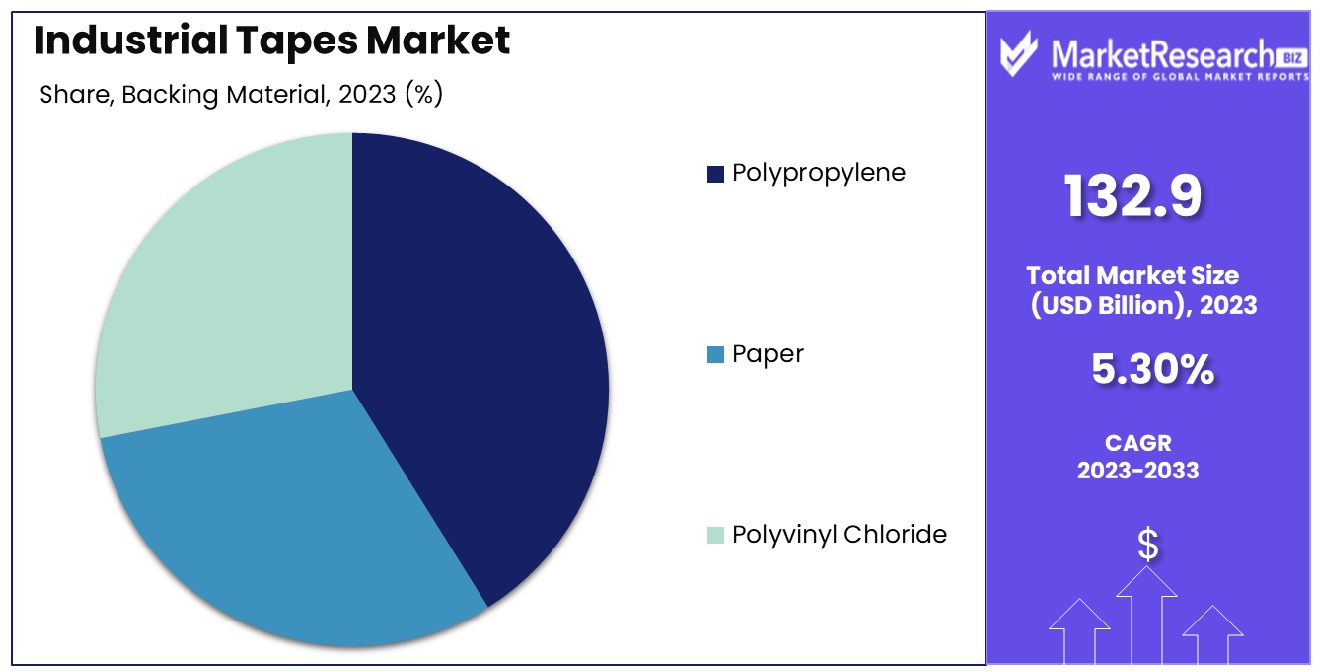

Backing Material Analysis

Polypropylene is the leading backing material in the industrial tapes market. Its popularity is attributed to its balance of flexibility, strength, and resistance to moisture and chemicals, making it suitable for a wide range of industrial applications. Polypropylene tapes are frequently employed for packaging, bundling, and labeling applications where their strength and resistance to damage are crucial.

Paper and Polyvinyl Chloride (PVC) are also important backing materials, each offering unique properties. Paper tapes are widely favored due to their eco-friendliness and easy application in applications like painting and surface protection, while PVC tapes offer electrical insulation properties as well as longevity.

Mode of Application Analysis

Masking, Conducting, and Packaging Design are key modes of application for industrial tapes. Masking tapes are extensively used in painting and surface protection during manufacturing and construction processes. Conducting tapes, typically made from materials like aluminum, are essential for electromagnetic shielding and heat dissipation. Packaging design uses a variety of tapes to secure and brand packages, playing a crucial role in logistics and product presentation.

Industrial Tapes Industry Segments

Product Type

- Filament Tapes

- Aluminum Tapes

- Duct Tapes

- Adhesive Transfer Tapes

- Others

Application

- Manufacturing Industry

- Automotive Industry

- Logistics Industry

Backing Material

Mode of Application

- Masking

- Conducting

- Packaging Design

Industrial Tapes Market Growth Opportunity

Versatility Across Industries Spurs Growth in Industrial Tapes Market

The industrial tapes market's service to several industries, including automotive, aerospace, construction, and manufacturing, presents significant growth opportunities. As these sectors expand and transform, their needs for tapes that meet specific industrial specifications increase.

Industrial tapes are used for various applications, from bonding and sealing to insulation and packaging. The diversity of applications across multiple industries underlines a broad market potential, as each sector's growth can contribute to an increased demand for industrial tapes, driven by the continuous need for reliable and efficient bonding solutions.

Technological Advancements Drive Innovation in the Industrial Tapes Market

Ongoing technological advancements are leading to the development of innovative industrial tape products, creating growth opportunities in the market. Manufacturers are continually improving tape materials, adhesives, and production processes to offer stronger, more versatile, and application-specific tapes.

Innovations such as enhanced adhesive formulations and eco-friendly materials meet the changing demands of industries looking for more efficient and sustainable solutions. The commitment to innovation and product development is key to expanding the market, as new and improved tapes can address a wider range of industrial challenges.

Industrial Tapes Market Regional Analysis

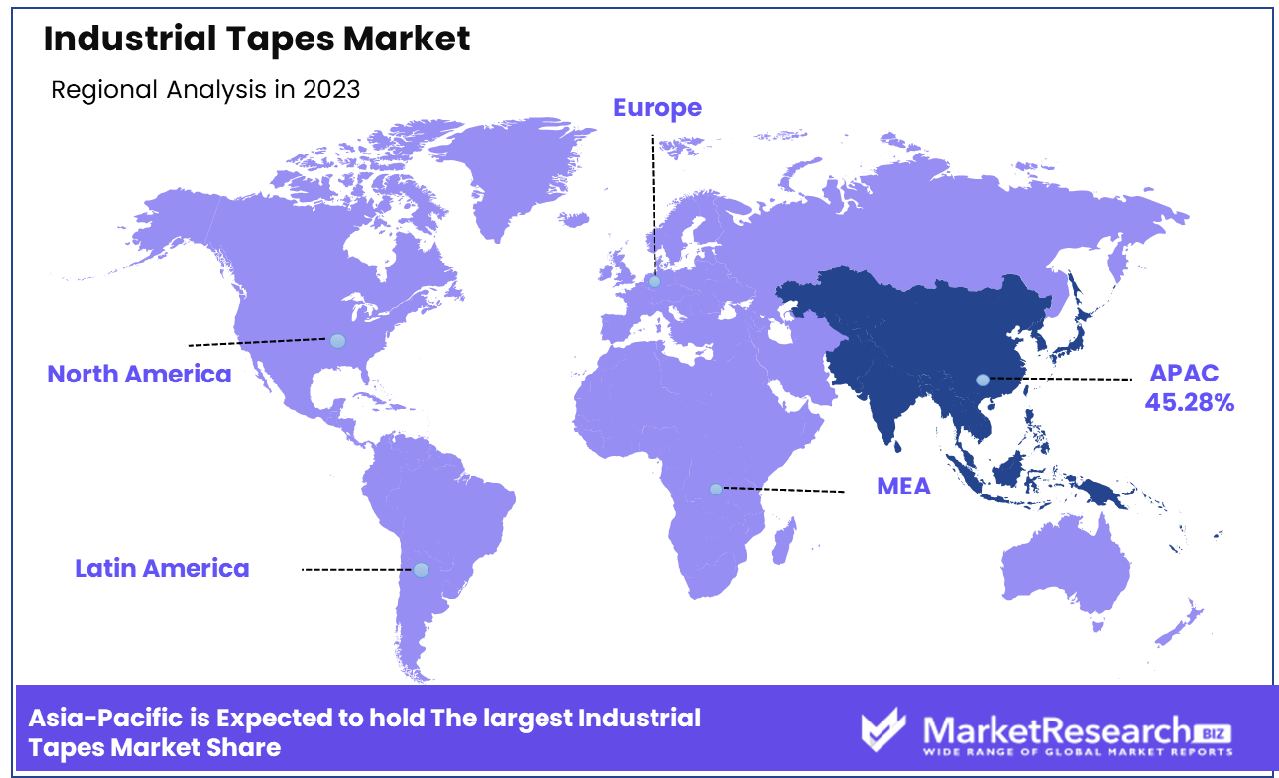

Asia-Pacific Dominates with 45.28% Market Share in Industrial Tapes Market

Asia-Pacific's commanding 45.28% share of the industrial tapes market is primarily driven by the region's expansive manufacturing sector and rapid industrialization, particularly in China, India, and Japan. Growing production activities across automotive, electronics, and construction industries contribute significantly to an increasing need for industrial tapes.

Furthermore, export-oriented growth in this region combined with cost-effective labor and raw materials drives market expansion. Furthermore, urbanization key trends and industrial improvements further increase this need. Tapes used for bonding, sealing, assembly, or sealing operations often serve this function best.

Asia-Pacific region markets are driven by innovation in tape technologies, particularly for specific industrial uses. The increasing emphasis on sustainable manufacturing practices and the demand for eco-friendly adhesives are also shaping the market. Additionally, the growing small and medium-sized enterprises (SMEs) in the region and the expanding infrastructure development projects require high-performance industrial tapes, driving market growth.

North America: Advanced Manufacturing and Technological Leadership

North America’s industrial tapes market is driven by advanced manufacturing sectors and technological leadership, particularly in the United States. The region's emphasis on quality and durability, along with the presence of major tape manufacturers, contributes to market growth. Aerospace, automotive, and electronics industries where precision and performance are of utmost importance favor using industrial tapes with specialized properties.

Europe: Focus on Quality and Sustainability

Europe's industrial tapes market stands out for its strong commitment to quality and sustainability. Europe's stringent environmental regulations and push for green manufacturing drive demand for eco-friendly tapes that deliver on performance. Automotive, construction, and renewable energy sectors present ample opportunities for industrial tape growth within Europe's market, as does product innovation; maintaining high industrial standards should continue driving market expansion across the continent.

Industrial Tapes Industry By Region

North America

- The US

- Canada

- Rest of North America

Europe

- Germany

- France

- The UK

- Spain

- Italy

- Russia

- Netherlands

- Rest of Europe

Asia-Pacific

- China

- Japan

- South Korea

- India

- New Zealand

- Singapore

- Thailand

- Vietnam

- Rest of Asia Pacific

Latin America

- Brazil

- Mexico

- Rest of Latin America

Middle East & Africa

- South Africa

- Saudi Arabia

- UAE

- Rest of Middle East & Africa

Industrial Tapes Market Share Analysis

In the industrial tapes market, companies such as 3M, Avery Dennison Corporation, Tesa SE, and Nitto Denko Corporation are at the forefront, significantly influencing the market with their wide range of products and strong global presence. 3M, known for its innovation, offers a diverse portfolio of tapes catering to various industrial needs, reinforcing its position as a market leader.

Avery Dennison and Tesa SE are also prominent, known for their specialized adhesive solutions and commitment to sustainability, which resonate well with current market demands. Nitto Denko stands out with its high-performance tapes used in numerous sectors, driving its strategic positioning.

Companies like Intertape Polymer Group, Shape Technologies, and Scapa Group further enrich the market with their unique product offerings and strategic acquisitions, enhancing their market reach and portfolio diversity. Lintec Corporation and Berry Global focus on technological advancements and expanding their product lines to meet the evolving needs of industries.

Industrial Tapes Industry Key Players

- 3M Company (US)

- Avery Dennison Corporation (US)

- Tesa SE (Germany)

- Nitto Denko Corporation (Japan)

- Intertape Polymer Group Inc. (US)

- Shape Technologies, LLC (US)

- Scapa Group plc (UK)

- Lintec Corporation (Japan)

- Berry Global, Inc. (US)

- Saint-Gobain S.A. (France)

- Dow (US)

- Henkel AG (Germany)

- Eastman Chemical Company or its subsidiaries (US)

- Ashland Inc. (US)

- H.B. Fuller Company (US)

- Microseal Industries Inc.

- Necal Corporation

Industrial Tapes Market Recent Development

- In April 2023, Thermo Fisher Scientific Inc. introduced two novel wet chemistry analyzers, providing fully automated testing in compliance with the U.S. Environmental Protection Agency (EPA) standards. These systems cater to environmental, agricultural, and industrial testing laboratories with precise and streamlined analytical capabilities.

- In December 2022, ABB launched a Sensi+ analyzer, revolutionizing natural gas quality monitoring. This single device detects H2S, H2O, and CO2 contaminants, enhancing pipeline safety, efficiency, and cost-effectiveness with real-time analysis, swift upset responses, and reduced emissions.

- In November 2022, Mettler Toledo introduced the latest iteration of Easy Vis, a compact solution for analyzing liquid samples. This device evaluates optical spectrum, color, and water characteristics, combining functionalities of a colorimeter, spectrophotometer, and water testing methods within a single, portable unit, replacing the need for three separate instruments.

Report Scope

Report Features Description Market Value (2023) USD 80.3 Billion Forecast Revenue (2033) USD 132.9 Billion CAGR (2024-2032) 5.30% Base Year for Estimation 2023 Historic Period 2016-2023 Forecast Period 2024-2033 Report Coverage Revenue Forecast, Market Dynamics, COVID-19 Impact, Competitive Landscape, Recent Developments Segments Covered Product Type(Filament Tapes, Aluminum Tapes, Duct Tapes, Adhesive Transfer Tapes, Others), Application(Manufacturing Industry, Automotive Industry, Logistics Industry), Backing Material(Polypropylene, Paper, Polyvinyl Chloride), Mode of Application(Masking, Conducting, Packaging Design) Regional Analysis North America - The US, Canada, Rest of North America, Europe - Germany, France, The UK, Spain, Italy, Russia, Netherlands, Rest of Europe, Asia-Pacific - China, Japan, South Korea, India, New Zealand, Singapore, Thailand, Vietnam, Rest of Asia Pacific, Latin America - Brazil, Mexico, Rest of Latin America, Middle East & Africa - South Africa, Saudi Arabia, UAE, Rest of Middle East & Africa Competitive Landscape 3M Company (US), Avery Dennison Corporation (US), Tesa SE (Germany), Nitto Denko Corporation (Japan), Intertape Polymer Group Inc. (US), Shape Technologies, LLC (US), Scapa Group plc (UK), Lintec Corporation (Japan), Berry Global, Inc. (US), Saint-Gobain S.A. (France), Dow (US), Henkel AG (Germany), Eastman Chemical Company or its subsidiaries (US), Ashland Inc. (US), H.B. Fuller Company (US), Microseal Industries Inc., Necal Corporation Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) -

-

- 3M Company (US)

- Avery Dennison Corporation (US)

- Tesa SE (Germany)

- Nitto Denko Corporation (Japan)

- Intertape Polymer Group Inc. (US)

- Shape Technologies, LLC (US)

- Scapa Group plc (UK)

- Lintec Corporation (Japan)

- Berry Global, Inc. (US)

- Saint-Gobain S.A. (France)

- Dow (US)

- Henkel AG (Germany)

- Eastman Chemical Company or its subsidiaries (US)

- Ashland Inc. (US)

- H.B. Fuller Company (US)

- Microseal Industries Inc.

- Necal Corporation