Induction Sealing Machines Market By Type (Manual Type, Semi-automotive Type, Automatic Type, Others), By Application (Food & Beverages, Pharmaceuticals, Consumer Goods, Others), By Region and Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 2024-2033

-

48551

-

July 2024

-

136

-

-

This report was compiled by Kalyani Khudsange Kalyani Khudsange is a Research Analyst at Prudour Pvt. Ltd. with 2.5 years of experience in market research and a strong technical background in Chemical Engineering and manufacturing. Correspondence Sr. Research Analyst Linkedin | Detailed Market research Methodology Our methodology involves a mix of primary research, including interviews with leading mental health experts, and secondary research from reputable medical journals and databases. View Detailed Methodology Page

-

Quick Navigation

Report Overview

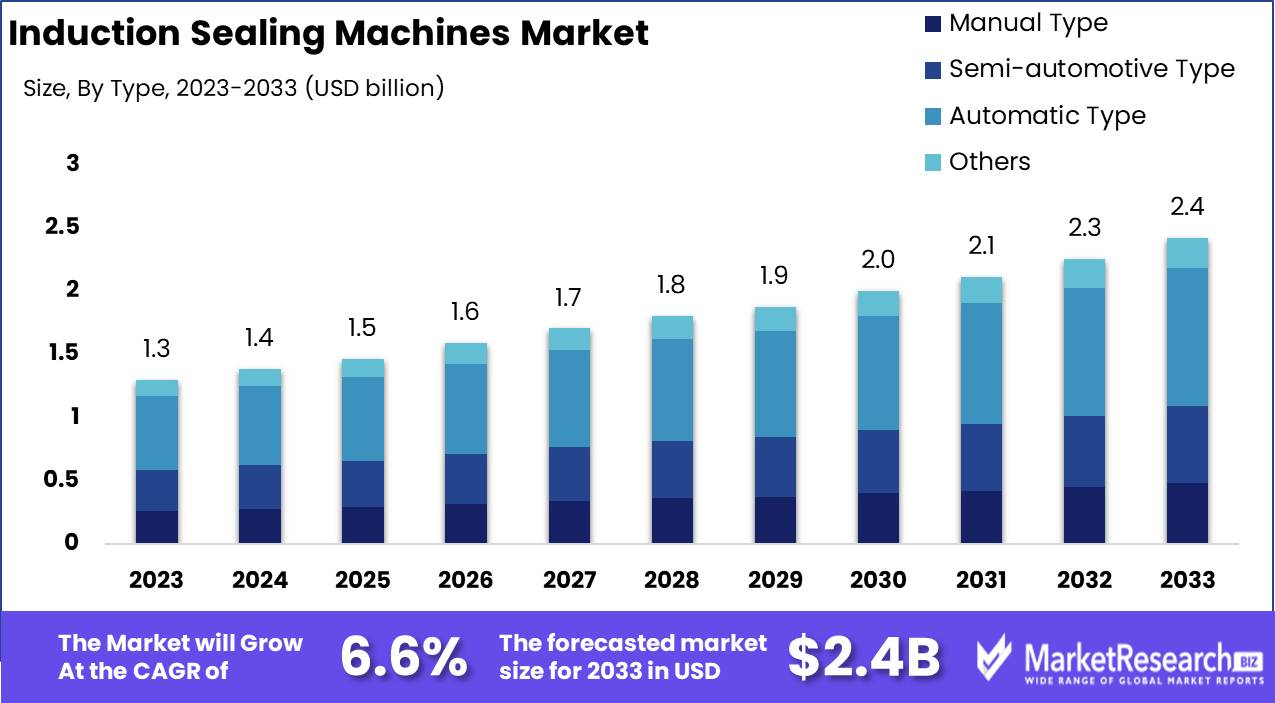

The Global Induction Sealing Machines Market was valued at USD 1.3 Bn in 2023. It is expected to reach USD 2.4 Bn by 2033, with a CAGR of 6.6% during the forecast period from 2024 to 2033.

The Induction Sealing Machines Market encompasses the production, distribution, and application of equipment designed to seal containers using electromagnetic induction. This process involves the generation of an electromagnetic field to heat a metal foil liner, creating a hermetic seal that ensures product integrity, prevents leakage, and extends shelf life. Induction sealing machines are widely used across industries such as food and beverage, pharmaceuticals, chemicals, and cosmetics.

The Induction Sealing Machines Market is experiencing substantial growth, driven by technological advancements and increasing demand for secure, tamper-evident packaging solutions. Invented by Jack Palmer, a process engineer at FR Corporation in the Bronx, NY, in the late 1950s, induction sealing technology has significantly evolved, becoming a critical component in packaging across multiple industries. Today, induction sealing machines are pivotal in ensuring product integrity, preventing leakage, and extending shelf life, particularly in the food and beverage, pharmaceutical, chemical, and cosmetics sectors.

The Induction Sealing Machines Market is experiencing substantial growth, driven by technological advancements and increasing demand for secure, tamper-evident packaging solutions. Invented by Jack Palmer, a process engineer at FR Corporation in the Bronx, NY, in the late 1950s, induction sealing technology has significantly evolved, becoming a critical component in packaging across multiple industries. Today, induction sealing machines are pivotal in ensuring product integrity, preventing leakage, and extending shelf life, particularly in the food and beverage, pharmaceutical, chemical, and cosmetics sectors.A key advantage of induction sealing is its sustainability, particularly through the use of aluminum foil, which is infinitely recyclable and reduces energy consumption by 95% compared to newly mined aluminum. This environmental benefit aligns with the growing consumer and regulatory emphasis on sustainability, driving further adoption of induction sealing technology.

The market's growth is further fueled by the stringent regulatory standards for product safety and quality, compelling manufacturers to invest in reliable sealing solutions. Advancements in induction sealing technology have enhanced operational efficiency and seal integrity, making these machines indispensable in high-speed production environments.

The increasing demand for tamper-evident packaging, driven by consumer safety concerns and regulatory requirements, underscores the critical role of induction sealing machines. These machines provide a robust solution for creating airtight seals that are both secure and easy to verify, ensuring consumer confidence and compliance with industry standards.

Key Takeaways

- Market Value: The Global Induction Sealing Machines Market was valued at USD 1.3 Bn in 2023. It is expected to reach USD 2.4 Bn by 2033, with a CAGR of 6.6% during the forecast period from 2024 to 2033.

- By Type: Automatic type induction sealing machines hold a 45% market share, highlighting their efficiency and widespread adoption.

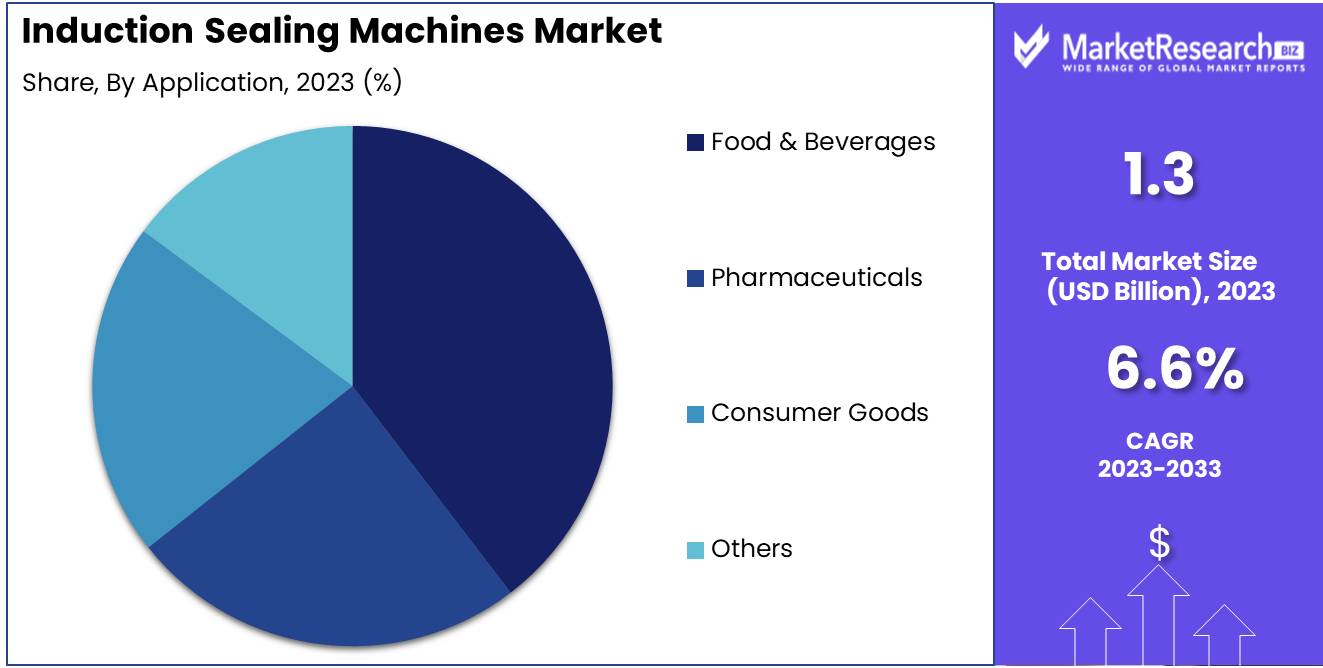

- By Application: The food and beverages industry, requiring high-quality sealing solutions, accounts for 40% of the market.

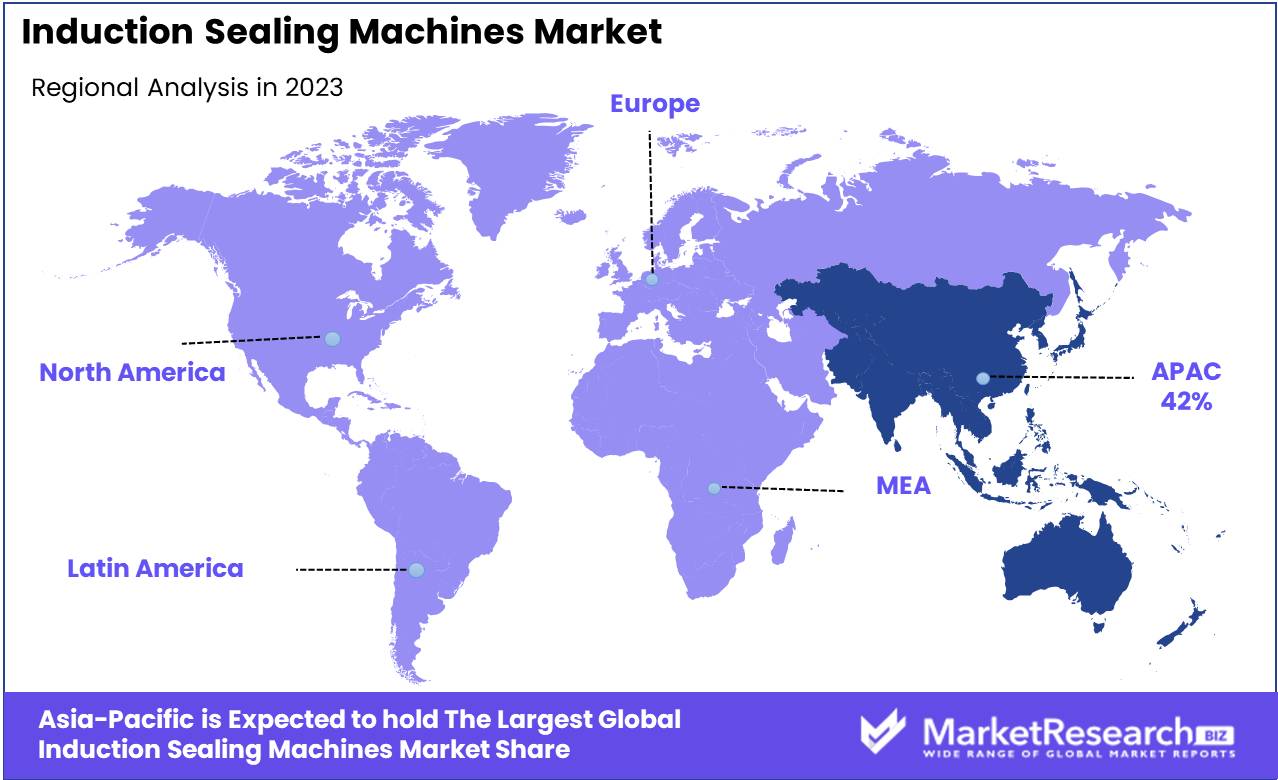

- Regional Dominance: The Induction Sealing Machines Market is primarily driven by the Asia Pacific region, accounting for 42% of the market's total share.

- Growth Opportunity: Advancements in automation technology and increasing demand for packaged food and beverages present substantial growth opportunities for induction sealing machines.

Driving factors

High Demand in Food and Beverage Industries

The homogenizers market is experiencing significant growth due to the high demand in the food and beverage industries. The increasing consumption of dairy products, beverages, and processed foods necessitates the use of homogenizers to ensure product consistency, stability, and quality. Homogenizers are essential in creating uniform mixtures and improving the texture and shelf life of products.

The food and beverage sector accounts for a substantial share of the homogenizers market, driven by the need for efficient processing technologies. As consumer preferences shift towards healthier and more convenient food options, manufacturers are increasingly adopting homogenization techniques to meet these demands, thereby boosting the market's growth.

Technological Advancements

Technological advancements play a crucial role in the expansion of the homogenizers market. Innovations such as high-pressure homogenizers and ultrasonic homogenizers have enhanced the efficiency and effectiveness of homogenization processes. These advancements allow for better control over particle size reduction, improved product quality, and energy efficiency. The integration of automation and digitalization in homogenizers has further optimized operations, reducing manual intervention and operational costs.

These technological improvements have made homogenizers more attractive to various industries, contributing to their widespread adoption and driving market growth. For instance, the introduction of nanotechnology in homogenization has opened new avenues for product development, particularly in pharmaceuticals and cosmetics, where precise particle size control is critical.

Growth in Pharmaceuticals and Cosmetics

The growth in the pharmaceuticals and cosmetics industries is a significant driver of the homogenizers market. In pharmaceuticals, homogenizers are essential for producing stable emulsions and suspensions, critical for drug formulation and delivery. The increasing demand for personalized medicine and advanced drug delivery systems has heightened the need for high-quality homogenization.

In the cosmetics industry, homogenizers are used to create fine, stable emulsions for cream, lotions, and other skincare products. The rising consumer awareness and demand for high-performance beauty and personal care products have led to increased investment in homogenization technologies. According to industry statistics, the pharmaceuticals and cosmetics sectors are among the fastest-growing end-users of homogenizers, significantly contributing to the market's overall expansion.

Restraining Factors

High Initial Costs

High initial costs present a significant barrier to the expansion of the homogenizers market. The advanced technology and specialized equipment required for homogenization processes involve substantial capital investment, which can be a deterrent for small and medium-sized enterprises (SMEs). These costs include not only the purchase of the homogenizers themselves but also the expenses related to installation, maintenance, and operator training.

High-pressure homogenizers, known for their efficiency and effectiveness, are particularly costly. This financial burden can limit the market penetration and adoption rate of homogenizers, especially in emerging markets where budget constraints are more pronounced. Consequently, despite the numerous benefits offered by homogenization, the high initial investment can slow down the overall market growth, particularly among smaller players in the industry.

Regulatory Requirements

Regulatory requirements significantly influence the homogenizers market by ensuring product safety, quality, and environmental compliance. Various industries, including food and beverage, pharmaceuticals, and cosmetics, are subject to stringent regulations that mandate the use of specific homogenization processes to meet health and safety standards. In the food and beverage industry, regulations enforced by authorities like the FDA and EFSA require homogenization to ensure the microbiological safety and stability of products.

These regulatory requirements, while ensuring high standards, also impose additional costs and operational challenges on manufacturers. Companies must invest in compliance processes, certification, and regular audits, which can be both time-consuming and costly.

By Type Analysis

Automatic type machines hold a 45% market share.

In 2023, Automatic Type held a dominant market position in the "By Type" segment of the Induction Sealing Machines Market, capturing more than a 45% share. The widespread adoption of automatic induction sealing machines is driven by their high efficiency, precision, and ability to handle large-scale production demands with minimal human intervention. These machines are particularly favored in industries such as food and beverage, pharmaceuticals, and chemicals, where high throughput and consistent seal integrity are paramount.

Manual Type machines, while capturing a smaller share, are essential in applications requiring flexibility and lower production volumes. These machines are typically used in small businesses, laboratories, and niche markets where the cost of fully automated systems cannot be justified. The manual type offers simplicity and cost-effectiveness, making them ideal for startups and small-scale operations.

Semi-automotive Type induction sealing machines strike a balance between manual and automatic systems, providing increased efficiency and reduced labor compared to manual systems, but at a lower cost than fully automatic machines. They are suitable for medium-sized operations where moderate automation is needed to improve productivity without significant capital investment. These machines are often utilized in mid-sized companies in the food, cosmetics, and pharmaceutical sectors.

Others category includes specialized and customized induction sealing machines designed for unique applications. This segment addresses specific needs in various industries, such as packaging foams unusual container shapes or incorporating advanced features like smart sensors for quality control.

By Application Analysis

The food and beverages industry accounts for 40% of the market.

In 2023, Food & Beverages held a dominant market position in the "By Application" segment of the Induction Sealing Machines Market, capturing more than a 40% share. The significant presence of induction sealing machines in this sector is driven by the critical need to ensure product freshness, prevent contamination, and extend shelf life. These machines are widely used in sealing bottles, jars, and containers of various food and beverage products, providing tamper-evident and airtight seals that preserve quality and safety.

Pharmaceuticals follow closely, leveraging induction sealing technology to secure the packaging of medicines, supplements, and other health-related products. The stringent regulatory requirements for product safety and integrity in the pharmaceutical industry underscore the adoption of reliable sealing solutions. Induction sealing ensures that products are tamper-proof and contamination-free, meeting both safety standards and consumer trust.

Consumer Goods sector also makes significant use of induction sealing machines, particularly for personal care items, household chemicals, and other packaged products. The demand for secure, leak-proof packaging in this sector drives the use of induction sealing to ensure product integrity during transportation and storage. The ability to provide a clean, professional seal enhances product presentation and consumer confidence.

Others category includes applications in diverse fields such as chemicals, automotive fluids, and specialty products that require secure and tamper-evident packaging. Induction sealing machines in these applications ensure that the contents are protected from leakage and external contamination, maintaining product quality and safety.

Key Market Segments

By Type

- Manual Type

- Semi-automotive Type

- Automatic Type

- Others

By Application

- Food & Beverages

- Pharmaceuticals

- Consumer Goods

- Others

Growth Opportunity

Expansion in Emerging Markets

Emerging markets present substantial growth opportunities for the global homogenizers market in 2024. Rapid industrialization, urbanization, and increasing disposable incomes in regions such as Asia-Pacific, Latin America, and Africa are driving the demand for processed foods, beverages, pharmaceuticals, and cosmetics.

These regions are witnessing significant investments in manufacturing infrastructure, creating a fertile ground for the adoption of advanced homogenization technologies. As local companies seek to enhance product quality and meet rising consumer expectations, the demand for efficient and effective homogenizers is expected to surge, providing a significant boost to market growth.

Innovation in Product Formulations

Innovation in product formulations offers another promising avenue for market expansion. The ongoing development of new and improved formulations in the food and beverage, pharmaceutical, and cosmetics industries necessitates advanced homogenization techniques. For instance, the rise in functional foods, plant-based beverages, and personalized medicine requires precise particle size reduction and stable emulsions, which homogenizers are well-equipped to deliver.

Companies are increasingly investing in R&D to develop innovative products that cater to evolving consumer preferences. This trend not only drives the demand for advanced homogenizers but also fosters continuous technological advancements within the market.

Latest Trends

Energy-Efficient Homogenizers

In 2024, the global homogenizers market is expected to see a significant trend towards energy-efficient solutions. With rising energy costs and increasing awareness of environmental sustainability, manufacturers are prioritizing the development and adoption of homogenizers that minimize energy consumption. These energy-efficient homogenizers not only reduce operational costs but also align with global efforts to reduce carbon footprints.

The push for greener technologies is prompting companies to innovate and improve the energy efficiency of their equipment, which is likely to enhance the market's appeal to environmentally conscious industries and consumers.

Automation and IoT Integration

The integration of automation and the Internet of Things (IoT) is revolutionizing the homogenizers market. Automated homogenizers equipped with IoT capabilities offer enhanced precision, control, and monitoring of the homogenization process. These advanced systems allow for real-time data collection and analysis, enabling manufacturers to optimize operations, improve product quality, and reduce downtime.

The trend towards smart manufacturing is driving the adoption of these cutting-edge technologies, which not only increase efficiency but also provide valuable insights into the production process. As industries increasingly embrace Industry 4.0, the demand for automated and IoT-integrated homogenizers is set to rise.

Regional Analysis

In 2023, the Asia Pacific region held a dominant market position in the Induction Sealing Machines Market, capturing more than 42% share. The region benefits from cost-effective labor, abundant raw materials, and robust industrial growth, particularly in the food and beverage, pharmaceutical, and chemical sectors. Rapid urbanization, increasing disposable incomes, and growing consumer awareness about product safety and shelf life further bolster the demand for induction sealing machines in this region.

North America follows, characterized by a high demand for advanced packaging solutions and stringent regulatory standards. The U.S. and Canada are major contributors, with well-established food and beverage, pharmaceutical, and consumer goods industries. The focus on product safety, tamper-evidence, and sustainability drives the adoption of induction sealing machines.

Europe is another significant market for induction sealing machines, driven by stringent regulations regarding product safety and packaging standards. The European market is characterized by high consumer awareness and demand for premium products, which necessitates advanced sealing technologies. Europe maintained a considerable market share in 2023, benefiting from high regulatory standards and a well-established industrial base.

Middle East & Africa is experiencing steady growth, driven by increasing investments in the food and beverage and pharmaceutical sectors. Efforts to diversify economies and reduce reliance on oil revenue are also contributing to industrial growth in the region. The market in the Middle East & Africa is supported by the development of new manufacturing facilities and the adoption of advanced packaging technologies.

Latin America is emerging as a promising market for induction sealing machines, with Brazil and Mexico leading the growth. The region's market is driven by an expanding food and beverage industry, increasing healthcare expenditure, and the rising demand for consumer goods.

Key Regions and Countries

North America

- US

- Canada

- Mexico

Western Europe

- Germany

- France

- The UK

- Spain

- Italy

- Portugal

- Ireland

- Austria

- Switzerland

- Benelux

- Nordic

- Rest of Western Europe

Eastern Europe

- Russia

- Poland

- The Czech Republic

- Greece

- Rest of Eastern Europe

APAC

- China

- Japan

- South Korea

- India

- Australia & New Zealand

- Indonesia

- Malaysia

- Philippines

- Singapore

- Thailand

- Vietnam

- Rest of APAC

Latin America

- Brazil

- Colombia

- Chile

- Argentina

- Costa Rica

- Rest of Latin America

Middle East & Africa

- Algeria

- Egypt

- Israel

- Kuwait

- Nigeria

- Saudi Arabia

- South Africa

- Turkey

- United Arab Emirates

- Rest of MEA

Key Players Analysis

In 2024, the global Induction Sealing Machines Market is expected to witness substantial growth, driven by increasing demand for secure, tamper-evident packaging across various industries such as food and beverage, pharmaceuticals, and cosmetics. Key players are leveraging technological advancements and expanding their product portfolios to capture larger market shares.

Enercon Industries Corporation and Pillar Technologies Inc. are anticipated to maintain their leading positions through continuous innovation and a strong focus on customer-centric solutions. Enercon’s robust R&D capabilities and Pillar’s expertise in advanced induction sealing technologies enable them to meet the stringent requirements of diverse industries, ensuring high seal integrity and efficiency.

Zhejiang Brother Packing Machinery Co. and Beijing Yute are poised to capitalize on their competitive pricing and extensive distribution networks, particularly in the Asia-Pacific region. Their ability to offer cost-effective and reliable solutions makes them preferred partners for small and medium enterprises looking to enhance their packaging capabilities.

Lepel Corporation and KWT Machine Systems Co. continue to be formidable players with their comprehensive product ranges and strong global presence. Lepel’s long-standing reputation for quality and KWT’s focus on innovative solutions and customer service strengthen their market positions.

Relco UK and Dongguan Sammi are expected to expand their market share by focusing on high-efficiency systems and custom solutions. Their commitment to addressing specific industry needs, particularly in the food and beverage sector, enhances their appeal.

Parle and Accutek are anticipated to grow through strategic partnerships and technological advancements. Parle’s focus on pharmaceutical applications and Accutek’s versatile machinery solutions position them well to meet the evolving demands of the packaging industry.

Proking and CSO Tech will continue to serve niche markets with specialized sealing machines, leveraging their expertise and strong customer relationships. Their robust product designs and customization capabilities are key strengths.

Y-Fang Sealing Machine Ltd. and Nantong Hengli Packing Technology are poised for growth through their focus on innovation and expansion into emerging markets. Their ability to offer advanced sealing technologies at competitive prices supports their market expansion.

Vanguard Pharmaceutical Machinery and Arshad Electronics are expected to enhance their positions through technological innovation and strong industry expertise, particularly in the pharmaceutical sector where precision and reliability are critical.

Suzhou Bangerxu is likely to leverage its strong manufacturing capabilities and focus on quality to capture market share, particularly in the fast-growing Asia-Pacific region.

Market Key Players

- Enercon Industries Corporation

- Pillar Technologies Inc.

- Zhejiang Brother Packing Machinery Co.

- Beijing Yute

- Lepel Corporation

- KWT Machine Systems Co.

- Relco UK

- Dongguan Sammi

- Parle

- Accutek

- Proking

- CSO Tech

- Y-Fang Sealing Machine Ltd.

- Nantong Hengli Packing Technology

- Vanguard Pharmaceutical Machinery

- Arshad Electronics

- Suzhou Bangerxu

Recent Development

- In May 2024, Enercon Industries launched a new line of induction sealers with enhanced energy efficiency and faster sealing speeds for the food and beverage sector.

- In April 2024, Pillar Technologies: Unveiled advanced induction sealing machines with integrated quality control features for the pharmaceutical industry, ensuring product integrity and safety.

Report Scope

Report Features Description Market Value (2023) USD 1.3 Bn Forecast Revenue (2033) USD 2.4 Bn CAGR (2024-2033) 6.6% Base Year for Estimation 2023 Historic Period 2018-2023 Forecast Period 2024-2033 Report Coverage Revenue Forecast, Market Dynamics, Competitive Landscape, Recent Developments Segments Covered By Type (Manual Type, Semi-automotive Type, Automatic Type, Others), By Application (Food & Beverages, Pharmaceuticals, Consumer Goods, Others) Regional Analysis North America - The US, Canada, & Mexico; Western Europe - Germany, France, The UK, Spain, Italy, Portugal, Ireland, Austria, Switzerland, Benelux, Nordic, & Rest of Western Europe; Eastern Europe - Russia, Poland, The Czech Republic, Greece, & Rest of Eastern Europe; APAC - China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Malaysia, Philippines, Singapore, Thailand, Vietnam, & Rest of APAC; Latin America - Brazil, Colombia, Chile, Argentina, Costa Rica, & Rest of Latin America; Middle East & Africa - Algeria, Egypt, Israel, Kuwait, Nigeria, Saudi Arabia, South Africa, Turkey, United Arab Emirates, & Rest of MEA Competitive Landscape Enercon Industries Corporation, Pillar Technologies Inc., Zhejiang Brother Packing Machinery Co., Beijing Yute, Lepel Corporation, KWT Machine Systems Co., Relco UK, Dongguan Sammi, Parle, Accutek, Proking, CSO Tech, Y-Fang Sealing Machine Ltd., Nantong Hengli Packing Technology, Vanguard Pharmaceutical Machinery, Arshad Electronics, Suzhou Bangerxu Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) -

-

- Enercon Industries Corporation

- Pillar Technologies Inc.

- Zhejiang Brother Packing Machinery Co.

- Beijing Yute

- Lepel Corporation

- KWT Machine Systems Co.

- Relco UK

- Dongguan Sammi

- Parle

- Accutek

- Proking

- CSO Tech

- Y-Fang Sealing Machine Ltd.

- Nantong Hengli Packing Technology

- Vanguard Pharmaceutical Machinery

- Arshad Electronics

- Suzhou Bangerxu