Heat Stabilizers Market Product Type:(Organotin, Calcium Carbonate, Zinc-Based Stabilizers, Lead-Based Stabilizers, Others), Application:(Coatings & Floorings, Pipes & Fittings, Wires & Cables, Profiles & Tubing) By Region And Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, And Forecast 2024-2033

-

43132

-

Jan 2024

-

165

-

-

This report was compiled by Correspondence Linkedin | Detailed Market research Methodology Our methodology involves a mix of primary research, including interviews with leading mental health experts, and secondary research from reputable medical journals and databases. View Detailed Methodology Page

-

Heat Stabilizers Market Size, Share, Trends Analysis

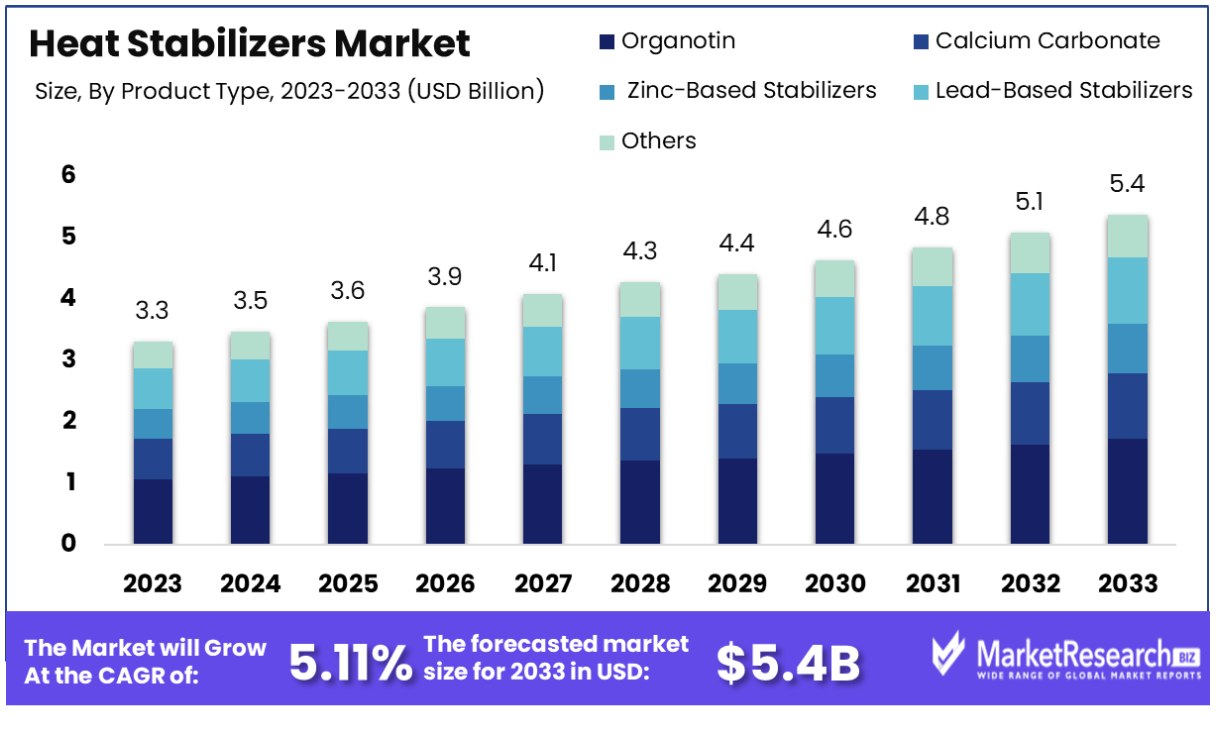

The heat stabilizers market was valued at USD 3.3 billion in 2023. It is expected to reach USD 5.4 billion by 2033, with a CAGR of 5.11% during the forecast period from 2024 to 2033.

The surge in demand for plastic products and the end-user industry are some of the main driving factors for the industrial stabilizers market. Heat stabilizers are commonly used to avoid the degradation of plastics by heat, especially at the time of the manufacturing process and also in applications.

For example, these are used in PVC elements. Heat stabilizers prevent thermal oxidation by attacking the disintegrated products of oxidation. Due to its structure, PVCs are particularly delicate to heat. Heat stabilizers are widely used in the PV industry and require the most heat stabilizers. Heat stabilizers also consist of recycled products, which play a significant role in stopping the degradation and destabilizing the after-use plastic waste. Heat stabilizers are organic and inorganic elements that comprise metal, and organic elements contain more active functions than metals.

The main function of the heat stabilizers in the PVC is to stop the PVC materials from degrading. When the PVC is exposed to sunlight it gets degraded thermally resulting in reduced performance, mechanical strength, and discoloration. Heat stabilizers neutralize free radicals at the time degradation process by stopping the further decline and consuming the polymer’s reliability. They also help in the consumption of PVS’s molecular structure by making sure of its chemical integrity and resistance to chemical reactions.

Heat stabilizers are important in the plastic industry as they have an important role in manufacturing plastics by withstanding various conditions. Plastics are solid forms of materials that have several abilities of their own but plastics are vulnerable to other chemical elements and UV radiations. Heat stabilizers are essential to avoiding discoloration of plastics and melting due to too much heat.

The heat or thermal stabilizers are quite similar to the UV stabilizers but heat stabilizers are used to manage any temperatures instead of sun exposure. The right choice of thermal stabilizers will make the plastics durable in cold temperatures or under heat, it all depends upon the combination of the additives. Heat stabilizers will continue to see high demand from plastic and PVC industries, helping market expansion.

Driving Factors

Diverse Applications Fuel Heat Stabilizers Market Growth

The growing demand for heat stabilizers in applications such as pipes & fittings, wires & cables, coatings & floorings, and profiles & tubing is significantly driving market growth. These materials are essential in providing products with maximum resilience to heat and environmental stresses. As industries continue to expand and demand more robust materials, the need for effective heat stabilizers is expected to rise, supporting a broad spectrum of applications and fueling market expansion.

Regulatory Environment Shapes Eco-friendly Innovations

The presence of stringent regulations regarding the use of toxic materials is profoundly influencing the heat stabilizers market. There's a concerted push towards developing and adopting more environmentally friendly heat stabilizers. Manufacturers are innovating to create products that comply with these regulations while maintaining or improving performance. This shift is not only a response to legal requirements but also aligns with the growing consumer and industrial demand for sustainable materials, contributing significantly to market growth.

Technological Advancements Drive Market Evolution

The market is benefiting considerably from technological advancements leading to the development of lightweight, renewable, and less toxic heat stabilizer products. The Asia-Pacific region, known for its rapid industrial growth and innovation, is particularly witnessing this trend. As industries seek materials that contribute to sustainability and efficiency, these advanced heat stabilizers are becoming increasingly popular. This push towards innovative, high-performance materials is likely to continue, driving the market forward and setting new standards in material science.

Restraining Factors

Stringent Regulations on Toxic Materials Restrain Heat Stabilizers Market Growth

Many heat stabilizers contain chemicals that can be harmful to the environment and human health. As a result, regulatory bodies across the globe have imposed strict guidelines on their use, limiting the types of materials that can be used in heat stabilizers.

These regulations force manufacturers to invest in research and development of safer, non-toxic alternatives, which can be costly and time-consuming. Compliance with these stringent standards can increase production costs and restrict market expansion as companies struggle to adapt.

Volatility in Raw Material Costs Impacts Heat Stabilizers Market Profitability

The heat stabilizers market is affected by potential large changes in the cost of raw materials required to produce heat stabilizers, which can significantly impact a company's profitability and pricing strategies. The prices of key raw materials, such as metals, chemicals, and plastic resins, can fluctuate due to various factors, including supply chain disruptions, geopolitical tensions, and changes in global demand.

These fluctuations make it challenging for manufacturers to maintain consistent pricing and profit margins. Companies may need to adjust their pricing frequently, which can lead to uncertainty in the market and potentially make customers hesitant to make long-term commitments.

Heat Stabilizers Market Segmentation Analysis

Product Type:

Organotin stabilizers have established themselves as the dominant segment within the heat stabilizers market. Their dominance can be attributed to their high efficiency and performance in stabilizing PVC and other chlorinated polymers against heat degradation. Organotin compounds are particularly valued in applications requiring clarity and transparency, making them the preferred choice for products like food packaging and medical devices.

While Organotin leads, other stabilizers like Calcium Carbonate, Zinc-Based, and Lead-Based stabilizers also hold substantial shares in the market. Calcium Carbonate is favored for its cost-effectiveness and non-toxic nature, Zinc-Based stabilizers are preferred for their balance of performance and safety, and Lead-Based stabilizers, though declining due to regulatory restrictions, have historically been used for their excellent heat-stabilizing properties. Each type of stabilizer caters to specific industry needs, influencing their application and market demand.

Application:

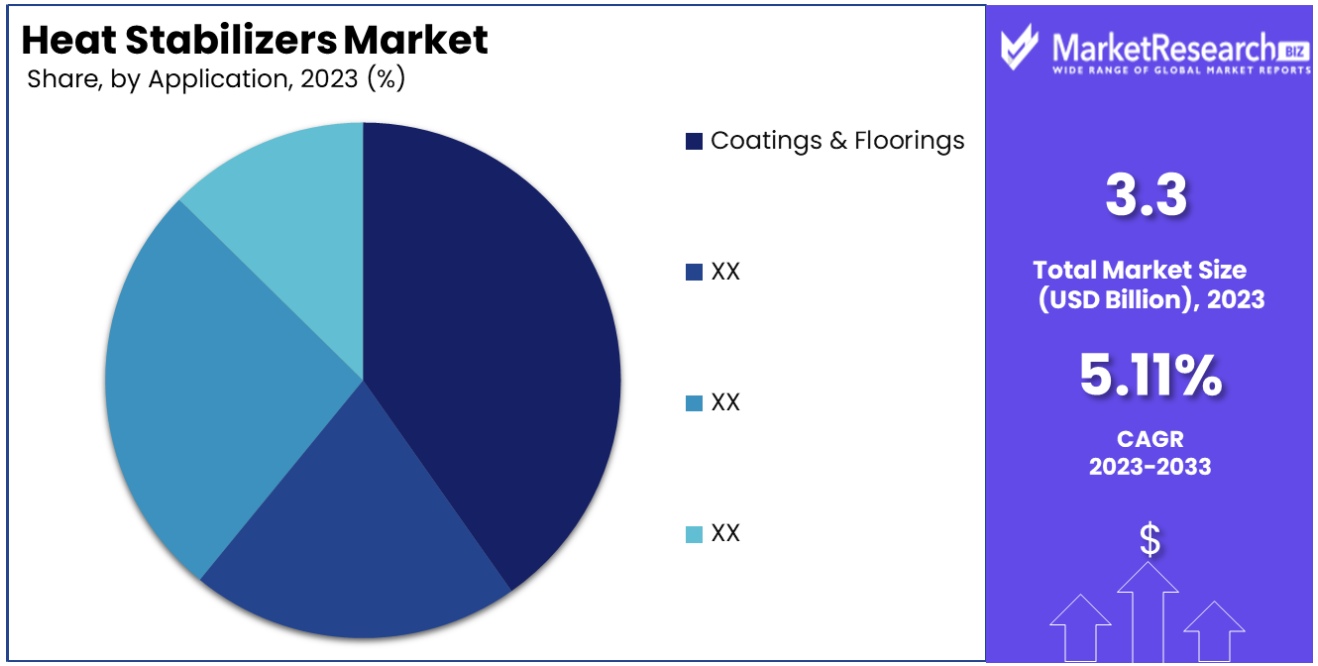

Coatings & Floorings have quickly become the dominant application in the heat stabilizers market. Due to the demand for long-lasting finishes in residential, commercial, and industrial settings, heat stabilizers play an essential role. Stabilizers used in coatings & floorings ensure materials retain their integrity, appearance, and performance over time when exposed to heat & light exposure.

While coatings and floorings lead, other applications like Pipes & Fittings, Wires & Cables, and Profiles & Tubing also significantly contribute to the market. Pipes & Fittings require stabilizers to maintain material strength and prevent premature failure, Wires & Cables need stabilizers to ensure insulation properties are retained over time, and Profiles & Tubing benefit from stabilizers to maintain structural integrity and aesthetic appeal.

Heat Stabilizers Industry Segments

Product Type:

- Organotin

- Calcium Carbonate

- Zinc-Based Stabilizers

- Lead-Based Stabilizers

- Others

Application:

- Coatings & Floorings

- Pipes & Fittings

- Wires & Cables

- Profiles & Tubing

Growth Opportunities

Growing Demand for Organic-Based Solutions Boosts Heat Stabilizers Market

As these sectors continue to expand and evolve, there's a rising preference for materials that are safer and more sustainable. Organic heat stabilizers, known for their lower toxicity and environmental impact, are becoming increasingly popular in response to consumer demand for greener products. This trend is creating substantial opportunities for companies producing organic heat stabilizers, as they strive to meet the market's growing need for eco-friendly and health-conscious materials.

Strict Regulations Spur Development of Low-VOC Organic Thermal Stabilizers

Strict regulations governing the consumption of toxic materials have led to the development and adoption of low-VOC (Volatile Organic Compounds) organic thermal stabilizers, contributing significantly to market growth. Regulatory bodies worldwide are imposing tighter controls on materials used in various industries to protect human health and the environment. This regulatory pressure is prompting manufacturers to innovate and develop heat stabilizers that meet these stringent standards while maintaining performance. The shift towards low-VOC, environmentally friendly stabilizers represents a growing market segment fueled by regulatory compliance and the broader move toward sustainability.

Heat Stabilizers Market Regional Analysis

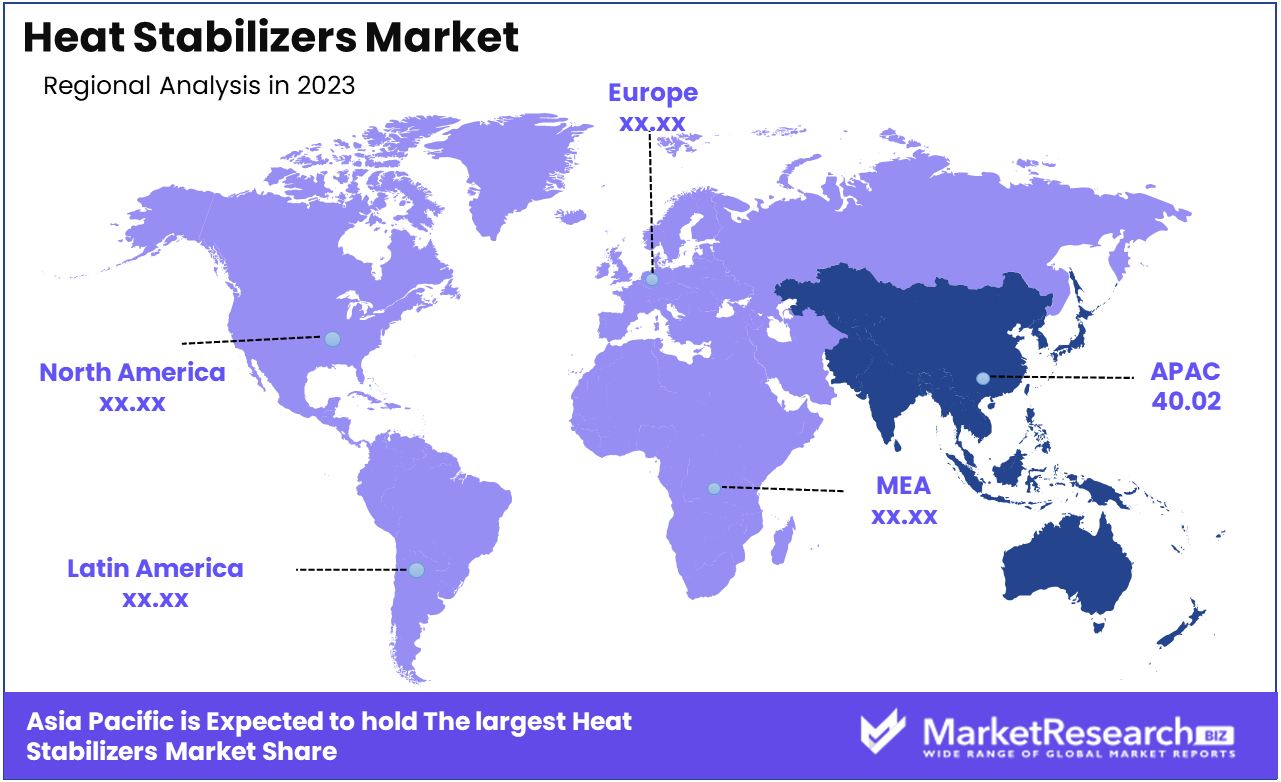

Asia-Pacific Dominates with 40.02% Market Share in Heat Stabilizers Market

Asia-Pacific's substantial 40.02% share in the heat stabilizers market is largely driven by the region's booming construction and automotive industries, particularly in countries like China, India, and Japan. The increasing demand for PVC and other polymers that require heat stabilization for manufacturing pipes, cables, and fittings is a significant contributor. Additionally, the region's rapid industrialization, coupled with the growing middle-class population and urbanization, amplifies the demand for consumer goods and electronics, further bolstering the market for heat stabilizers.

Asia-Pacific market dynamics are determined by its cost-competitive manufacturing environment and availability of raw materials, with infrastructure development projects necessitating heat-resistant materials and automotive sector expansion necessitating durable heat stabilizers for durability purposes. Furthermore, growing environmental awareness and sustainable practices have seen eco-friendly formulations emerging that reshape the market landscape.

North America: Advanced Material Usage and Stringent Regulations

North America's heat stabilizer market is driven by advanced material usage in various industries and strict environmental and safety regulations. Furthermore, high-quality materials in the construction and automotive sectors fuel an increase in heat stabilizer consumption in this region. The market benefits from the presence of key industry players and a strong emphasis on research and development.

Europe: Focus on Sustainability and High-Quality Standards

Europe's heat stabilizer market stands out for its strong commitment to sustainability and high-quality standards, driven by stringent environmental regulations and an increase in green building initiatives driving demand for advanced heat stabilizers. Europe’s well-established automotive and construction industries, along with the growing renewable energy sector, provide substantial opportunities for the heat stabilizers market. The commitment to maintaining high industrial standards and the emphasis on eco-friendly formulations are expected to continue driving the market in Europe.

Heat Stabilizers Industry By Region

North America

- The US

- Canada

- Rest of North America

Europe

- Germany

- France

- The UK

- Spain

- Italy

- Russia

- Netherlands

- Rest of Europe

Asia-Pacific

- China

- Japan

- South Korea

- India

- New Zealand

- Singapore

- Thailand

- Vietnam

- Rest of

Latin America

- Brazil

- Mexico

- Rest of Latin America

Middle East & Africa

- South Africa

- Saudi Arabia

- UAE

- Rest of Middle East & Africa

Heat Stabilizers Market Key Player Analysis

In the heat stabilizers market, companies such as Baerlocher GmbH, BASF SE hold significant positions, driving innovation and setting market standards. Baerlocher GmbH is recognized for its comprehensive range of stabilizers, catering to a variety of industrial needs, and its commitment to sustainability.

Adeka Corporation stands out with its technologically advanced solutions and strong research focus, while Clariant is known for its tailored solutions and global reach, providing stabilizers that enhance the durability and performance of plastics.

Companies like Kisuma Chemicals, GOLDSTAB ORGANICS PVT LTD, and Galata Chemicals also play significant roles in the market with their specialized products and strategic regional presence. Modern Chemicals and Plastics and Amfine Chemical Corporation contribute to market diversity with their unique formulations and customer-centric approaches.

Heat Stabilizers Industry Key Players

- Kisumu Chemicals (Netherlands)

- GOLDSTAR ORGANICS PVT LTD (India)

- Galata Chemicals (US)

- MODERN CHEMICALS AND PLASTICS (India)

- ADEKA CORPORATION (Japan)

- Baerlocher GmbH (Germany)

- Amfine Chemical Corporation (US)

- Chemson Polymer-Additive AG (Austria)

- Clariant (Switzerland)

- BASF SE (Germany)

- BRUNO BOCK (Germany)

- REAGENT SPA (Italy)

- PMC Organometallix Inc. (US)

- Adeka Corporation (Japan)

- Songwon Industrial Co. Ltd. (South Korea)

- Ika Innovative Kunststoffaufbereitung GmbH & Co. Kg (Germany)

- Valtris Specialty Chemicals (US)

- Am Stabilizers Corporation (US)

- Asúa Products, S.A. (Spain)

Heat Stabilizers Market Recent Development

- In January 2021, According to a BASF announcement, prices for plastic additives such as PVC heat stabilizers, pigments, processing aids, lubricants, UV stabilizers, and antioxidants would increase by up to 10% starting immediately.

Report Scope

Report Features Description Market Value (2023) USD 3.3 Billion Forecast Revenue (2033) USD 5.4 Billion CAGR (2024-2032) 5.11% Base Year for Estimation 2023 Historic Period 2016-2023 Forecast Period 2024-2033 Report Coverage Revenue Forecast, Market Dynamics, COVID-19 Impact, Competitive Landscape, Recent Developments Segments Covered Product Type:(Organotin, Calcium Carbonate, Zinc-Based Stabilizers, Lead-Based Stabilizers, Others), Application:(Coatings & Floorings, Pipes & Fittings, Wires & Cables, Profiles & Tubing) Regional Analysis North America - The US, Canada, Rest of North America, Europe - Germany, France, The UK, Spain, Italy, Russia, Netherlands, Rest of Europe, Asia-Pacific - China, Japan, South Korea, India, New Zealand, Singapore, Thailand, Vietnam, Rest of Asia Pacific, Latin America - Brazil, Mexico, Rest of Latin America, Middle East & Africa - South Africa, Saudi Arabia, UAE, Rest of Middle East & Africa Competitive Landscape Kisumu Chemicals (Netherlands), GOLDSTAR ORGANICS PVT LTD (India), Galata Chemicals (US), MODERN CHEMICALS AND PLASTICS (India), ADEKA CORPORATION (Japan), Baerlocher GmbH (Germany), Amfine Chemical Corporation (US), Chemson Polymer-Additive AG (Austria), Clariant (Switzerland), BASF SE (Germany), BRUNO BOCK (Germany), REAGENT SPA (Italy), PMC Organometallix Inc. (US), Adeka Corporation (Japan), Songwon Industrial Co. Ltd. (South Korea), Ika Innovative Kunststoffaufbereitung GmbH & Co. Kg (Germany), Valtris Specialty Chemicals (US), Am Stabilizers Corporation (US), Asúa Products, S.A. (Spain), Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) -

-

- Kisumu Chemicals (Netherlands)

- GOLDSTAR ORGANICS PVT LTD (India)

- Galata Chemicals (US)

- MODERN CHEMICALS AND PLASTICS (India)

- ADEKA CORPORATION (Japan)

- Baerlocher GmbH (Germany)

- Amfine Chemical Corporation (US)

- Chemson Polymer-Additive AG (Austria)

- Clariant (Switzerland)

- BASF SE (Germany)

- BRUNO BOCK (Germany)

- REAGENT SPA (Italy)

- PMC Organometallix Inc. (US)

- Adeka Corporation (Japan)

- Songwon Industrial Co. Ltd. (South Korea)

- Ika Innovative Kunststoffaufbereitung GmbH & Co. Kg (Germany)

- Valtris Specialty Chemicals (US)

- Am Stabilizers Corporation (US)

- Asúa Products, S.A. (Spain)