Grinding Machinery Market By Type (Cylindrical, Surface, Gear, Other), By End-User (Aerospace & Defense, Automotive, Other), By Region And Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, And Forecast 2023-2032

-

39527

-

July 2023

-

179

-

-

This report was compiled by Kalyani Khudsange Kalyani Khudsange is a Research Analyst at Prudour Pvt. Ltd. with 2.5 years of experience in market research and a strong technical background in Chemical Engineering and manufacturing. Correspondence Sr. Research Analyst Linkedin | Detailed Market research Methodology Our methodology involves a mix of primary research, including interviews with leading mental health experts, and secondary research from reputable medical journals and databases. View Detailed Methodology Page

-

Quick Navigation

Report Overview

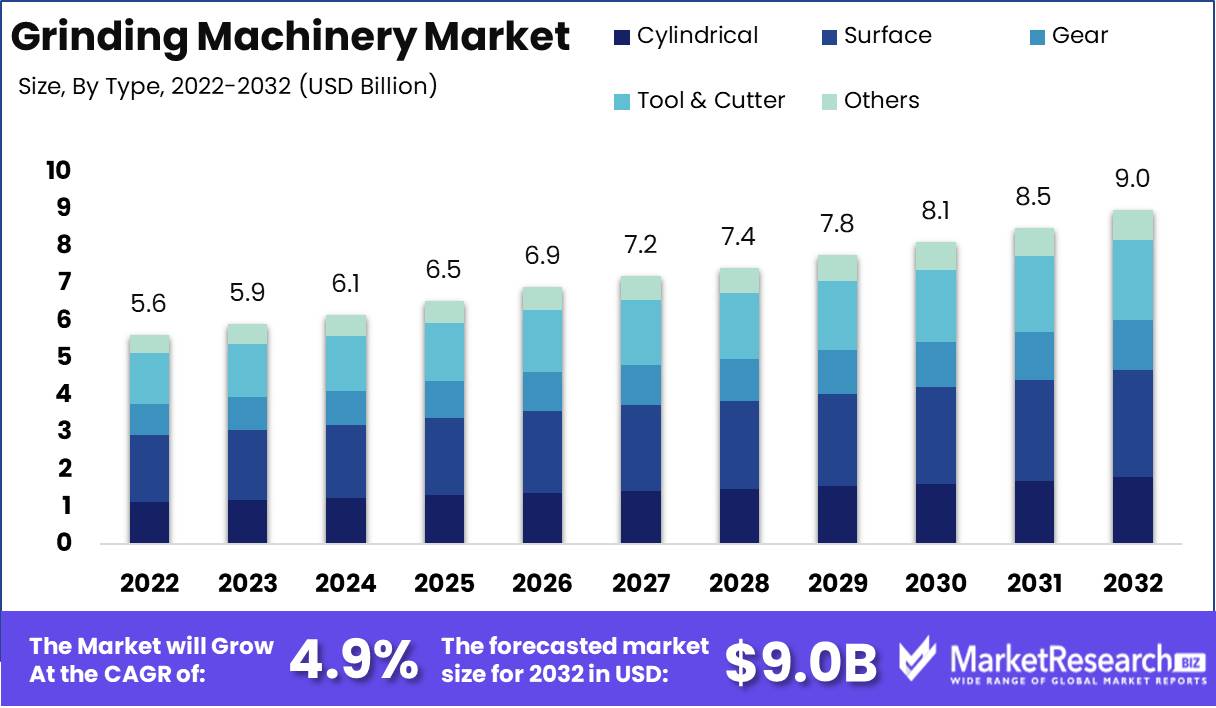

The Grinding Machinery Market size is expected to be worth around USD 9.0 Bn by 2032 from USD 5.6 Bn in 2022, growing at a CAGR of 4.9% during the forecast period from 2023 to 2032.

The grinding machinery market, an extensive realm that encompasses the design, production, and distribution of grinding machines, is a complex labyrinth. These ingenious contraptions remove material from a workpiece, paving the path to a brilliant surface finish. The burgeoning demand for grinding machinery, which spans diverse industries such as manufacturing, automotive, aerospace, and construction, is driven by the need for precise and efficient grinding solutions that produce flawless outputs.

At the core of the grinding machinery market is the overarching objective of providing industries with cutting-edge equipment able to deftly annual material and weave the tapestry of the desired surface finish. These engineering marvels, equipped with abrasive wheels or belts, set out on an arduous odyssey of grinding the workpiece to satiate the need for precise specifications. Unyielding in its pursuit of evolution, the market strives to provide an ever-expanding selection of innovative grinding machinery, meticulously designed to meet the diverse needs of numerous industries.

The grinding machinery market is a hub of paramount importance in industries where precision and surface finish govern supreme. Manufacturers leave their impression on the realm of high-quality goods by leveraging the ability to grind materials with surgical precision and unwavering efficiency. Whether producing the ideal surface finish for a component or orchestrating the intricate dance of material grinding to satisfy minute tolerances, grinding machinery confers a variety of benefits to its users.

The grinding machinery market has emerged from the ashes of obscurity like a phoenix, fueled by technological innovation, rising demand for superior products, and the grandeur of industrialization. In order to satisfy the demands of a variety of industries, a company must have a strong presence in the market. Grinding machinery, as a beneficent deity, bestows its divine presence upon a vast pantheon of industries, spanning the domains of manufacturing, automotive, aerospace, medical, oil and gas, and construction.

The grinding machinery market weaves its tapestry of destiny, and ethical dilemmas emerge, casting a disquieting shadow over its dominance. Environmental impact, worker safety, and the adoption of sustainable practices are entangled within the discourse's delicate fabric. As virtuous sentinels, industry titans now fix their unwavering attention on the altar of responsible manufacturing and sustainable operations. A pantheon of endeavors is forming, enshrined in the sanctum of energy consumption reduction, waste generation minimization, and the harmonious union of grinding techniques and environmental consciousness.

Driving factors

Demand for Accurate and Superior Finishes in the Grinding Machinery Market

The demand for precision and high-quality finishes has risen to the top of the manufacturing industry's priority list as it continues to evolve. Automotive, aerospace, construction, and even automation have witnessed an increase in the demand for grinding machinery that can produce exceptional results. With the advancement of technology and the advent of Industry 4.0, the market for grinding machinery has evolved to meet these rising demands.

Growth in the Automotive and Aerospace Industries Drives the Grinding Machinery Market

In terms of both production and technological development, the automotive and aerospace industries have experienced substantial expansion. This expansion has resulted in a surge in the demand for precision components, for which grinding machinery is indispensable. To ensure the optimal performance and safety of automotive and aerospace applications, grinding machines are utilized to achieve precise tolerances and high-quality surface finishes.

Automation and Industry 4.0 Transform the Grinding Machinery Market

Automation has revolutionized a variety of industries, including the grinding machinery market. The incorporation of automated systems into grinding machines has increased efficiency, improved precision, and decreased labor costs. Industry 4.0, also referred to as the fourth industrial revolution, propels this transformation further. With the implementation of intelligent technologies, grinding machines can now communicate, analyze data, and optimize themselves, ensuring efficient operations and meeting the demand for precision and high-quality finishes.

Construction Industry Expansion Drives Grinding Machinery Market

Due to population growth and urbanization, the construction industry is experiencing accelerated growth. This expansion necessitates the production of precise and high-quality construction components, which can be accomplished with grinding machinery. To fabricate materials with precise dimensions and surface finishes, thereby ensuring structural integrity and aesthetic appeal, builders and contractors require dependable grinding machines.

The Prevalence of CNC Machines in the Grinding Machinery Market

On the market for grinding machinery, CNC (Computer Numerical Control) machines have acquired tremendous traction. These machines use computer-aided design (CAD) and computer-aided manufacturing (CAM) software to automate and control different aspects of the grinding process. CNC machines offer improved precision, adaptability, and productivity, making them indispensable for attaining the quality and finishes desired in a variety of industries.

Prospects for the Grinding Machinery Market

As the demand for precision and high-quality finishes continues to increase, the grinding machinery market has a bright outlook. The automotive, aerospace, construction, and automation industries will continue to drive the market to greater heights. The advancement of technology, such as artificial intelligence, machine learning, and robotics, has led to the development of a number of new technologies.

Restraining Factors

The Cost of a Grinding Machine is a Major Factor in the Growth of the Industry

The high price of these machines is one of the primary factors restraining market expansion in the grinding machinery industry. The cost of a new car is a major factor in the cost of a new car. In addition, the cost of maintenance, tools, and consumables contributes to the total expenditures. These financial obstacles present a challenge for industry participants, resulting in a slower adoption rate for new grinding machinery.

Emerging Technologies Challenge Grinding Machinery

The availability of substitute technologies represents a further significant market constraint for grinding machinery. While manufacturers have long relied on conventional grinding machinery, new technologies such as additive manufacturing and laser cutting are gaining ground. These alternatives provide quicker processing times, higher precision, and greater adaptability, thereby challenging the dominance of conventional grinding machinery.

Technological Ambiguity Limit Grinding Machinery Market

The technological complexities of the grinding machinery market are also a significant factor in restraining its growth. As the evolution of advanced manufacturing processes continues, grinding machines must adapt to the most recent industry trends. It is now essential to integrate robotics, automation, and computer numerical control (CNC) systems. This presents manufacturers with a challenge in terms of technology adoption, machine programming, and operator training.

Sustainability Tensions on the Grinding Machinery Market

In today's environmentally conscious world, there is pressure on the grinding machinery market to reduce its carbon footprint and enhance its sustainability. Significant quantities of noise, vibrations, and emissions are produced by grinding processes, which contribute to environmental pollution. The challenges encountered by the industry are exacerbated by the fact that the government has a history of enforcing strict regulations on its own citizens.

Labor Shortage in the Grinding Machinery Industry

The grinding machinery market is highly dependent on skilled operators who have a comprehensive understanding of grinding processes and machine operation. However, a significant limitation remains the availability of a skilled workforce. Due to a dwindling workforce, there is a dearth of qualified technicians and operators in the industry. To bridge this skill disparity and ensure a competent workforce, businesses must invest in training programs.

Proactive Steps to Promote the Grinding Machinery Market

To overcome these restraining factors and promote growth in the grinding machinery market, industry participants must take proactive measures. Collaboration between machine manufacturers, research institutions, and consumers can foster innovation and alleviate cost-related challenges. By employing flexible pricing models or leasing options, manufacturers can alleviate the financial burden on small and medium-sized enterprises (SMEs) and encourage the widespread adoption of advanced grinding machinery.

Type Analysis

With the surface segment dominating the industry, the grinding machinery market has seen tremendous growth in recent years. The term "sea" refers to the process of obtaining a license to drive a vehicle. Due to its excellent surface finishes and precise dimensional precision, surface grinding machinery has been in high demand.

Economic growth in emerging markets is one of the main factors driving surface segment grinding machinery adoption. The United States of America's largest city, Chicago, has a long history of being a center of manufacturing. Emerging economies are driving surface segment growth in the grinding machinery market.

The following is a list of the most important factors to consider when deciding whether to purchase a product. The following is a list of the most important things to consider when purchasing a home. These industries choose surface grinders for their precision. The demand for surface grinding machinery has also increased due to the growing trend of automation in manufacturing processes.

The fastest-growing segment of the economy is the grinding machinery market, where the fastest-growing segment is the surface. Several factors cause this. First, precision component demand in the automotive, aerospace, and electronics industries is driving the need for sophisticated grinding machinery. These industries are expected to demand surface grinders due to their accuracy.

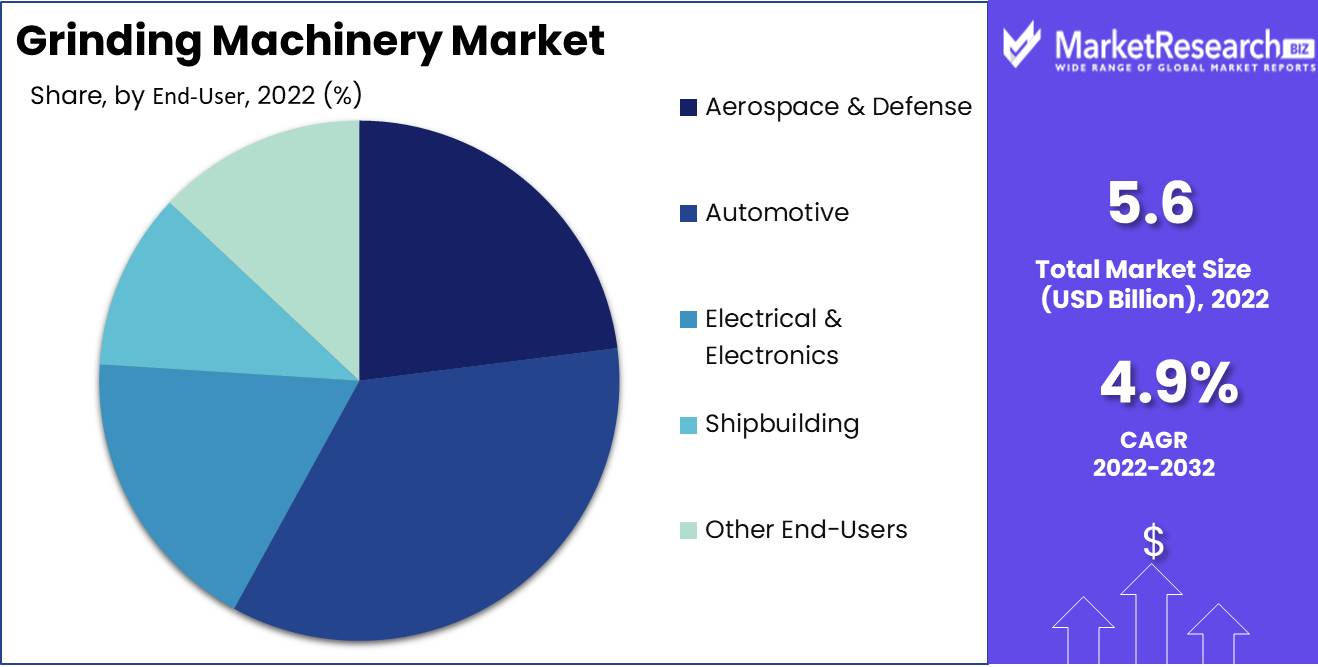

End-User Analysis

The automotive segment dominates the grinding machinery market. For engine, transmission, and brake parts, the automotive industry uses grinding machinery. Precision and quality drive automotive grinding machinery demand.

Like the surface segment, growing economies are driving the adoption of grinding machinery in the automotive industry. The growth of the economy in the United States is a direct result of the tremendous growth of the automotive industry. The increase in production has led to an increase in the number of people who are using the service.

Consumer trends and behaviors affect grinding machinery market growth in the automotive segment. The automotive industry is focusing on fuel efficiency and environmental sustainability. Precision finishes and dimensional control from grinding machinery help achieve these goals.

The fastest-growing industry in the world is the automotive industry, and the automotive industry is no exception. Several factors cause this. First, the increased demand for electric and hybrid vehicles is driving the need for specialist grinding machinery. Precision grinding is needed for these vehicles' electric motors and battery systems.

Key Market Segments

By Type

- Cylindrical

- Surface

- Gear

- Tool & Cutter

- Other Grinding Machinery

By End-User

- Aerospace & Defense

- Automotive

- Electrical & Electronics

- Shipbuilding

- Other End-Users

Growth Opportunity

Grinding Machines' Evolution

Advanced technology, growing markets, AI and machine learning integration, customization services, and sustainability have driven grinding machinery market growth. These dynamic elements have transformed the sector, creating huge growth potential and intriguing chances that can reshape grinding machinery in the next years.

AI Transforms Grinding Machinery

AI and machine learning have expanded the grinding machinery market. Manufacturers can improve productivity and accuracy by adopting advanced automation. AI-powered algorithms can evaluate massive data sets and optimize grinding processes in real-time, decreasing errors and downtime. This technology allows companies to keep ahead of the competition and meet customers' expanding wants, driving market growth.

Customization Boosts Grinding Machinery

The grinding machinery market must emphasize AI and machine learning integration. This disruptive strategy boosts productivity, lowers costs, improves product quality, and streamlines operations. Cutting-edge automation technologies help manufacturers build a sustainable future and uncover huge growth potential in the grinding machinery market environment.

Sustainable Grinding Machinery Market

Today's customers want customized solutions that meet their needs. Customization services offer a huge growth opportunity in the grinding machinery market. The company's website is a great place to start. Customization boosts consumer loyalty and repeats business.

Customized Grinding Machines

The term "soap" refers to the process of obtaining a license to drive. This urgent necessity has prompted the grinding machinery market to adopt sustainable practices and technology. Eco-friendly manufacturing, renewable energy, and resource optimization reduce carbon footprint and meet strict regulatory standards.

Green Methods Garner Market Advantage

The following is a list of all the companies that offer this service. In the grinding machinery market, sustainability appeals to environmentally conscious customers. With the help of a few simple tricks, you can increase your chances of success.

Latest Trends

Revolutionizing Precision Robotic Grinding Systems

Robotic systems have changed the grinding machinery market. These modern machines use robotics, automation, and artificial intelligence to improve operating efficiency and precision. Robotic grinding systems remove manual work, lowering downtime, mistakes, and productivity. Robotic systems revolutionized grinding with their precision and repeatability.

Versatility redefined Hybrid Grinding Machines

The grinding machinery market is trending toward hybrid machines as technology advances. These machines integrate numerous grinding operations into one platform, bridging technologies. Hybrid machines combine surface grinding, cylindrical grinding, and centerless grinding for adaptability. With the help of a few simple tricks, you can make your way to the top of the food chain.

IoT-Enabled Efficiency Smart Grinding Machinery

With the Internet of Things (IoT), grinding machinery market manufacturers are using connectivity and data analytics to innovate and improve efficiency. IoT-enabled grinding machines monitor temperature, vibration, and tool wear. Advanced analytics detect machine problems, schedule maintenance, and optimize performance. IoT and predictive maintenance help manufacturers reduce downtime, maintenance costs, and equipment performance.

Precision 5-Axis Grinding Machines

5-axis and multi-axis grinding machines are used for difficult parts due to demand. These machines let manufacturers do high-precision grinding on many axes simultaneously, enabling elaborate geometries and sophisticated surface finishing. These machines improve precision, cycle time, and surface quality by allowing simultaneous rotation and translation. To address precision component demand, aerospace, automotive, and medical industries are using 5-axis and multi-axis machines.

Superior Grinding Wheels

The only way to know if a product is good is to try it out. Modern grinding wheels have better cutting, longer life, and less dressing. These upgraded grinding wheels ensure consistent results, less downtime, and increased production. They are made with precision and ingenuity. By utilizing cutting-edge grinding wheel technology, manufacturers may achieve flawless precision and surface integrity.

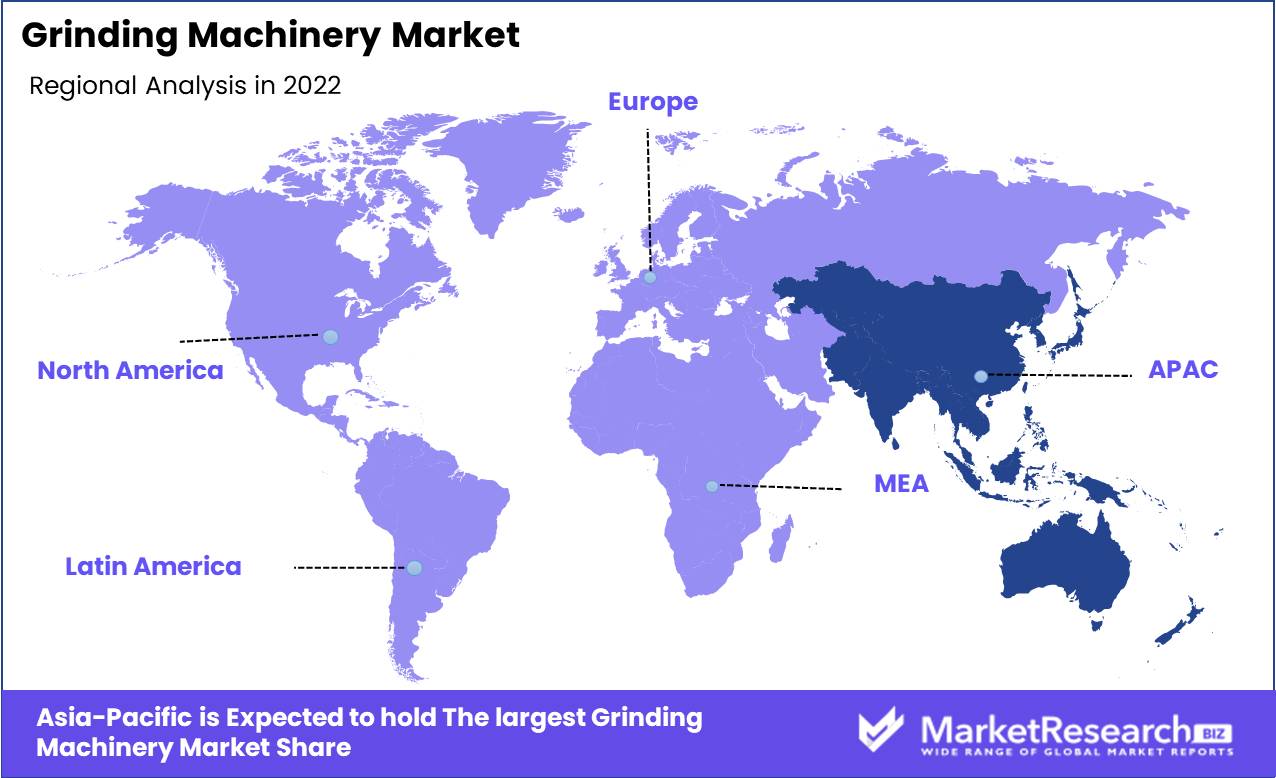

Regional Analysis

Asia-Pacific Leads Grinding Machinery Market The Asia-Pacific grinding machinery market dominates industrial manufacturing. This region has overtaken others due to economic expansion, technological advancements, and infrastructure development.

Asia-Pacific's extensive industrial environment helps it dominate the grinding machinery market. This region has a strong manufacturing base due to countries like China, Japan, South Korea, and India. These countries' automotive, aerospace, electronics, and construction industries have grown rapidly, driving grinding machinery demand.

Recent technological advancements in the Asia-Pacific region are also noteworthy. Research and development in this sector create cutting-edge grinding machinery. Advanced grinding machinery is in demand in the region due to manufacturing process efficiency, precision, and automation activities.

The Asia-Pacific region also attracts large infrastructure investments. Governments in countries like China and India have ambitious intentions to overhaul their infrastructure, generating a grinding machinery market. These projects include bridge, road, railway, airport, and industrial park construction. To support these infrastructure projects, high-quality grinding machinery is in high demand.

Key Regions and Countries

North America

- US

- Canada

- Mexico

Western Europe

- Germany

- France

- The UK

- Spain

- Italy

- Portugal

- Ireland

- Austria

- Switzerland

- Benelux

- Nordic

- Rest of Western Europe

Eastern Europe

- Russia

- Poland

- The Czech Republic

- Greece

- Rest of Eastern Europe

APAC

- China

- Japan

- South Korea

- India

- Australia & New Zealand

- Indonesia

- Malaysia

- Philippines

- Singapore

- Thailand

- Vietnam

- Rest of APAC

Latin America

- Brazil

- Colombia

- Chile

- Argentina

- Costa Rica

- Rest of Latin America

Middle East & Africa

- Algeria

- Egypt

- Israel

- Kuwait

- Nigeria

- Saudi Arabia

- South Africa

- Turkey

- United Arab Emirates

- Rest of MEA

Key Players Analysis

The majority of the time, the market for grinding machinery is dominated by companies that specialize in the process. Having said that, it's important to note that the majority of the time, the majority of the time, the majority of the time, the majority of the time, the majority of the time, the majority of the time.

Swiss multinational Rieter dominates the grinding machinery market. Rieter leads industry standards with its persistent commitment to innovation. The company's website is a great place to start. Sustainable techniques and energy efficiency have solidified Rieter's industry leadership.

Saurer Intelligent Technology AG, another Swiss company, has shaped the grinding machinery market. Saurer has helped improve technology with his precision and excellence. Their intuitive interfaces and advanced automation solutions have transformed grinding machinery. Saurer has earned global clients' trust and affection by being ahead of the curve.

American giant Murata Machinery USA, Inc. dominates the grinding machinery market. Murata Machinery has developed innovative solutions using cutting-edge technology by focusing on innovation and research. Their high-speed precision machinery and superior control systems demonstrate their commitment to customer satisfaction. Murata Machinery's dedication to excellence has made them an industry leader.

Indian business LAKSHMI MACHINE WORKS LIMITED has made major grinding machinery market advances. They were famous for their pioneering growth and development. LAKSHMI MACHINE WORKS LIMITED.'s commitment to customization and customized solutions has resonated with many sectors. They dominate the market by meeting client needs.

As a result of the company's commitment to its customers, the company has a reputation for providing high-quality products. Trützschler's knowledge and history since 1888 make them a trustworthy provider. Trützschler's winning recipe combines cutting-edge technology with handcraft. They've won industry praise for their eco-friendly operations.

Top Key Players in Grinding Machinery Market

- Rieter (Switzerland)

- Saurer Intelligent Technology AG (Switzerland)

- Murata Machinery USA, Inc. (U.S.)

- LAKSHMI MACHINE WORKS LIMITED (India)

- Trützschler (Switzerland)

- KIRLOSKAR TOYOTA TEXTILE MACHINERY PVT LTD. (India)

- A.T.E. Private Limited (India)

- Itema S.p.A. (Italy)

- Marzoli Grinding Solutions (Italy)

- Savio Macchine Tessili S.p.A. (Italy)

Recent Development

- In 2023, The introduction of this new technology in the automotive industry is anticipated to occur.

- In 2022, In order to make the most of your time and money, you need to be able to use the best tools available.

- In 2021, DMG MORI introduced the versatile DMU 85 monoBLOCK five-axis horizontal machining center, continuing a trend of revolutionary innovations.

- In 2020, Gear Manufacturing took a giant stride forward with the introduction of the Cyclo Grind 5000 grinding machine from Gleason Corporation.

- In 2019, Hardinge Inc. unveiled its revolutionary VG350 vertical grinding machine to keep up with the times.

Report Scope:

Report Features Description Market Value (2022) USD 5.6 Bn Forecast Revenue (2032) USD 9.0 Bn CAGR (2023-2032) 4.9% Base Year for Estimation 2022 Historic Period 2016-2022 Forecast Period 2023-2032 Report Coverage Revenue Forecast, Market Dynamics, COVID-19 Impact, Competitive Landscape, Recent Developments Segments Covered By Type (Cylindrical, Surface, Gear, Tool & Cutter, Other Grinding Machinery), By End-User (Aerospace & Defense, Automotive, Electrical & Electronics, Shipbuilding, Other End-Users) Regional Analysis North America – The US, Canada, & Mexico; Western Europe – Germany, France, The UK, Spain, Italy, Portugal, Ireland, Austria, Switzerland, Benelux, Nordic, & Rest of Western Europe; Eastern Europe – Russia, Poland, The Czech Republic, Greece, & Rest of Eastern Europe; APAC – China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Malaysia, Philippines, Singapore, Thailand, Vietnam, & Rest of APAC; Latin America – Brazil, Colombia, Chile, Argentina, Costa Rica, & Rest of Latin America; Middle East & Africa – Algeria, Egypt, Israel, Kuwait, Nigeria, Saudi Arabia, South Africa, Turkey, United Arab Emirates, & Rest of MEA Competitive Landscape Rieter (Switzerland), Saurer Intelligent Technology AG (Switzerland), Murata Machinery USA, Inc. (U.S.), LAKSHMI MACHINE WORKS LIMITED (India), Trützschler (Switzerland), KIRLOSKAR TOYOTA TEXTILE MACHINERY PVT LTD. (India), A.T.E. Private Limited (India), Itema S.p.A. (Italy), Marzoli Grinding Solutions (Italy), Savio Macchine Tessili S.p.A. (Italy) Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) -

-

- Rieter (Switzerland)

- Saurer Intelligent Technology AG (Switzerland)

- Murata Machinery USA, Inc. (U.S.)

- LAKSHMI MACHINE WORKS LIMITED (India)

- Trützschler (Switzerland)

- KIRLOSKAR TOYOTA TEXTILE MACHINERY PVT LTD. (India)

- A.T.E. Private Limited (India)

- Itema S.p.A. (Italy)

- Marzoli Grinding Solutions (Italy)

- Savio Macchine Tessili S.p.A. (Italy)