Geomembranes Market By raw material (High-density polyethylene (HDPE), Low-density polyethylene (LDPE), Ethylene propylene diene monomer (EPDM), and Others), By technology (Extrusion, Calendaring, Others), By application (Water Management, Waste Management, Mining, Tunnel Liners, Civil Engineering, Others), By Region And Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, And Forecast 2024-2033

-

2505

-

May 2023

-

171

-

-

This report was compiled by Research Team Research team of over 50 passionate professionals leverages advanced research methodologies and analytical expertise to deliver insightful, data-driven market intelligence that empowers businesses across diverse industries to make strategic, well-informed Correspondence Research Team Linkedin | Detailed Market research Methodology Our methodology involves a mix of primary research, including interviews with leading mental health experts, and secondary research from reputable medical journals and databases. View Detailed Methodology Page

-

Quick Navigation

Report Overview

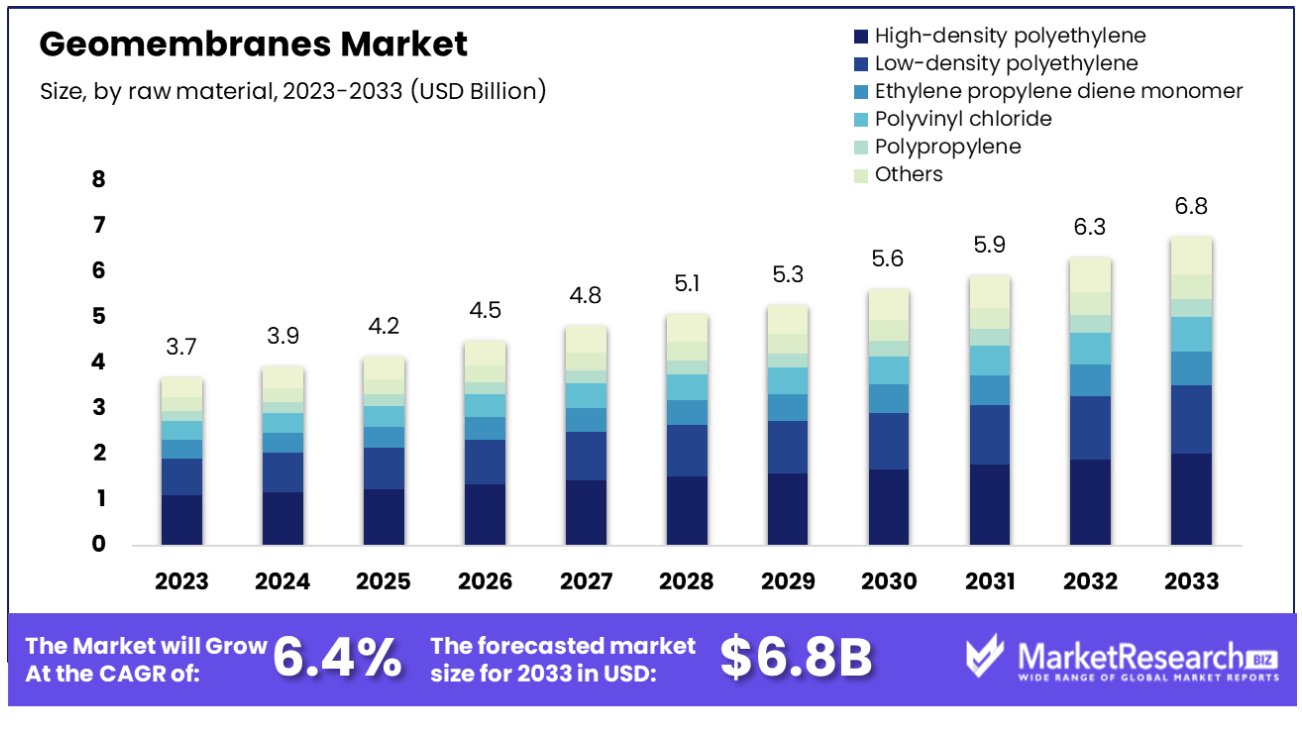

The Geomembranes Market size is expected to be worth around USD 6.8 Bn by 2033 from USD 3.7 Bn in 2023, growing at a CAGR of 6.4% during the forecast period from 2023 to 2033.

Within the field of geosynthetics, the swiftly expanding Geomembranes Market is a hotbed of innovation and progress. At the heart of this cutting-edge industry are flexible polymeric materials that serve as an impermeable barrier to prevent the infiltration and exfiltration of liquids and gases. These materials, which have extensive applications in the disciplines of construction and civil engineering, are an efficient method for managing, containing, and protecting the environment from hazardous and noxious contaminants.

A plethora of materials, including high-density polyethylene (HDPE), low-density polyethylene (LDPE), polyvinyl chloride (PVC), chlorosulfonated polyethylene (CSPE), and ethylene propylene diene monomer (EPDM), can be used to manufacture geomembranes. These synthetic sheets or films find widespread application in a variety of environmental containment applications, including but not limited to landfills, oil and gas lines, and mining sites.

There are numerous benefits to employing geomembranes in such situations, spanning from exceptional durability and strength to superior weather resistance, which increases the longevity of ponds and landfill liners. In addition, these materials exhibit resistance to a variety of compounds, ultraviolet light, and microbial decomposition. In addition, they facilitate the control and management of groundwater and surface water quality, which is of utmost importance to a wide range of industries, including agriculture, construction, mining, and petrochemicals.

The market for geomembranes has grown exponentially as a result of the allocation of substantial resources to research and development, manufacturing, and distribution. Increasingly, these versatile materials are incorporated into additional products, services, and applications to improve their efficacy and sustainability. For instance, they are used as a moisture barrier in the construction of green roofs and to increase the tensile strength and stability of geotextiles.

In the geomembranes market, the significance of sustaining ethical business practices cannot be overstated. As a key participant in environmental protection and management, geomembrane solutions must adhere to responsible and transparent business practices to be effective and sustainable. This requires the efficient management of waste disposal, the judicious procurement of basic materials, and an unwavering commitment to environmental standards. Such practices ultimately support the sustainable growth of the geomembranes market.

Key Takeaways

- Market Growth Projection: The Geomembranes Market size is expected to be worth around USD 6.42 Bn by 2032 from USD 3.45 Bn in 2022, growing at a CAGR of 6.4% during the forecast period from 2023 to 2032.

- By Raw Material Analysis: Driven by HDPE's exceptional properties and increased demand for environmental protection, is poised for significant expansion, particularly in emerging economies.

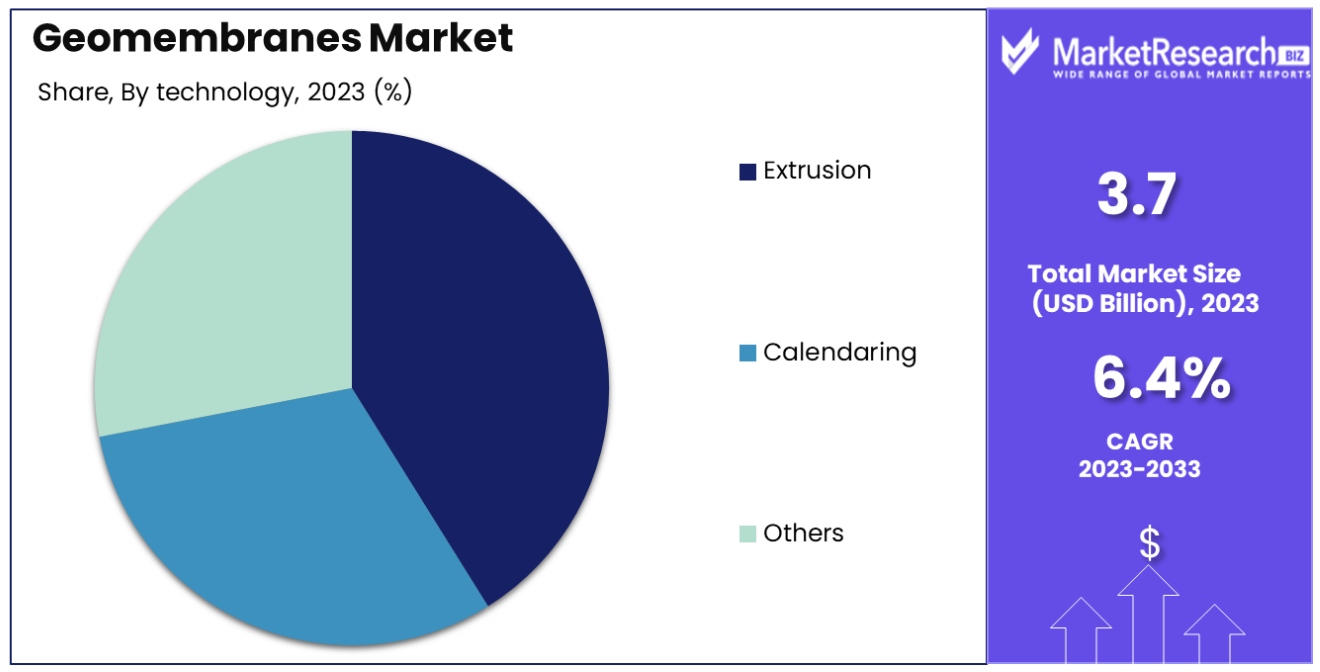

- By Technology Analysis: Extrusion technology dominates the geomembranes market due to its efficiency in producing liners of varying thicknesses with superior mechanical properties, meeting the rising demand driven by infrastructure development and environmental protection projects globally.

- By Application Analysis: Increasing demand in waste management, water management, and infrastructure development sectors, owing to their crucial role in environmental protection and sustainability initiatives globally.

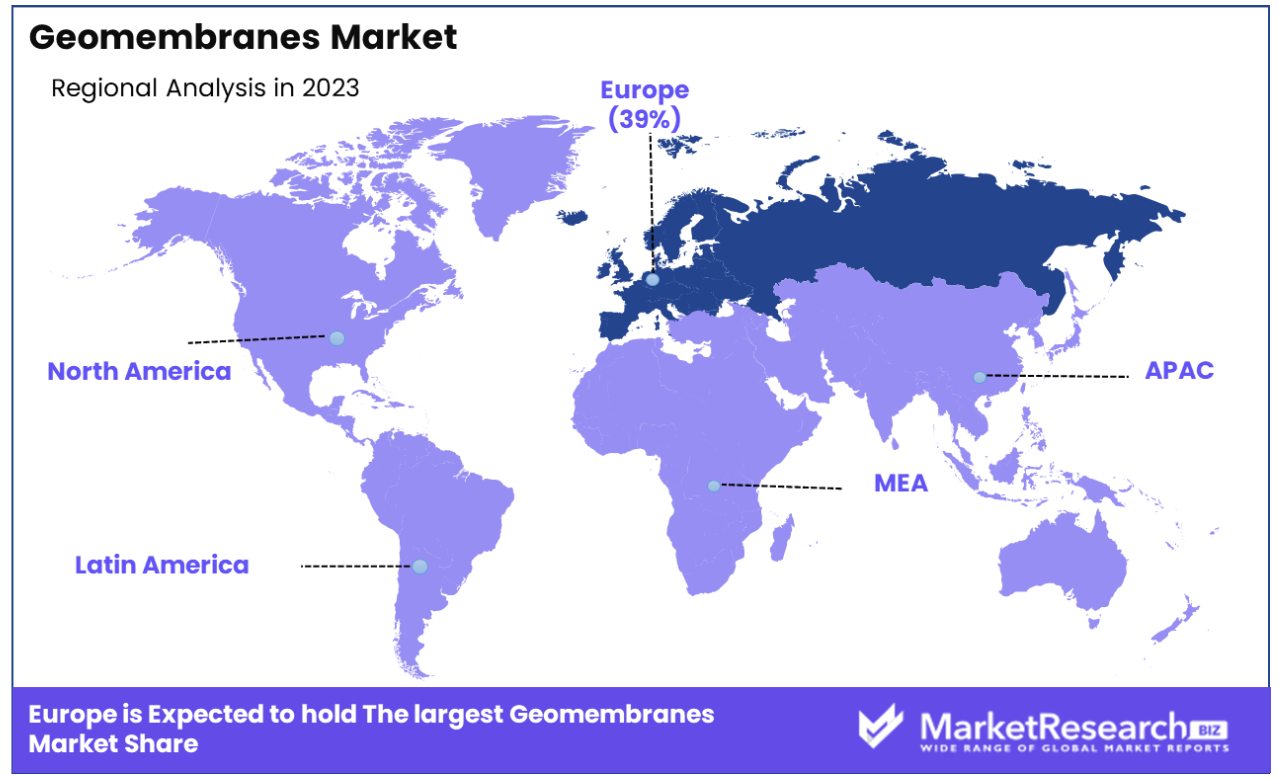

- Regional Analysis: Europe Dominates with a 39% Market Share

Driving factors

Water Conservation and Waste Management System Demand

In recent years, the demand for geomembranes has increased, and this trend is anticipated to continue due to several factors. Increasing demand for water conservation and waste management systems is one of the primary factors. Lining landfills, ponds, and other waste containment systems with synthetic geomembranes prevents seepage and protects groundwater from contamination. As global awareness of environmental issues grows, the demand for these systems will only increase.

Environmental Protection Regulations

The market is also being driven by rising environmental protection concerns and regulations regarding waste disposal. Governments around the globe are implementing more stringent regulations to prevent pollution and ensure safe waste disposal. This is anticipated to increase demand for geomembranes as industries seek sustainable and compliant waste management solutions.

Rapid Urbanisation and Industrialization

Increasing construction activities and infrastructure development in emerging economies are additional market drivers for geomembranes. Rapid urbanization and industrialization in developing nations have increased the demand for geomembranes in various construction and infrastructure projects. From the lining of canals and reservoirs to the construction of tunnels and storage facilities, geomembranes have a wide spectrum of industrial applications.

Expanding Applications in the Mining and Petroleum Industries

It is anticipated that geomembranes will also contribute to the expansion of the mining and petroleum industries. These industries require a robust and long-lasting lining system to contain waste and prevent environmental contamination. Geomembranes offer an efficient solution for these needs.

Potential Regulation Changes

Several nations are considering or have already implemented stringent waste management regulations, which could affect the geomembranes market. The European Union, for instance, has implemented the Circular Economy Package, which seeks to reduce waste and promote sustainable solutions. Similarly, the United States Environmental Protection Agency (EPA) has issued regulations requiring the use of geomembranes for the containment of coal ash in impoundments. Market participants in geomembranes need to monitor such developments to remain compliant and competitive.

Biodegradable geomembranes are gaining traction in the marketplace

Biodegradable geomembranes are gathering traction as a potentially disruptive technology on the market. These membranes are designed to degrade naturally, thereby reducing plastic refuse accumulation. If extensively adopted, this technology could disrupt the market, forcing incumbents to innovate and adapt.

Potential Disruptors

The increasing availability of alternative lining materials such as concrete, asphalt, and clay poses a threat to the geomembranes market. In addition, the presence of counterfeit goods could undermine the integrity and reputation of the market. Awareness of these potential market disruptors is essential for geomembrane market participants to maintain their competitiveness and adaptability.

Restraining Factors

Initial Capital Expenditures and Installation Fees

Geomembranes are a sustainable remedy to several environmental issues. However, the costly initial investment and installation costs associated with geomembranes prevent their widespread application. The price of high-quality geomembranes is relatively costly, and installation costs increase based on the engineering and design of the installation site. In addition, the cost of installing geomembranes is substantially higher than that of installing asphalt or concrete. However, sustainable environmental practices promoted by government policies may present new opportunities for manufacturers of geomembranes.

Material Scarcity Restricts

Geomembranes are composed of several basic materials that are relatively scarce and inaccessible in all regions, limiting their widespread application. The price of geomembranes is significantly affected by the availability of basic materials. When the raw materials needed to make geomembranes are limited, their prices can skyrocket, driving up production costs. As a result, manufacturers resort to alternative materials, which compromises product quality and diminishes their competitive advantage. Investing strategically in the distribution channels for primary materials could be a viable solution to this problem.

The challenge posed by Strict Environmental Regulations

In a global community where environmental conservation is a top priority for all stakeholders, the geomembranes market is subject to stringent regulations and environmental protection measures. The cost and time required to comply with these regulations can be substantial and contribute to the overall production cost. In some cases, projects that necessitate geomembranes do not get permits due to environmental concerns. Manufacturers could collaborate with environmental regulators to ensure their products satisfy established standards, thereby increasing the acceptance and uptake of their products across multiple industries.

Alternatives' rivalry is detrimental.

Intense competition from alternative solutions such as asphalt and concrete makes it more difficult for geomembranes to acquire traction on the market. However, these alternatives have several drawbacks. For instance, they may increase greenhouse gas emissions, runoff pollution, and the destruction of natural features. As a result, governments and regulators around the globe are attempting to limit the use of asphalt and concrete in favor of environmentally sustainable alternatives like geomembranes.

By Raw Material Analysis

Geomembranes market extraordinary impermeable liners that find widespread use in numerous industries to prevent the permeation of fluids or gases through the soil. High-density polyethylene (HDPE), a thermoplastic polymer with exceptional mechanical properties, durability, and resistance to UV radiation, chemicals, and punctures, dominates the market. Due to their remarkable properties and simplicity of installation, HDPE geomembranes have found widespread use as landfill liners, in mining, for water management, and in other industrial applications.

Over the next few years, geomembranes market is anticipated to expand significantly, primarily due to the worldwide emphasis on environmental protection and sustainability. Due to increased infrastructure and development initiatives, the demand for HDPE geomembranes in emerging economies is also on the rise.

The high tensile strength, chemical resistance, and ultraviolet radiation resistance of HDPE geomembranes have made it the material of choice for a variety of industrial applications, as well as the changing attitudes and behaviors of consumers. In addition, its simple installation has made it a popular choice among customers. Due to their dependability and properties, there has been an increase in the use of HDPE geomembranes in the construction and infrastructure industries.

By Technology Analysis

The most common method of manufacturing geomembranes is extrusion, which involves forcing a material, typically a thermoplastic, through a die to create a continuous shape. The procedure is efficient, cost-effective, and capable of producing geomembranes of varying thicknesses and dimensions.

Due to its affordability and effectiveness in producing geomembranes, extrusion technology has garnered traction on the market. The ability to manufacture geomembranes with varying thicknesses makes it an attractive option for consumers. Customers' preference for geomembranes with superior mechanical properties and dependability has increased the use of extrusion technology in their production.

Due to its efficacy and cost-effectiveness in producing liners of varying thicknesses, extrusion technology is widely used in the geomembranes market. Geomembranes produced by extrusion have superior mechanical properties and durability compared to geomembranes produced by other methods. The increasing emphasis on infrastructure development and environmental protection projects worldwide has increased the demand for the extrusion geomembranes market, which is anticipated to fuel the market's growth in the coming years.

By Application Analysis

The Geomembranes market is dominated by waste management, with the use of geomembranes in waste management applications on the rise. The global emphasis on environmental protection and sustainability has led to an increase in waste management sector investment. Geomembrane liners are indispensable in waste management applications such as landfills, hazardous waste containment, and industrial waste management due to their vital role in preventing environmental pollution. As a result, demand for geomembranes market in the waste management sector is anticipated to increase considerably in the coming years, driving market expansion.

The rising demand for water management and infrastructural development has generated a substantial market opportunity for geomembranes market. Included in the applications of geomembranes for water management are irrigation canals, reservoirs, and water containment systems. The expansion of the construction industry and investments in infrastructure projects have contributed to the increasing demand for geomembranes in the water management industry.

Geomembranes are now an indispensable component of contemporary construction and infrastructure initiatives. Due to their resilience and resistance to severe environmental conditions, their use in tunnels, bridges, and other essential infrastructure projects has increased. In addition, geomembranes are utilized in mining applications to prevent soil and groundwater contamination, ensuring environmental protection and sustainability.

Key Market Segments

By Raw Material

- High-density polyethylene (HDPE)

- Low-density polyethylene (LDPE)

- Ethylene propylene diene monomer (EPDM)

- Polyvinyl chloride (PVC)

- Polypropylene (PP)

- Others

By Technology

- Extrusion

- Calendaring

- Others

By Application

- Water Management

- Waste Management

- Mining

- Tunnel Liners

- Civil Engineering

- Others

Growth Opportunity

Demand for Geomembranes in Emerging Economies Is Growing.

As emerging economies rapidly urbanize and industrialize, the demand for innovative infrastructure initiatives is on the rise. Geomembranes are experiencing a rise in demand as a result of a growing population and a greater need for pure water and waste management systems. These ultramodern membranes are utilized extensively in the construction of a variety of facilities, including landfills, effluent treatment plants, and reservoirs. The use of geomembranes in these applications reduces the risk of leakage and contamination, making them an industry-leading and favored option.

The rapidly expanding use of geomembranes in transportation infrastructure

Due to the escalating trend of globalization and commerce, the transport infrastructure sector is experiencing a massive boom. The use of geomembranes for drainage systems, embankment protection, and erosion control is required for the construction of highways, bridges, and airports. Due to their exceptional resistance to severe weather conditions, ultraviolet radiation, and other environmental factors, geomembranes are ideal for transportation infrastructure projects. Therefore, the use of geomembranes in transportation infrastructure is increasing rapidly.

Materials and manufacturing technology advancements pave the way for cost-effective and long-lasting solutions.

The current era of technological advances in material science and manufacturing has resulted in an influx of economical and more resilient geomembranes. Innovative polymers and additives have facilitated the creation of high-performance geomembranes with enhanced tensile strength, elongation, and penetration resistance. In addition, technological advancements in manufacturing have considerably decreased the cost of producing geomembranes, making them more affordable and accessible to industries.

Expanding Geomembrane Applications in the Mining and Petroleum Industries

Due to geomembranes' high chemical resistance and durability, the mining and petroleum industries are among the largest consumers. These industries employ geomembranes in a variety of applications, including tailings ponds, evaporation ponds, and chemical storage structures. These applications require geomembranes that can withstand harsh chemicals and elevated temperatures. The unmatched chemical resistance and durability of geomembranes make them the material of choice for the mining and petroleum industries, resulting in a growing demand for geomembranes in these industries.

Latest Trends

The Prosperous Geomembranes Industry

The field of geomembranes is in a constant state of evolution, which is reflected in market trends. Several factors are presently influencing the market for geomembranes and its growth trajectory. HDPE geomembranes are acquiring popularity due to their exceptional chemical resistance and durability. Simultaneously, PVC geomembranes are gaining popularity in applications for waste management and water management. Using geomembranes' waterproofing properties for building foundations and green roofs, the construction industry also contributes to the growth of the geomembranes market. In addition, there is a growing demand for geomembranes with enhanced penetration resistance and elongation properties. All of these factors are propelling the market for geomembranes towards unprecedented expansion.

Durability of HDPE Geomembranes

Due to their exceptional durability, chemical resistance, and UV radiation resistance, HDPE geomembranes are attracting a great deal of attention in the market. This thermoplastic material has an exceptional strength-to-weight ratio, making it an excellent option for a variety of applications. Common applications for HDPE geomembranes include landfill liners, mining operations, containment systems, and wastewater treatment plants. Due to their superior perforation and chemical resistance, they are an ideal choice for these crucial applications.

Unique Properties of PVC Geomembranes

Thanks to their resistance to chemicals, punctures, and tears, PVC geomembranes have become the material of choice for waste management and water management applications. These exceptional characteristics make them an ideal lining material for ponds, reservoirs, and transfer stations. Low permeability and high durability make PVC geomembranes an excellent choice for applications requiring the uttermost dependability.

Geomembranes' Crucial Role in the Construction Industry

With their exceptional waterproofing properties, geomembranes are transforming the construction industry. They are an essential component of foundations and waterproofing solutions. They are ideal for below-grade applications such as foundation walls and slabs due to their adaptability and flexibility. Additionally, they are ideal for waterproofing green roofs and plaza platforms. The construction industry is embracing geomembranes as a dependable solution for a variety of waterproofing issues.

Demand for High-Performance Geomembranes Is Growing

The increasing demand for high-performance geomembranes is being driven by the need for enhanced protection against severe environments. Higher puncture resistance enables geomembranes to withstand the impact of sharp objects and debris, thereby preventing injury to the geomembrane. In addition, greater elongation properties allow geomembranes to stretch without separating, thereby providing an additional layer of protection. These characteristics are necessary for geomembranes to withstand the rigors of various applications and satisfy the market's expanding demands.

Regional Analysis

Europe Dominates with a 39% Market Share

Europe has dominated the business segment for many years, and its sustained dominance is due to its possession of the most advanced technology and resources. North America has an unrivaled advantage over other continents due to the availability of highly skilled labor, cutting-edge technology, and substantial financing, which has a significant impact on market complexity.

In addition, the vast number of large and small-scale manufacturers in the United States alone presents a formidable obstacle for other continents endeavoring to compete with North America's business sector. In addition, North America's infrastructure is unrivaled, fostering the growth of innovative, development-focused businesses. These companies, including those with thousands of employees, are the reason why North America is projected to have the largest market share during the forecast period, and this only adds to the market's complexity.

The success of the business segment in North America can be attributed to a variety of factors. North America's continued dominance in the business sector is largely attributable to the availability of a robust infrastructure, favorable government regulations, a qualified workforce, and cutting-edge technology. A vast network of established organizations, educational institutions, and funding sources has added another layer of complexity to a creative and diverse community that thrives on innovation and expansion.

In addition, North America is home to a vast number of corporations and start-ups devoted to delivering high-quality goods and services, further complicating the market. The innovation-driven competition among these businesses has moved North America to become the global leader in this business segment, adding to the market's already high degree of volatility.

Key Regions and Countries

North America

- The US

- Canada

- Rest of North America

Europe

- Germany

- France

- The UK

- Spain

- Netherlands

- Russia

- Italy

- Rest of Europe

Asia-Pacific

- China

- Japan

- Singapore

- Thailand

- South Korea

- Vietnam

- India

- New Zealand

- Rest of Asia Pacific

Latin America

- Mexico

- Brazil

- Rest of Latin America

Middle East & Africa

- Saudi Arabia

- South Africa

- UAE

- Rest of Middle East & Africa

Key Players Analysis

Geomembranes, a formidable and essential tool for geotechnical applications, have gained immense prominence due to their unparalleled characteristics of flexibility, exceptional strength, and remarkable chemical resistance. The continuous development of the geomembranes market can be credited to the escalating demand for optimal utilization of natural resources and the ever-growing number of environmental regulations that necessitate the adoption of these sophisticated membranes.

The geomembrane market is dominated by a plethora of key players, such as Solmax, GSE Environmental, AGRU America, and Nilex Inc., whose comprehensive range of geomembrane products cater to diverse applications such as landfills, mining, and water storage.

Solmax, the foremost leader in the geomembranes market, has an extensive global presence with manufacturing facilities sprawled across Canada, the US, Malaysia, Egypt, Brazil, and Chile. The company proffers high-quality polyethylene, polypropylene, and PVC geomembranes that cater to multifarious industries, including waste management, water management, and mining.

GSE Environmental is a behemoth that provides a vast range of geosynthetic products that encompass geomembranes, geotextiles, and geosynthetic clay liners (GCLs). This titan in the industry offers customized solutions that cater to project-specific requirements and has manufacturing facilities stationed in the US, Germany, Thailand, and China.

AGRU America, a paramount supplier of HDPE and LLDPE geomembranes, provides solutions to various industrial applications. The company is renowned for its superior technical support and exceptional quality products that set the benchmark for excellence.

Nilex Inc., the quintessence of excellence, specializes in the design and installation of geosynthetic products, including geomembranes, geotextiles, and erosion control products. Nilex Inc. offers bespoke solutions that cater to a wide spectrum of industries such as landfill, mining, oil and gas, and other industrial applications.

Market Key Players

- GSE Environmental LLC

- Agru America Inc.

- Solmax International Inc.

- Nilex Inc.

- Carthage Mills

- NAUE GmbH & Co. KG

- Officine Maccaferri S.p.A.

- Geofabrics Australasia Private Limited

- Carlisle Syntec Systems

- Huifeng Geosynthetics.

Recent Development

- In 2023, GSE Environmental introduced GSE LiteEarth an EPDM and synthetic turf geomembrane that is designed to be used as a green roof, landscaping, and various other environmental applications.

- In 2023, SOLMAX a producer of polyethylene geomembranes has disclosed that the company has reached an agreement with Koninklijke Ten Cate to acquire TenCate Geosynthetics.

- In 2023, 3V Sigma USA will offer a wide variety of leading products including Antioxidants, HALS, UV Absorbers, and Optical Brighteners used in chemical solutions for the Geomembrane & Geosynthetic Market.

Report Scope

Report Features Description Market Value (2023) USD 3.7 Bn Forecast Revenue (2033) USD 6.8 Bn CAGR (2024-2033) 6.4% Base Year for Estimation 2023 Historic Period 2016-2023 Forecast Period 2024-2033 Report Coverage Revenue Forecast, Market Dynamics, COVID-19 Impact, Competitive Landscape, Recent Developments Segments Covered By raw material: High-density polyethylene (HDPE), Low-density polyethylene (LDPE), Ethylene propylene diene monomer (EPDM), Polyvinyl chloride (PVC), Polypropylene (PP), Others

By technology: Extrusion, Calendaring, Others

By application: Water Management, Waste Management, Mining, Tunnel Liners, Civil Engineering, OthersRegional Analysis North America – The US, Canada, & Mexico; Western Europe – Germany, France, The UK, Spain, Italy, Portugal, Ireland, Austria, Switzerland, Benelux, Nordic, & Rest of Western Europe; Eastern Europe – Russia, Poland, The Czech Republic, Greece, & Rest of Eastern Europe; APAC – China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Malaysia, Philippines, Singapore, Thailand, Vietnam, & Rest of APAC; Latin America – Brazil, Colombia, Chile, Argentina, Costa Rica, & Rest of Latin America; Middle East & Africa – Algeria, Egypt, Israel, Kuwait, Nigeria, Saudi Arabia, South Africa, Turkey, United Arab Emirates, & Rest of MEA Competitive Landscape GSE Environmental LLC, Agru America Inc., Solmax International Inc., Nilex Inc., Carthage Mills, NAUE GmbH & Co. KG, Officine Maccaferri S.p.A., Geofabrics Australasia Private Limited, Carlisle Syntec Systems, Huifeng Geosynthetics. Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) -

-

- GSE Environmental LLC

- Agru America Inc.

- Solmax International Inc.

- Nilex Inc.

- Carthage Mills

- NAUE GmbH & Co. KG

- Officine Maccaferri S.p.A.

- Geofabrics Australasia Private Limited

- Carlisle Syntec Systems

- Huifeng Geosynthetics.