Coordinate Measuring Machine Market By Type (Fixed, Bridge, Cantilever, Others), By Application (Quality Control & Inspection, Reverse Engineering, Others), By end-use Industry (Aerospace & Defense, Automotive, Medical, Electronics, Energy & Power, Others), By Region And Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, And Forecast 2023-2032

-

9590

-

March 2023

-

158

-

-

This report was compiled by Kalyani Khudsange Kalyani Khudsange is a Research Analyst at Prudour Pvt. Ltd. with 2.5 years of experience in market research and a strong technical background in Chemical Engineering and manufacturing. Correspondence Sr. Research Analyst Linkedin | Detailed Market research Methodology Our methodology involves a mix of primary research, including interviews with leading mental health experts, and secondary research from reputable medical journals and databases. View Detailed Methodology Page

-

Quick Navigation

Report Overview

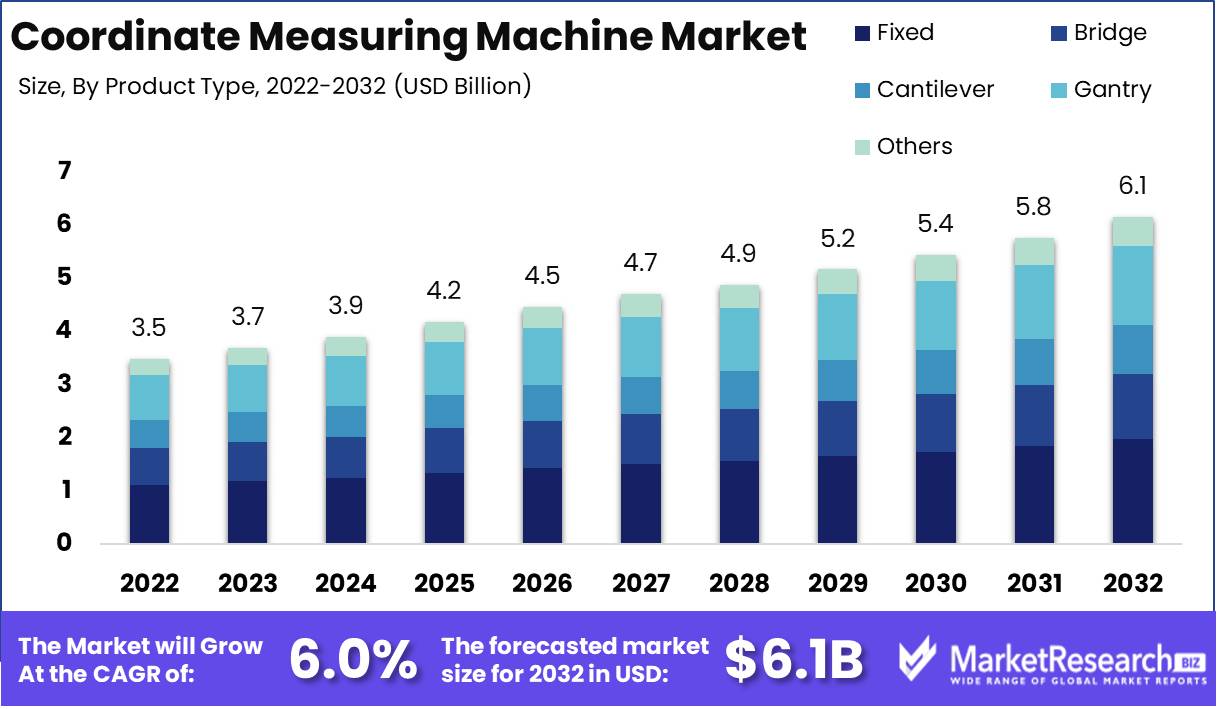

Coordinate Measuring Machine Market size is expected to be worth around USD 6.1 Bn by 2032 from USD 3.5 Bn in 2022, growing at a CAGR of 6.0% during the forecast period from 2023 to 2032.

The report on the coordinate measuring machine market provides a comprehensive analysis of market trends, growth opportunities, and industry challenges. This segmentation includes classification, application, end-user, and region. In addition, the report provides profiles of market leaders and details on their business strategies, product offerings, and financial performance.

Coordinate Measuring Machine Market is a device that accurately and precisely measures the geometric properties of objects. It is used to create a three-dimensional model of an object that can be compared to the design specification. The CMM operates by measuring the distance between coordinates on an object by moving a sensor along the x, y, and z axes.

A CMM's primary purpose is to ensure that an object conforms to the required specifications and tolerances. It can measure an object's dimensions, angles, and contours, among other attributes. Aerospace, automotive, and medical industries, among others, use CMMs to assure the quality and precision of their products.

The significance of CMMs resides in their ability to accurately and precisely measure objects. This ensures that the product satisfies the necessary specifications and tolerances, which is essential in industries such as aerospace and medicine. In addition to their high accuracy, ability to measure complex geometries, and nondestructive nature, CMMs have a number of advantages over other measuring devices.

Recent years have witnessed numerous noteworthy innovations on the CMM market. The introduction of portable CMMs is among the most significant innovations. These devices enable on-site measurement, which is crucial for industries such as the automotive and aerospace sectors. Utilizing laser scanning technology permits the rapid and precise measurement of intricate shapes.

Driving factors

Technological Progress and Rising Demand

In this era of rapid technological advancement, Coordinate Measuring Machine Market is experiencing a surge in demand. These devices have attained unprecedented levels of precision and efficiency as a result of ground-breaking innovations, attracting the attention of various industries seeking superior measurement solutions.

Impact of Globalization on Precise Measurement

As globalization extends its wings, the demand for CMMs rises, driven by the imperative need to meet the stringent requirements of international clients. With a focus on precise measurement, the manufacturing industry has emerged as a key player, pursuing quality control and consistency throughout their production procedures.

The Development of Non-Contact Measurements

In recent years, non-contact measurement solutions have captured the imagination of the industry due to their unparalleled flexibility and precision. In excess of conventional contact-based methods, these innovative alternatives have provoked a skyrocketing demand for coordinate measuring machine market with revolutionary non-contact measurement capabilities.

Three-dimensional printing

The introduction of 3D printing technology has had a positive impact on the coordinate measuring machine market, opening up a universe of limitless manufacturing possibilities. This ground-breaking innovation has triggered a surge in demand for CMMs capable of measuring and verifying the intricate details of 3D-printed objects, thereby accelerating the market's growth trajectory.

Statutes and Potential Effects

Currently, there are no significant regulatory changes that could potentially disrupt the CMM market. Nonetheless, vigilance is required, as the introduction of new regulations pertaining to precision measurement equipment may have unanticipated effects on the market's future trajectory.

Prospects for AI, Robotics, and the Future

The advent of Artificial Intelligence (AI) and Robotics represents a tremendous opportunity for the coordinate measuring machine market. Pioneering these technologies is anticipated to unleash unprecedented efficiency and automation in measurement processes, catapulting the industry into a new epoch of progress.

Changing consumer conduct

The swift transformation of consumer behavior is likely to leave an indelible imprint on the future of the CMM market. The increasing demand for customization and personalization creates a need for CMMs with unrivaled flexibility and precision to meet the measurement requirements of unique and diverse objects.

Restraining Factors

Compatibility Restricted with Certain Materials and Forms

The limited compatibility of the Coordinate Measuring Machine market with certain materials and dimensions is one of its major obstacles. Coordinate measuring devices typically rely on physical contact to measure the dimensions of objects; therefore, they cannot measure soft or deformable materials. CMMs have difficulty measuring undercuts, inclined surfaces, and freeform geometries. Therefore, manufacturers and other organizations that require precision measurement data for manufacturing, quality control, or reverse engineering must seek out alternative solutions or technologies that can accommodate these dimensions and materials.

Technicians with Expertise Required for Data Operation and Interpretation

Another factor restraining Coordinate Measuring Machine Market is the need for qualified technicians or engineers to operate these CMMs, acquire data, and accurately interpret the results. Typically, coordinate measuring devices require a high level of technical expertise, calibration, and programming skills, which are not readily available on the market. In addition, personnel operating or programming CMMs typically require additional training, certifications, or qualifications to guarantee data quality and machine dependability.

Slow Speed of Measurement and Processing

The sluggish measurement speed and processing time of coordinate measuring machine market is an additional significant factor that hinders its adoption and use in a variety of industries. Typically, it requires a substantial amount of time for these machines to acquire data and measurements, calibrate, and then process that data into usable information. Therefore, coordinate measuring devices are restricted to applications that do not require real-time measurements or rapid scanning rates. Consequently, businesses require quicker and more responsive technologies that can deliver real-time measurement data, particularly in industrial settings.

Reduced mobility and adaptability in the workplace

Another obstacle impeding the expansion of the CMM market is the limited mobility and adaptability of Coordinate Measuring Machine Market in the workplace. CMMs are typically hefty and cumbersome, necessitating dedicated floor space. As a consequence, they are not cost-effective for small enterprises and cannot be moved or repositioned without difficulty. In addition, CMMs require controlled environmental conditions, such as temperature and humidity, which further restricts their mobility and flexibility in the workplace.

Type Analysis

Fixed Segment dominates The Coordinate Measuring Machine Market In the realm of manufacturing, measuring and inspection are essential to ensuring the integrity of the final product. In this regard, Coordinate Measuring Machine Market performs an important role. The CMM market has been divided into numerous segments, with the Fixed Segment being one of the most prevalent. The Fixed Segment is utilized primarily for measuring small to medium components in a stable environment where precision is crucial. This variety of coordinate measuring machine market is predominantly employed for dimensional and geometrical measurements, quality control, and inspection.

Consumers desire high-quality goods, which necessitates the use of precise measurement and inspection apparatus. The Fixed Segment's high precision, consistency, and repeatability make it an ideal solution for quality control and inspection. This form of CMM has acquired popularity due to its ability to reduce costs and boost productivity. The Fixed Segment can be programmed to perform routine tests, ensuring that product quality is continuously enhanced. Therefore, consumers are employing the Fixed Segment because it provides accurate and repeatable measurement results.

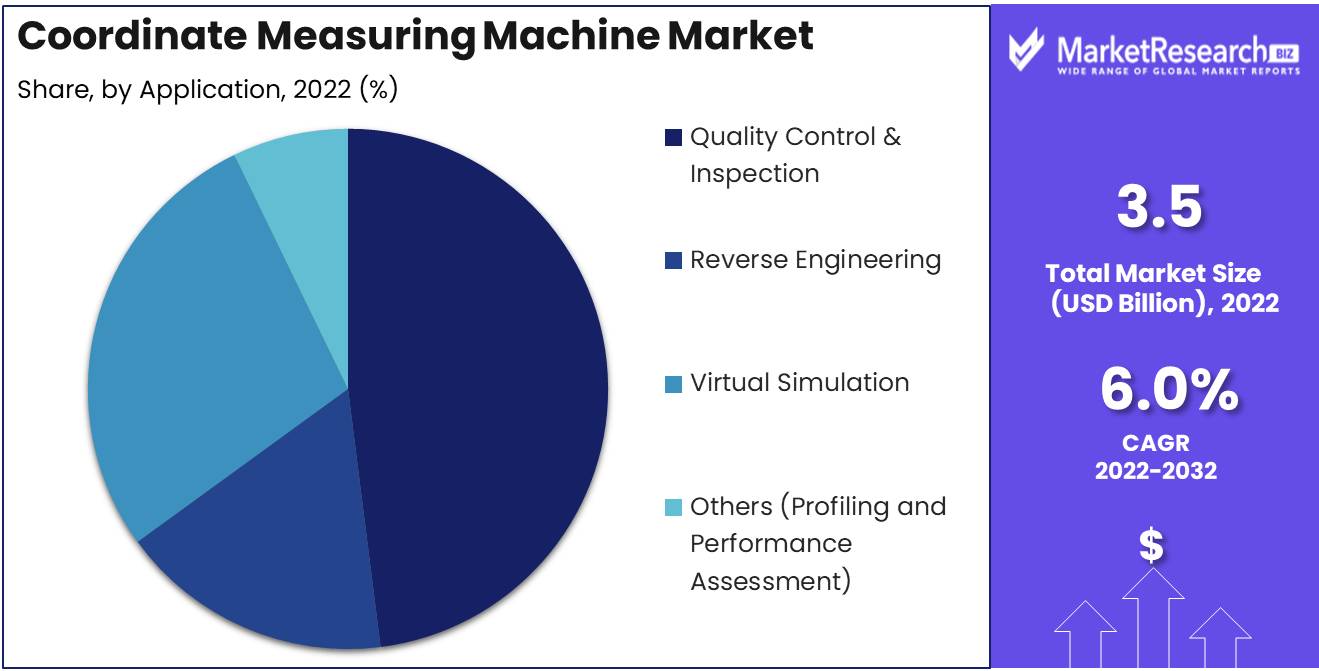

Application Analysis

Quality Control and Inspection Segment dominates the Coordinate measuring machine market. Quality control and verification dominates Coordinate Measuring Machine Market (CMM). This type of CMM is utilized primarily for measuring components to ensure that they conform to the required specifications. The segment of quality control and inspection provides high precision, dependability, and repeatability, making it an indispensable instrument for the aerospace, automotive, and medical industries, among others. The quality control and inspection segment aids manufacturers in attaining the desired level of quality, which is crucial in today's competitive global market.

Consumers are demanding higher quality products, which necessitates the use of precise measuring and inspection apparatus. The segment of quality control and inspection offers high accuracy, dependability, and repeatability, making it essential for businesses in the present day. Before releasing the final product to the market, manufacturers are able to swiftly identify and rectify any quality issues if they have access to effective measurement and inspection tools. As a result, consumers are employing the quality control and inspection sector as a solution for ensuring the quality of products.

End-Use Industry Analysis

The Electronics Segment dominates Coordinate Measuring Machine Market. As a result of its high accuracy, dependability, and efficiency, the electronics segment dominates the CMM market. The electronics segment, also known as the DCC (Direct Computer Control), has a probe affixed to the machine's head that measures the component as it travels across it. The DCC is more flexible than the Fixed Segment because it can measure complex components and acquire a large number of points in less time. This form of CMM is commonly used in industries where precision and quality are of the utmost importance, such as aerospace, automotive, and medicine.

Consumers are increasingly interested in purchasing high-quality goods, and the electronics industry assists manufacturers in meeting this demand. This form of CMM offers high precision and speed, making it ideal for the rapid inspection of complex components. As a result of its capacity to acquire a large number of points in a brief amount of time, the electronics segment has garnered popularity for large-scale production. Therefore, consumers are employing this form of CMM because it is a time- and cost-saving solution.

Key Market Segments

By Type

- Fixed

- Bridge

- Cantilever

- Gantry

- Others (Portable, Articulated Arm, Handheld)

By Application

- Quality Control & Inspection

- Reverse Engineering

- Virtual Simulation

- Others (Profiling and Performance Assessment)

By End-use Industry

- Aerospace & Defense

- Automotive

- Medical

- Electronics

- Energy & Power

- Heavy Machinery

- Others (Education, Forensics, Fashion and Jewelry, and Research)

Growth Opportunity

Development in Emerging Markets

As the manufacturing sector expands internationally, so does the CMM market. This industry's development potential is not restricted to developed nations. CMM manufacturers have enormous potential in emergent markets such as China, India, and other developing nations. Emerging markets are experiencing a rapid expansion of the manufacturing sector, necessitating a substantial demand for CMM devices. By entering these markets, manufacturers can establish a much larger customer base, thereby spurring market expansion.

Improving Accuracy and Precision

Precision is not an added advantage in the modern world; it is a necessity. The demand for CMM devices with superior precision and accuracy has skyrocketed. Precision and exactness are crucial determinants of the quality of manufactured goods. Technology advancements have allowed us to design CMM devices with greater precision and accuracy than ever before. By concentrating on enhancing these characteristics, we can obtain a competitive advantage and attract new consumers.

Integration of Intelligent Technology

The rise of intelligent technology has had a profound effect on numerous industries, including CMM manufacturing. Integrating intelligent technologies into CMM machines increases productivity and effectiveness. Within seconds, these devices can now conduct a variety of complex tasks. Combining intelligent technologies with CMM machines enables manufacturers to operate more efficiently, resulting in increased revenue and productivity.

Developing Industry-Specific Tailored Solutions

The demand for customized solutions is emerging as a major industry growth driver. Each industry has specific needs that cannot be satisfied by a one-size-fits-all solution. Manufacturers of CMM machines can leverage on this opportunity by developing industry-specific solutions. The industry-specific tailoring of the solutions provides a competitive advantage and promotes market expansion.

Enhancing Partnerships with Distributors and Suppliers

Strengthening relationships with suppliers and distributors is essential for expanding reach and boosting revenue. Manufacturers and suppliers/distributors have a symbiotic relationship. Suppliers and distributors receive improved pricing, access to a larger customer base, and more efficient operations, while manufacturers enjoy an expansion of their market reach and revenue. By establishing and strengthening alliances with suppliers and distributors, manufacturers can leverage their expertise to reach a broader audience and fuel growth.

Latest Trends

Automotive and Aerospace Industries

The expanding use of CMMs in the aerospace and automotive industries is one of the most significant market trends in the CMM sector. The need for precise and reproducible measurements on complex components, such as engine elements and airframe structures, is driving this development. CMMs are crucial to preserving the safety and dependability of aircraft and automobiles, as well as to ensuring that these components adhere to strict tolerances and specifications.

High expansion potential

Emergence of new markets with high growth potential for CMMs is an additional significant development. For instance, the industry for medical devices is expanding rapidly due to the rising demand for minimally invasive surgical techniques. Consequently, there is a developing demand for CMMs and other high-precision measurement technologies. Additionally, the production of wind turbines and solar panels is increasingly utilizing CMMs in the renewable energy industry.

Facilitating Industrial Automation

Governments throughout the globe are progressively recognizing the significance of manufacturing automation and implementing initiatives to support the sector. The Make in India initiative of the Indian government, for instance, seeks to encourage domestic manufacturing and promote foreign investment in the industry. This has led to a rise in the adoption of automation and quality control technologies like CMMs.

Miniaturization within the Electronics Business

The continuing trend towards miniaturization in the electronics industry is another significant market trend. As the size and complexity of electronic devices continue to shrink and increase, the demand for highly accurate and precise measurement technologies grows. CMMs are increasingly utilized to measure the minuscule components used in devices like smartphones and wearable technology.

Automated Processes for Inspection

Increasing awareness of the advantages of automated inspection processes drives the expansion of the CMM industry. CMMs are becoming increasingly essential for assuring the quality and consistency of products as businesses seek to automate their manufacturing processes. With the ability to measure complex geometries swiftly and precisely, CMMs are an indispensable instrument for any business that wishes to remain competitive in the current market.

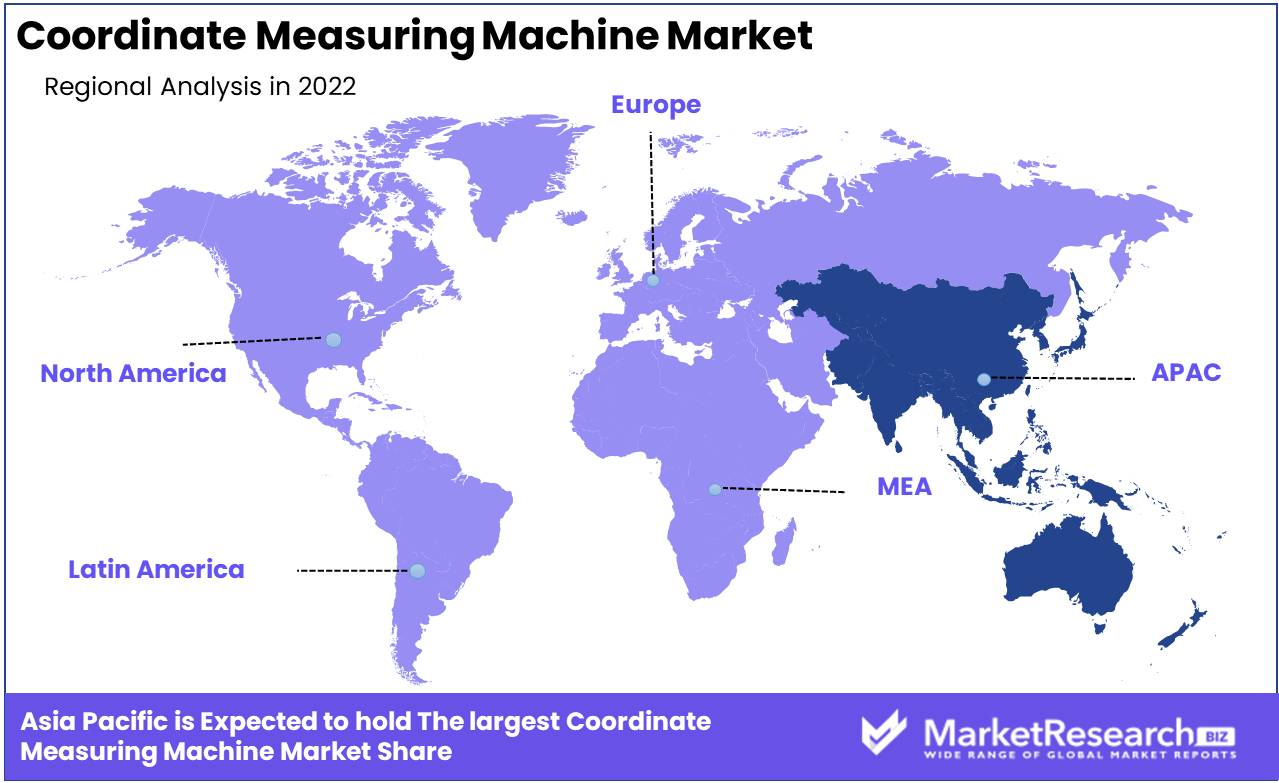

Regional Analysis

Asia-Pacific is currently the largest and fastest-growing market in the globe. It has become a global leader in terms of population, economic expansion, and technological development. The region's consistent development has made it an attractive location for international investors.

The Asia-Pacific region is home to more than four billion individuals, or 56 percent of the world's population. The region's population has consistently increased over the past few decades, making it the most populous region in the globe. A substantial proportion of Asia's population is under 30 years old, which is an added advantage. This demographic advantage is vital for generating innovation, fostering entrepreneurship, and sustaining economic growth in the years to come.

Growth in the Asia-Pacific region has been predominantly propelled by urbanization, an expanding middle class, and technological innovation. Urbanization has been a significant factor, with cities providing substantial economic opportunities and propelling economic growth. Consumption has been largely driven by the expanding middle class, which has created new markets and opportunities for businesses worldwide. China, South Korea, Japan, and India are the world's leaders in adopting new technologies, and their technological innovation has contributed significantly to the region's growth.

Despite its positive development trajectory, the Asia-Pacific region confronts significant obstacles as the global economy transitions to one that is sustainable and inclusive. Climate change is a pressing issue in the region, as natural disasters are occurring more frequently and sea levels are rising, resulting in significant economic losses. Numerous nations in the region continue to rely on fossil fuels, which contributes to environmental degradation. Social inequality and political instability must be addressed if the region is to achieve long-term prosperity.

Key Regions and Countries

North America

- US

- Canada

- Mexico

Western Europe

- Germany

- France

- The UK

- Spain

- Italy

- Portugal

- Ireland

- Austria

- Switzerland

- Benelux

- Nordic

- Rest of Western Europe

Eastern Europe

- Russia

- Poland

- The Czech Republic

- Greece

- Rest of Eastern Europe

APAC

- China

- Japan

- South Korea

- India

- Australia & New Zealand

- Indonesia

- Malaysia

- Philippines

- Singapore

- Thailand

- Vietnam

- Rest of APAC

Latin America

- Brazil

- Colombia

- Chile

- Argentina

- Costa Rica

- Rest of Latin America

Middle East & Africa

- Algeria

- Egypt

- Israel

- Kuwait

- Nigeria

- Saudi Arabia

- South Africa

- Turkey

- United Arab Emirates

- Rest of MEA

Key Players Analysis

Several key competitors on the global coordinate measuring machine market are continually innovating and introducing new technologies to remain ahead of the competition. Hexagon AB, Carl Zeiss AG, Mitutoyo Corporation, Nikon Corporation, Keyence Corporation, Renishaw plc, Wenzel Group GmbH & Co. KG, Tokyo Seimitsu Co. Ltd., Faro Technologies Inc., and Aberlink Ltd. are among the market leaders.

Hexagon AB is a prominent provider of hardware, software, and services for metrology. The company's coordinate measuring devices feature high-precision measurement capabilities and are suitable for a variety of industries, including the aerospace, automotive, and medical sectors.

Carl Zeiss AG is well-known for its sophisticated optical technologies and is a significant player in the coordinate measuring machine market. CMMs manufactured by the company are designed to deliver precise measurement results even in severe industrial environments, making them ideal for use in the automotive and aerospace industries.

Mitutoyo Corporation is a Japanese corporation specializing in precision measuring instruments, such as coordinate measuring machines (CMMs). The company's CMMs are renowned for their high accuracy, dependability, and user-friendliness, and they are used in a wide range of industries, including automotive, aerospace, medical, and research.

Another Japanese company, Nikon Corporation, is a prominent manufacturer of CMMs that provide high-speed scanning, accuracy, and usability. Popular in the automotive and aerospace industries, as well as the manufacturing sector, are the company's products.

Top Key Players in Coordinate Measuring Machine Market

- Hexagon AB

- FARO Technologies, Inc.

- Nikon Corporation

- Keyence Corporation

- Carl Zeiss AG

- Mitutoyo Corporation

- Perceptron, Inc.

- Creaform, Inc.

- International Metrology Systems

- Metronor AS

- Trimek, S.A.

- Applied Automation Technologies, Inc.

Recent Development

In 2021, This software update for CMMs includes over 60 new functions and improvements, which lead to significantly better performance in quality control. With improved mathematical algorithms and other innovations, the measurement results are now available 20 times faster than with ZEISS CALYPSO 2020.

In 2021, This new model range of CNC video measuring systems from Nikon is suitable for inline, automated dimensional measurement. The VMZ-S4540 and VMZS6555 models feature a high-speed camera and a new software platform that allow for fast and accurate measurements.

In 2022, MMI released a new line of CMMs in 2022, the ALPHA. These machines are designed to be more user-friendly and efficient than previous models, and they feature a number of new innovations, such as a self-calibration system and a 3D touchscreen display.

In 2022, This new CMM from Mitutoyo features a number of advanced technologies, including a high-resolution laser scanner, a 6-axis probe, and a new software platform. The Crysta Apex is designed to provide high-accuracy measurements in a variety of applications.Report Scope:

Report Features Description Market Value (2022) USD 3.5 Bn Forecast Revenue (2032) USD 6.1 Bn CAGR (2023-2032) 6% Base Year for Estimation 2022 Historic Period 2016-2022 Forecast Period 2023-2032 Report Coverage Revenue Forecast, Market Dynamics, COVID-19 Impact, Competitive Landscape, Recent Developments Segments Covered By Type (Fixed, Bridge, Cantilever, Gantry, Others (Portable, Articulated Arm, Handheld))

By Application (Quality Control & Inspection, Reverse Engineering, Virtual Simulation, Others (Profiling and Performance Assessment))

By end-use Industry (Aerospace & Defense, Automotive, Medical, Electronics, Energy & Power, Heavy Machinery, Others (Education, Forensics, Fashion and Jewelry, and Research))Regional Analysis North America – The US, Canada, & Mexico; Western Europe – Germany, France, The UK, Spain, Italy, Portugal, Ireland, Austria, Switzerland, Benelux, Nordic, & Rest of Western Europe; Eastern Europe – Russia, Poland, The Czech Republic, Greece, & Rest of Eastern Europe; APAC – China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Malaysia, Philippines, Singapore, Thailand, Vietnam, & Rest of APAC; Latin America – Brazil, Colombia, Chile, Argentina, Costa Rica, & Rest of Latin America; Middle East & Africa – Algeria, Egypt, Israel, Kuwait, Nigeria, Saudi Arabia, South Africa, Turkey, United Arab Emirates, & Rest of MEA Competitive Landscape Hexagon AB, FARO Technologies, Inc., Nikon Corporation, Keyence Corporation, Carl Zeiss AG, Mitutoyo Corporation, Perceptron, Inc., Creaform, Inc., International Metrology Systems, Metronor AS, Trimek, S.A., Applied Automation Technologies, Inc. Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) -

-

- Hexagon AB

- FARO Technologies, Inc.

- Nikon Corporation

- Keyence Corporation

- Carl Zeiss AG

- Mitutoyo Corporation

- Perceptron, Inc.

- Creaform, Inc.

- International Metrology Systems

- Metronor AS

- Trimek, S.A.

- Applied Automation Technologies, Inc.