Global Bricklaying Robot Market By Automation (Fully Autonomous, Semi-Autonomous), By Application (Residential Buildings, Commercial Buildings, Other), By Region And Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, And Forecast 2023-2032

-

37700

-

June 2023

-

154

-

-

This report was compiled by Vishwa Gaul Vishwa is an experienced market research and consulting professional with over 8 years of expertise in the ICT industry, contributing to over 700 reports across telecommunications, software, hardware, and digital solutions. Correspondence Team Lead- ICT Linkedin | Detailed Market research Methodology Our methodology involves a mix of primary research, including interviews with leading mental health experts, and secondary research from reputable medical journals and databases. View Detailed Methodology Page

-

Quick Navigation

Report Overview

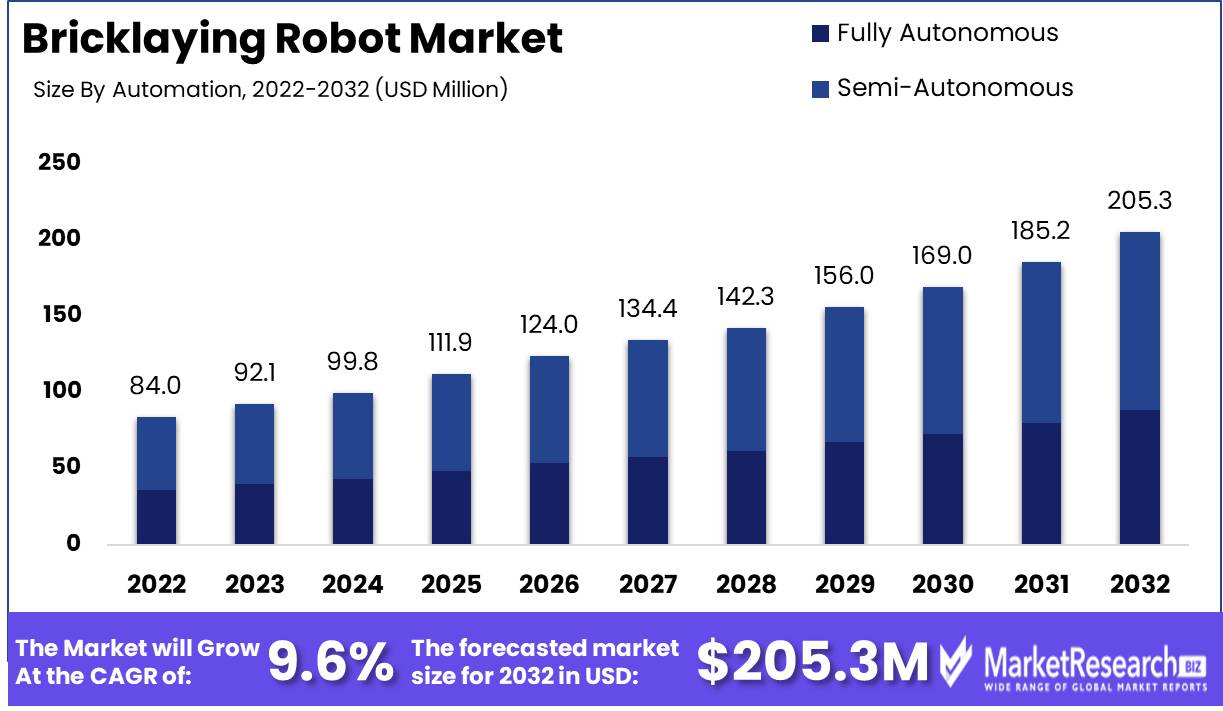

Global Bricklaying Robot Market size is expected to be worth around USD 205.3 Mn by 2032 from USD 84.0 Mn in 2022, growing at a CAGR of 9.6% during the forecast period from 2023 to 2032.

The captivating global bricklaying robot market combines cutting-edge robotics and bricklaying technologies. These awe-inspiring mechanical marvels cleverly reduce the time restrictions of bricklaying while enhancing its precision and delicacy. In the ever-changing construction industry, these bricklaying robots provide essential cost-effective solutions that transcend quality boundaries and reinvent the fabric of construction procedures.

Bricklaying robots have undergone a remarkable transformation as a result of their relentless quest for innovation, adopting a variety of new innovations that boost their efficacy and efficiency to previously unheard-of levels. A symphony of sensory upgrades is arranged within their mechanical frames to improve bricklaying precision.

These robots can easily adjust to new situations and complicated bricklaying patterns thanks to cutting-edge software. The design of these autonomous artisans has undergone a captivating metamorphosis, making them more compact and agile, like ethereal dancers gently pirouetting across the construction site.

The demand for bricklaying robots is so high that massive investments have been made in this industry. Pioneering construction enterprises have partnered with visionary robotics startups or developed in-house solutions to seamlessly incorporate robotic marvels into their broad product and service offerings.

Bricklaying robots have easily overcome convention's boundaries, making them a widespread answer. Their omnipresent presence is seen in the awe-inspiring realm of building construction, the exquisite artistry of brick paver installation, and even the prodigious realm of brick manufacture.

While the mechanical robot emerges as the primary patron of bricklaying robots, other sectors are eagerly exploring the myriad of possibilities afforded by these mechanical maestros. Brick paver installation firms have recognized the attractiveness of these sentient companions and adopted them as the ultimate solution to their specific issues.

Brickmakers have welcomed these robot allies, modernizing their craft. Government agencies have entered the realm of bricklaying robots to shape the fabric of infrastructure projects.

Despite this technological marvel, ethical issues echo through the corridors of advancement. Automation's captivating symphony has discordant tones. The biggest issue is the possible impact on the labor market, as bricklaying robots could disrupt the construction industry's traditional employment.

Driving factors

The Market for Bricklaying Robots is Driven by Growing Demand and Efficiency

The global market for bricklaying robots is likely to grow a lot in the next few years due to a number of factors. The growth of the market is likely to be helped by things like the growing need for efficient construction around the world. The growing populations and economies in many parts of the world need a construction that works well. Bricklaying robots have been made and used because of the need for faster, more accurate, and less expensive ways to lay bricks.

Due To a Lack of Skilled Workers, Bricklaying Robots are Becoming More Popular

The skilled labor lack that is experienced in different parts of the world is another factor that drives the global bricklaying robot market. Since productivity and efficiency are becoming more and more important in construction, there is a huge need for skilled masons who can work quickly and correctly. But the lack of skilled labor causes delays, lowers quality, and eventually results in increased costs. With Bricklaying Robots, construction companies can save time, cut costs, and keep quality standards high without relying on skilled labor.

Robotic Improvements Help the Bricklaying Market Work Better

Also, the growth of the Bricklaying Robot market is helped by the improvements in robotics technology. Pioneering technologies like the Internet of Things (IoT), Machine Learning, and Artificial Intelligence (AI) have made it possible for Bricklaying robots to do more complicated tasks, which has made them more efficient. Because of this increased efficiency, lead times are shorter, productivity is higher, and construction companies save money overall.

Bricklaying Robot Market Potential for Regulatory Changes

Even though there aren't many rules about how Bricklaying robots can be used in construction right now, that could change in the future. Governments may set rules to ensure the public's and workers' safety as well as the construction process's high standards. Still, these rules could give Bricklaying Robot makers a chance to improve their marketplace by coming up with new ways to meet the rules.

Drones are Changing the Way Bricklaying Robots are Watched

The use of Drones to keep an eye on Bricklaying Robot operations is one example of an emerging technology that is gaining traction. Drones can take pictures of construction sites, which lets masons and construction managers check on how the bricklaying is going from a distance. When combined with the use of Bricklaying Robots, this new idea can lead to increased output, lower labor costs, and shorter construction times.

There are Things That Could Shake Up the Bricklaying Robot Industry

The development of new technologies that can carry out Bricklaying tasks better than Robots or the availability of a cheap option for Bricklaying Robots are potential market disruptors in the Bricklaying Robot market. Changes in how people act and what they buy could also have an effect on the size and shape of the Bricklaying Robot business.

Restraining Factors

Robots are Changing the Way the Construction Industry Works

In recent years, the construction business has changed a lot. Now, robots and artificial intelligence are used all the time. Robotic technology has had a big impact on the bricklaying market by making bricklaying faster and less expensive. Bricklaying robots are in high demand right now because they work quickly and accurately. But, despite their promise, there are a few problems that make it hard to use them.

Bricklaying Robots are in Demand Because they are Fast and Accurate.

The high starting investment cost is one of the most important things that keeps people from using bricklaying robots. To buy these machines, you have to spend a lot of money, which may be hard for small construction companies to explain. There are also costs for maintenance and training, which could add even more to the price.

Costs At the Start Make it Hard to Use Robots.

But despite the beginning costs, using a bricklaying robot will save money in the long run. Robots are very effective and can do jobs much faster than people can. This advantage can save money in the long run, which could make up for the cost of the original investment. So, even though the beginning costs may be too high, the cost of being an out-of-date construction company in the future may be even higher.

Long-Term Savings Outweigh the Initial Investment.

The bricklaying market is always changing, with new styles and shapes of bricks being made all the time. But because they are so complicated, it is hard for bricklaying robots to change to new designs. This means that they might need to add more code and change their tools to work with new brick styles.

Challenges for Robots in Adapting to New Brick Designs

To deal with this problem, companies that make bricklaying robots are always making new update packages and software that makes it easier to change to new brick designs. This makes sure that the robot can work with the newest bricks and keep up with how the market is changing.

Software Updates Make it Easy to Change.

It is known that the construction business is slow to adopt new technologies. Some people in the business, who prefer traditional methods, are against bricklaying robots. Lack of information, skills, and training about how to set up and use robots is another thing that slows down their use.

The Construction Industry Has Been Slow to Adopt Robotics.

But because the business world is moving so quickly, companies can't afford to fall behind in technology. Companies that don't accept new technologies quickly risk falling behind their competitors. More and more people are seeing that using bricklaying robots has perks like speed, safety, and better work. Because of this, it is only a matter of time before a lot of companies start using this technology.

Keeping Up With Technology is Important To Stay Competitive.

Robots in general have to follow certain rules, and bricklaying robots are no different. Because these tools are often big and dangerous if they aren't well taken care of, safety rules make it hard to use them. Also, there are worries about robots taking over jobs. Some people say that using robots could lead to fewer jobs for people.

Automation Analysis

Automation has changed numerous industries, including construction. Bricklaying robots have gained popularity in recent years due to their efficiency and efficacy in building. The global bricklaying robot market has two segments: semi-autonomous and fully autonomous. The semi-autonomous segment dominates the bricklaying robot market and is expected to develop the fastest.

Due to its efficiency and flexibility in construction projects, the semi-autonomous segment of the global bricklaying robot market is growing. These bricklaying robots are controlled by humans. Due to its low investment, the semi-autonomous segment has grown.

The deployment of semi-autonomous bricklaying robots is driven by economic growth in emerging economies. Recent economic expansion in China, India, and Brazil has increased construction. The surge in construction activities has produced a desire for faster, more efficient construction processes, and semi-autonomous bricklaying robots are the appropriate solution.

Semi-autonomous bricklaying robots are popular due to their efficiency and speed. This technology saves building time and costs, attracting consumers. These robots improve building quality through consistency and accuracy.

The semi-autonomous segment is expected to grow the fastest. As emerging economies develop, construction will increase, requiring faster and more efficient ways. Construction companies will adopt the semi-autonomous segment since it's cheaper.

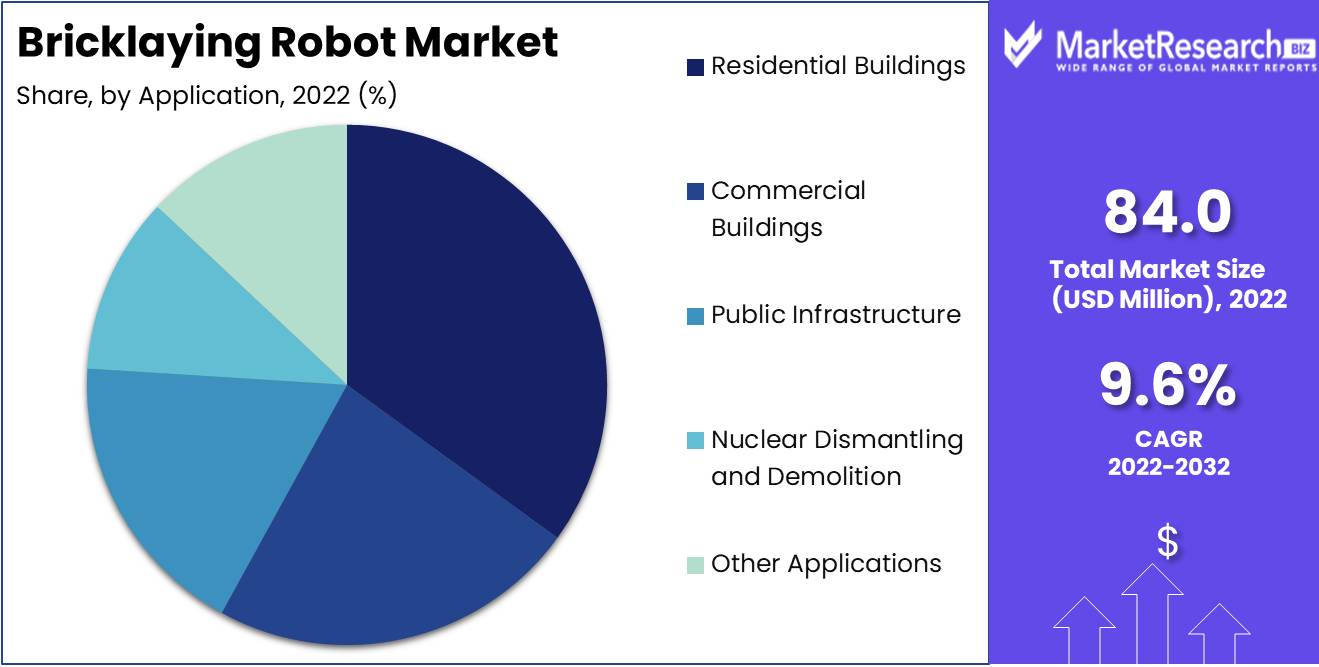

Application Analysis

Due to an increase in demand for residential projects globally, the bricklaying robot segment dominates the global building robot market. The residential buildings segment is expected to increase the fastest.

Due to rising construction activity and demand for residential structures worldwide, the residential buildings segment of the global bricklaying robot market is attracting attention. Bricklaying robots build residential buildings with accuracy and uniformity, improving quality.

The residential buildings segment is growing in emerging economies. Global residential property demand has increased due to population growth and urbanization. Due to economic growth, residential property demand is rising in developing countries, increasing construction. The introduction of bricklaying robots is a result of this demand for quicker, more affordable construction solutions.

Consumer trend and behavior toward the bricklaying robot segment has been positive, especially because of the speed and quality of bricklaying buildings. This technology saves building time and costs, attracting consumers. These robots improve building quality through accuracy and consistency.

Over the next few years, the residential buildings segment is expected to grow the most. Population growth and urbanization have driven global demand for residential properties and faster, cheaper construction alternatives. Bricklaying robots minimize building costs and improve quality through consistency, accuracy, and speed. Bricklaying robot use will increase globally in the next years in the residential building segment.

Key Market Segments

By Automation

- Fully Autonomous

- Semi-Autonomous

By Application

- Residential Buildings

- Commercial Buildings

- Public Infrastructure

- Nuclear Dismantling and Demolition

- Other Applications

Growth Opportunity

Rapid Development of Bricklaying Robots

The global market for bricklaying robots is poised for explosive growth. Bricklaying robots have become an integral part of the construction industry as a result of the transition toward automation and the rising demand for cost-effective solutions. In this report, we will examine the factors driving the growth of the bricklaying robot market and the emerging opportunities for businesses in this sector.

Economical Construction Automation

The demand for cost-effective solutions is one of the key factors driving the growth of the bricklaying robot market. Traditional methods of bricklaying require significant labor, which can be costly. By automating the bricklaying process, businesses can reduce labor costs and improve productivity. This is especially essential in markets where labor costs are high or where skilled labor is scarce.

Revolution in Bricklaying Driven by AI

Integration of AI and computer vision technologies is an additional factor driving the growth of the bricklaying robot market. Bricklaying robots equipped with these technologies can position bricks precisely and ensure that they are aligned and level. This reduces the likelihood of errors and allows construction projects to be completed more quickly and to a higher standard.

Collaboration in Robotics and Construction

Collaboration between the robotics and construction industries is also driving the market growth for bricklaying robots. By collaborating, the two industries can create solutions that are uniquely tailored to the requirements of construction projects. For instance, robots can be programmed to operate in confined or hazardous spaces, allowing for greater flexibility and productivity on construction sites.

Robot Demand Is Increased by Modular Construction

The adoption of modular construction techniques creates opportunities for the market for bricklaying robots. Prefabricated modules that can be put together on-site are used in modular construction. This method necessitates precise and accurate bricklaying, which can be accomplished more efficiently through the use of robots that lay bricks. As modular construction techniques become more prevalent, it is anticipated that the demand for bricklaying robots will increase.

Latest Trends

Bricklaying Robots Are Transforming Construction

Major market trends such as robotic arm systems, safety/human-robot collaboration, programming/adaptability, and data analytics optimization are shaping the global market for bricklaying robots. This emerging industry is anticipated to revolutionize the construction industry by automating the conventional building process, reducing labor costs, and accelerating the construction schedule.

Robotic Arm Systems Revolutionary

Robotic limb systems are an integral part of the market for bricklaying robots. These systems use robotic arms to precisely and efficiently place bricks, mortar, or other materials, allowing for efficiency and precision. By minimizing manual labor, injuries, and mistakes, robotic arm systems have revolutionized the construction industry. Companies such as FBR Limited, a global technology company, have developed a bricklaying robot dubbed "Hadrian X" that can lay 1,000 bricks per hour, thereby substantially reducing the construction time for walls.

Safe Collaboration in Robotic Bricklaying

Safety/human-robot collaboration is an additional crucial factor shaping the global market for bricklaying robots. Safety in the construction industry is crucial, and the introduction of robots necessitated the establishment of new safety measures to facilitate the secure collaboration of humans and robots. Collaborative robots, also known as "cobots," are able to work safely alongside humans. Companies such as Ekso Bionics, a manufacturer of robotic exoskeletons, developed a vest for bricklayers who would work with robotic arms to reduce back injuries and enable them to work without breaks.

Programming Adaptation for Bricklaying Robots

Programming/adaptability is another important trend shaping the global bricklaying robot market. The robots' programming is essential to their effective implementation. The code underlying the correct operation and decision-making abilities of these devices must be rigorously tested and adaptable to a variety of circumstances. Companies such as Kenneth Research have developed adaptive robot systems that use artificial intelligence algorithms to transform 2D construction plans into 3D robotic movements. This programming adapts to the environment and variables that may alter, such as environmental conditions, the robot's required work speed, and other variables.

Using Data Analytics to Improve Construction

Optimization of data analytics is the final trend shaping the global market for bricklaying robots. The optimization of constructing materials and their movement is crucial. These robots process immense quantities of data that must be analyzed and optimized for optimal work. Smart Asset Architecture utilizes algorithms that generate data-driven solutions to optimize construction material utilization and reduce costs.

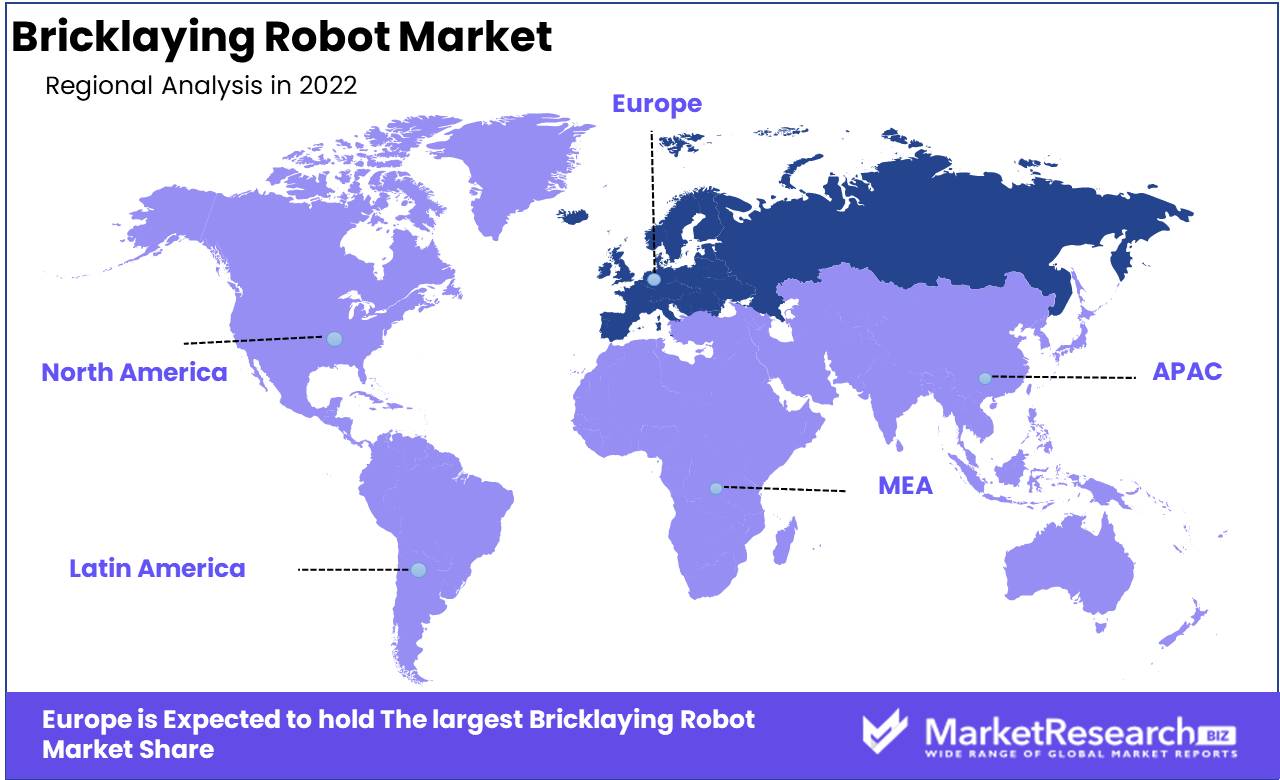

Regional Analysis

Europe dominates the market for bricklaying robots. As the construction industry continues to expand, new technologies have emerged to aid in enhancing efficiency and productivity. These innovations include bricklaying robots, which have revolutionized the construction of brick structures. In recent years, the market for these machines has expanded swiftly, with Europe emerging as the dominant force in this industry.

For decades, Europe has been at the forefront of technological innovation. The development of bricklaying robots is no different. Europe continues to be at the forefront of design, production, and sales for these machines, which made their debut in the region.

The market for bricklaying robots has gained significant traction in Europe as a result of the rising demand for construction projects and the need to improve productivity and reduce labor costs. The machines are designed to work quicker and more accurately than human labor, thereby reducing the potential for costly errors and delays. These advantages have made them very appealing to construction companies seeking to increase their productivity.

Europe's dominance in the market for bricklaying robots is primarily attributable to the region's emphasis on innovation and technology. In addition, European governments have supported the adoption of automation in the construction industry by providing funding and incentives to encourage investment in this area. This has allowed European companies to develop innovative and effective solutions that are transforming the building construction industry.

The shortage of skilled labor in the industry is one of the main factors propelling the adoption of bricklaying robots in Europe. Skilled bricklaying requires years of training and apprenticeship. This labor shortage has caused increased labor costs and construction project delays.

Key Regions and Countries

North America

- US

- Canada

- Mexico

Western Europe

- Germany

- France

- The UK

- Spain

- Italy

- Portugal

- Ireland

- Austria

- Switzerland

- Benelux

- Nordic

- Rest of Western Europe

Eastern Europe

- Russia

- Poland

- The Czech Republic

- Greece

- Rest of Eastern Europe

APAC

- China

- Japan

- South Korea

- India

- Australia & New Zealand

- Indonesia

- Malaysia

- Philippines

- Singapore

- Thailand

- Vietnam

- Rest of APAC

Latin America

- Brazil

- Colombia

- Chile

- Argentina

- Costa Rica

- Rest of Latin America

Middle East & Africa

- Algeria

- Egypt

- Israel

- Kuwait

- Nigeria

- Saudi Arabia

- South Africa

- Turkey

- United Arab Emirates

- Rest of MEA

Key Players Analysis

The global bricklaying robot market has grown significantly in recent years and is likely to expand more in the coming years. Several significant competitors are dominating the market with their diversified range of products and services.

FBR Limited, an Australian-based company that offers the Hadrian X bricklaying robot, is one of the market's main players. The robot can lay up to 1,000 bricks each hour, which is four to five times faster than a human bricklayer. Construction Robotics, a US-based company that offers the Semi-Automated Mason or SAM, is another significant contender. The robot is intended to assist human bricklayers with activities such as lifting and putting bricks.

MX3D, a Dutch robotics company that built the world's first entirely 3D-printed stainless steel bridge, and Fastbrick Robotics, an Australian-based company that offers a robotic brickwork system dubbed the FBR BrickBot, are two more companies making waves in the industry.

The growing demand for automation and robotics in the construction industry has fueled the expansion of the bricklaying robot market. These robots are becoming an interesting choice for construction organizations looking to enhance efficiency, cut labor costs, and complete projects faster.

Furthermore, the COVID-19 pandemic has increased the demand for automation in the construction industry, since social distancing restrictions and other restrictive measures have made it difficult to keep a full workforce on-site.

Top Key Players in the Bricklaying Robot Market

- FBR Ltd

- BROKK GLOBAL

- Autonomous Solutions Inc.

- Giant Hydraulic Tech

- CyBe Construction

- Ekso Bionics

- Fujita Corporation

- Conjet

- CYBERDYNE

- Other Key Players

Recent Development

- In 2019, The debut of robotic bricklaying systems. The introduction of autonomous bricklaying systems in the construction industry in 2019 marked a significant development 2019.

- In 2020, Bricklaying's Adoption of 3D Printing Technology With the advent of 3D printing technology in the year 2020, bricklaying reached a major milestone.

- In 2021, Bricklaying Augmented Reality (AR) Integration The adoption of augmented reality (AR) technology in bricklaying acquired momentum in 2021.

- In 2022, Sustainable Brick Material Development In 2022, there was a growing emphasis on eco-friendly building practices, which led to the creation of eco-friendly masonry materials.

- In 2023, Implementation of Blockchain for Brick Supply Chain Management Implementation of blockchain technology in the bricklaying industry, particularly in supply chain management, has recently acquired momentum.

Report Scope:

Report Features Description Market Value (2022) USD 84.0 Mn Forecast Revenue (2032) USD 205.3 Mn CAGR (2023-2032) 9.60% Base Year for Estimation 2022 Historic Period 2016-2022 Forecast Period 2023-2032 Report Coverage Revenue Forecast, Market Dynamics, COVID-19 Impact, Competitive Landscape, Recent Developments Segments Covered By Automation (Fully Autonomous, Semi-Autonomous), By Application (Residential Buildings, Commercial Buildings, Public Infrastructure, Nuclear Dismantling and Demolition, Other Applications) Regional Analysis North America – The US, Canada, & Mexico; Western Europe – Germany, France, The UK, Spain, Italy, Portugal, Ireland, Austria, Switzerland, Benelux, Nordic, & Rest of Western Europe; Eastern Europe – Russia, Poland, The Czech Republic, Greece, & Rest of Eastern Europe; APAC – China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Malaysia, Philippines, Singapore, Thailand, Vietnam, & Rest of APAC; Latin America – Brazil, Colombia, Chile, Argentina, Costa Rica, & Rest of Latin America; Middle East & Africa – Algeria, Egypt, Israel, Kuwait, Nigeria, Saudi Arabia, South Africa, Turkey, United Arab Emirates, & Rest of MEA Competitive Landscape FBR Ltd, BROKK GLOBAL, Autonomous Solutions Inc., Giant Hydraulic Tech, CyBe Construction, Ekso Bionics, Fujita Corporation, Conjet, CYBERDYNE, Other Key Players Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) -

-

- FBR Ltd

- BROKK GLOBAL

- Autonomous Solutions Inc.

- Giant Hydraulic Tech

- CyBe Construction

- Ekso Bionics

- Fujita Corporation

- Conjet

- CYBERDYNE

- Other Key Players