Breather Bags Market By Applications(Medical Devices, Pharmaceuticals, Other), By Product Type(Disposable Breather Bags, Reusable Breather Bags, Other), By Material(High-Density Polyethylene (HDPE), Polypropylene (PP), Other), By Region And Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, And Forecast 2023-2032

-

24576

-

Aug 2023

-

172

-

-

This report was compiled by Kalyani Khudsange Kalyani Khudsange is a Research Analyst at Prudour Pvt. Ltd. with 2.5 years of experience in market research and a strong technical background in Chemical Engineering and manufacturing. Correspondence Sr. Research Analyst Linkedin | Detailed Market research Methodology Our methodology involves a mix of primary research, including interviews with leading mental health experts, and secondary research from reputable medical journals and databases. View Detailed Methodology Page

-

Quick Navigation

Report Overview

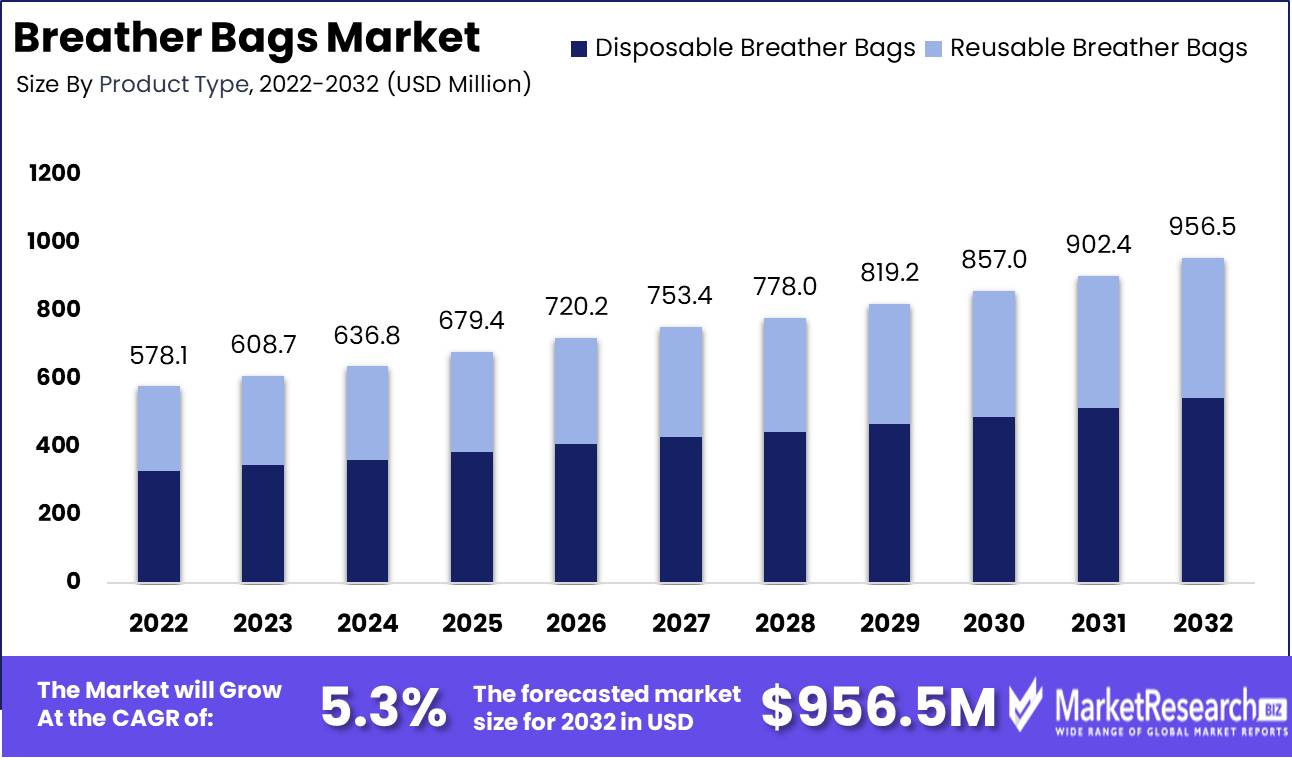

Breather Bags Market size is expected to be worth around USD 956.5 Mn by 2032 from USD 578.1 Mn in 2022, growing at a CAGR of 5.3% during the forecast period from 2023 to 2032.

Breather bags offer temporary aquatic housing for fish and water-dwelling creatures during transport. The permeable, thin plastic enables free flow of oxygen and carbon dioxide molecules. Oxygen molecules from air can pass through the plastic walls into the water, replenishing oxygen supply.

Meanwhile, carbon dioxide waste from the animals diffuses out. Through this gas exchange, the bags create a livable environment so the animals can breathe with ease while in transit. Although made of plastic, the bags function more like gills - providing fresh oxygen and removing carbon dioxide. This keeps fish and invertebrates alive until they can be safely released into permanent housing.

In recent years, the global Breather Bags Market has seen steady growth driven by several key factors. Expanding manufacturing, especially in emerging markets, has increased demand for transit and warehouse protective packaging like breather bags. Just-in-time inventory management has also made barrier packaging critical for maintaining product integrity across complex supply chains.

Moreover, e-commerce's rapid growth has led to more direct-to-consumer shipping. This creates need for packaging preventing moisture and oxygen damage. Breather bags offer permeable protection that traditional plastic wraps cannot. Additionally, their reusability supports sustainability initiatives in packaging.

Recent Factors shaping the breather bags market include:

- Sustainability initiatives drive demand for compostable or partly recycled constructions using plant-based biomaterials.

- Active and intelligent packaging features have grown, including moisture absorption pads, oxygen scavengers, and smart sensors for tracking conditions.

- Optimization occurs for expanding cold chain logistics, especially in Asia Pacific and South America. There, infrastructure build-outs support frozen and refrigerated goods transport.

- Integration of features like RFID tagging enables automation and digitization across supplier networks and warehouse management systems.

Driving factors

Expanding Manufacturing and Supply Chains

Breather bags market growth results from rapid expansion of manufacturing and global supply chains. As production scales internationally, more components and finished goods ship across borders over longer distances. This heightens the need for protective packaging that maintains product integrity during complex transportation and storage.

Breather bags provide optimal moisture and oxygen damage barrier solutions while allowing contents to ventilate. Their durability and reusability also make them cost-effective for high-volume manufacturing.

Just-In-Time Inventory Management

Lean manufacturing practices like just-in-time inventory require packaging preserving component quality with minimal warehousing. Breather bags limit moisture accumulation and oxidation during storage that could degrade sensitive parts and electronics before production. Their puncture and tear resistance also vitally protects components through repetitive handling. By enabling just-in-time component delivery in peak condition, breather bags support streamlined manufacturing workflows.

Sustainability Initiatives

As companies adopt sustainability initiatives targeting packaging waste reduction, breather bags' reusability and recyclability become appealing. They support corporate goals to reduce single-use plastics and disposables. New compostable designs using plant-based materials further lower environmental impact. Breather bags' smaller footprint also improves transport efficiency over rigid containers. Their green advantages align with consumer preferences for eco-friendly packaging.

Restraining Factors

Plastic Resin Price Volatility

Most breather bags use plastics like polyethylene, nylon, and polypropylene in construction. Global petrochemical and plastic resin price volatility poses challenges to breather bag suppliers in maintaining stable profit margins. When input costs rise, vendors may need to raise prices, potentially suppressing demand. Unpredictable resin pricing swings complicate production planning. Companies should implement hedging and long-term contract strategies to control costs.

Competition from Rigid Packaging

While permeable, breather bags face competition from more rigid options like plastic cases and metal cans. These provide even better barrier properties for highly sensitive contents. Their durability also makes rigid containers suitable for multiple trips and extensive reuse. However, their heavier weight increases transportation costs, while breather bags' flexibility and stackability confer logistics advantages. Vendors should promote superior moisture control and weight savings to expand market share versus rigid containers.

Application Analysis

The medical devices industry accounts for the largest breather bags market share, estimated at around 35% as of 2022. Several factors drive this application segment's dominance. First, medical devices often contain fragile sensitive materials like metals, plastics, and electronics vulnerable to moisture damage during shipping and storage. Breather bags provide permeable protection preventing condensation buildup and corrosion that could compromise expensive medical equipment.

Additionally, many medical devices require sterilization after packaging using ethylene oxide or radiation. Breather bags' breathable materials allow these sterilization methods to penetrate packaging and effectively treat contents without losing barrier properties. This ability to enable sterilization while maintaining a contaminant-free environment proves critical.

Product Type Analysis

Disposable breather bags account for the majority global market share, estimated over 60% as of 2021. The convenience and flexibility of single-use disposable designs make them well-suited for high-volume packaging operations across industries.

A key advantage is disposable bags eliminate the cleaning and sterilization need associated with reusable rigid containers. This avoids contamination risks while increasing packaging line speeds and efficiency. Disposable bags can rapidly integrate into automated packing systems. They also reduce return logistics and reusable container reconditioning operational costs.

Disposable breather bags suit the on-demand flexibility modern supply chains require. Manufacturers can swiftly scale packaging up or down as production volumes change. Their lightweight also incurs lower shipping costs compared to heavy-duty reusable designs.

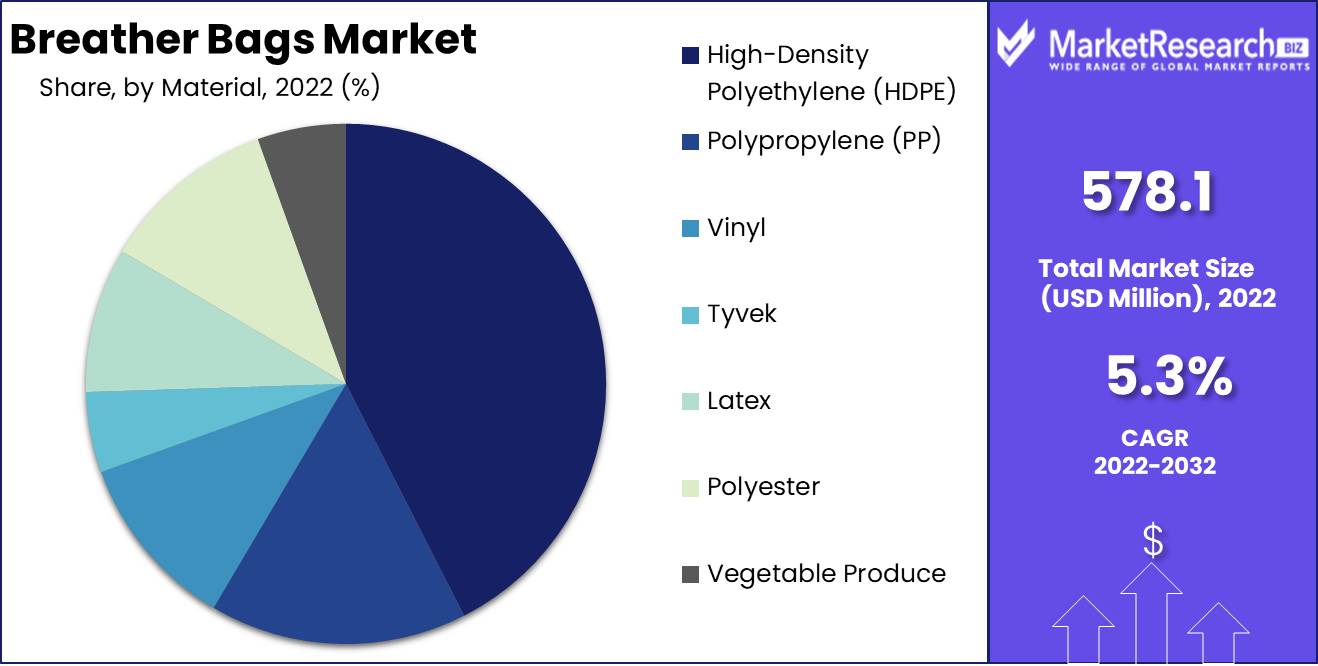

Material Analysis

High-density polyethylene (HDPE) accounts for the largest breather bags market material share, estimated over 40% as of 2022. HDPE offers an optimal balance of barrier properties, durability, and cost-effectiveness making it well-suited for breather bag production.

HDPE provides good moisture and oxygen barrier properties while allowing sufficient permeability for breathability. This protects against condensation and oxidation without excess humidity buildup. HDPE bags maintain an ideal internal packaging environment.

High-density polyethylene exhibits high tensile strength and impact resistance even at low thicknesses. This results in durable, puncture-resistant breather bags withstanding potential transport and handling hazards. HDPE toughness protects contents without requiring excessive material use.

Key Market Segments

Applications Analysis

- Medical Devices

- Pharmaceuticals

- Aquatic Livestock

- Hospital Sterilization

- Cleaning Units

- Sterilized Supplies

- Surgical Packs

- Anesthesia Machines

Product Type Analysis

- Disposable Breather Bags

- Reusable Breather Bags

Material Analysis

- High-Density Polyethylene (HDPE)

- Polypropylene (PP)

- Vinyl

- Tyvek

- Latex

- Polyester

- Vegetable Produce

Growth Opportunity

Expanding Cold Chain Logistics

Cold chain logistics grows over 6% annually to meet rising temperature-controlled transport demand for foods, pharmaceuticals, and other perishables. This creates substantial demand for breather bags maintaining strict temperature control across cold supply chains. Vendors enhance designs with insulating materials, phase change gels, and temperature monitors to tap this growth.

E-Commerce Boom

Rapid e-commerce and direct-to-consumer shipping growth require more protective mailers and packaging like breather bags. Online retail surged during the pandemic, accelerating breather bags demand for secure doorstep delivery. Their puncture resistance prevents damage while breathability prevents moisture accumulation that could ruin electronics, foods, and other e-commerce products.

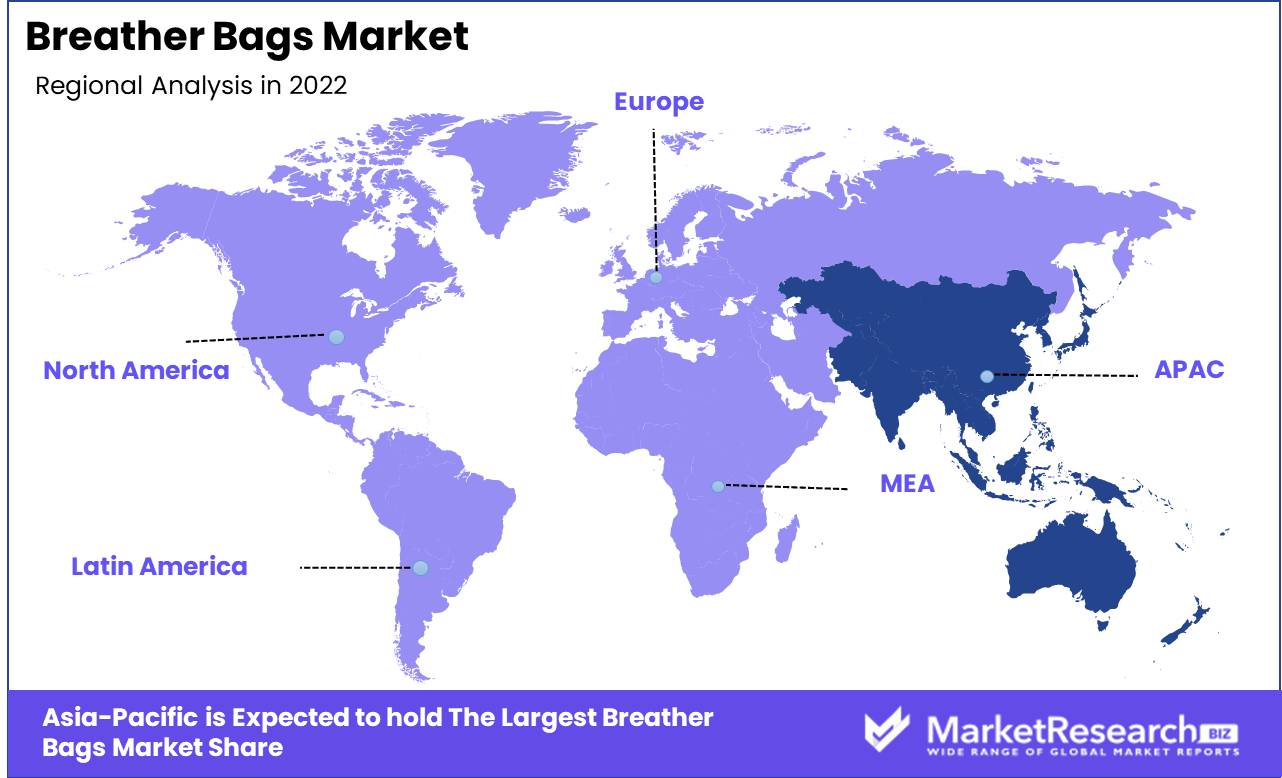

Regional Analysis

The Asia Pacific region has firmly established its dominance in the global breather bags market, showcasing remarkable growth and influencing the industry's trajectory. This market, which pertains to the packaging sector, has experienced a significant shift towards the Asia Pacific region due to several key factors.

Firstly, the Asia Pacific region boasts a thriving manufacturing sector, encompassing diverse industries such as electronics, pharmaceuticals, and food products. These industries heavily rely on breather bags to protect their sensitive products from moisture and contaminants during transportation and storage. This heightened demand for reliable packaging solutions has led to a surge in the adoption of breather bags across the region.

The Asia Pacific region is home to some of the world's fastest-growing economies, including China, India, and Southeast Asian countries. As these economies expand, the need for advanced packaging solutions also escalates, thereby driving the breather bags market's growth. The region's robust e-commerce industry further amplifies this demand, as the safe delivery of goods to consumers remains a paramount concern.

Key Regions and Countries

North America

- US

- Canada

- Mexico

Western Europe

- Germany

- France

- The UK

- Spain

- Italy

- Portugal

- Ireland

- Austria

- Switzerland

- Benelux

- Nordic

- Rest of Western Europe

Eastern Europe

- Russia

- Poland

- The Czech Republic

- Greece

- Rest of Eastern Europe

APAC

- China

- Japan

- South Korea

- India

- Australia & New Zealand

- Indonesia

- Malaysia

- Philippines

- Singapore

- Thailand

- Vietnam

- Rest of APAC

Latin America

- Brazil

- Colombia

- Chile

- Argentina

- Costa Rica

- Rest of Latin America

Middle East & Africa

- Algeria

- Egypt

- Israel

- Kuwait

- Nigeria

- Saudi Arabia

- South Africa

- Turkey

- United Arab Emirates

- Rest of MEA

Key Players Analysis

Amcor, This packaging industry giant provides a wide breather bags portfolio spanning high-barrier medical and pharmaceutical applications to multilayer bags for food transport. Amcor leverages global scale and advanced film technology to develop cost-effective breather bag solutions.

Sorbent Systems, A major US-based provider specializing in desiccant breather bags and other moisture control packaging. Their adsorbent bags offer superior humidity and condensation protection for electronics, diagnostics, and industrial uses.

Bemis Company, Acquired by Amcor in 2019, Bemis was a top producer of breather bags designed specifically for medical device transport and distribution requirements. Their expertise in medical packaging makes them a leader.

Dou Yee, A Singapore-based company focused on highly precise breather bags for electronics and semiconductor shipping. Dou Yee provides extensive custom bag design and runs fully optimized ISO cleanroom production facilities.

Top Key Players in Breather Bags Market

- Amcor

- Bemis Company

- Berry Global

- Mondi

- Sealed Air

- Smurfit Kappa

- Coveris

- Huhtamäki Oyj

- Constantia Flexibles

- WINPAK

Recent Development

- In 2022, Amcor opened a new packaging innovation center in Jakarta, Indonesia focusing on more sustainable breather bags and other packaging technology.

- In 2022, Dou Yee announced a materials partnership with Dow Chemical to develop high-performance polyethylene breather bag films.

- In 2021, Sorbent Systems launched the Halotron breather bag line with a proprietary gas mixture allowing safe use around sensitive electronics.

- In 2021, Daash Cellpack commissioned a new ISO Class 8 cleanroom breather bag production line for electronics industry customers.

Report Scope

Report Features Description Market Value (2022) USD 578.1 Mn Forecast Revenue (2032) USD 956.5 Mn CAGR (2023-2032) 5.3% Base Year for Estimation 2022 Historic Period 2016-2022 Forecast Period 2023-2032 Report Coverage Revenue Forecast, Market Dynamics, COVID-19 Impact, Competitive Landscape, Recent Developments Segments Covered Applications(Medical Devices, Pharmaceuticals, Other), Product Type(Disposable Breather Bags, Reusable Breather Bags, Other), Material(High-Density Polyethylene (HDPE), Polypropylene (PP), Other) Regional Analysis North America – The US, Canada, & Mexico; Western Europe – Germany, France, The UK, Spain, Italy, Portugal, Ireland, Austria, Switzerland, Benelux, Nordic, & Rest of Western Europe; Eastern Europe – Russia, Poland, The Czech Republic, Greece, & Rest of Eastern Europe; APAC – China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Malaysia, Philippines, Singapore, Thailand, Vietnam, & Rest of APAC; Latin America – Brazil, Colombia, Chile, Argentina, Costa Rica, & Rest of Latin America; Middle East & Africa – Algeria, Egypt, Israel, Kuwait, Nigeria, Saudi Arabia, South Africa, Turkey, United Arab Emirates, & Rest of MEA Competitive Landscape Amcor, Bemis Company, Berry Global, Mondi, Sealed Air, Smurfit Kappa, Coveris, Huhtamäki Oyj, Constantia Flexibles, WINPAK Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for: Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) -

-

- Amcor

- Bemis Company

- Berry Global

- Mondi

- Sealed Air

- Smurfit Kappa

- Coveris

- Huhtamäki Oyj

- Constantia Flexibles

- WINPAK