Aluminium Powder Market By Type (Atomized Aluminium Powder, Flake Aluminium Powder), By Application (Industrial, Automotive, Aerospace & Defense, Building & Construction, Electronics & Semiconductors, Others) By Region And Companies - Industry Segment Outlook, Market Assessment, Competition Scenario, Trends, And Forecast 2024-2033

-

43523

-

Jan 2022

-

171

-

-

This report was compiled by Shreyas Rokade Shreyas Rokade is a seasoned Research Analyst with CMFE, bringing extensive expertise in market research and consulting, with a strong background in Chemical Engineering. Correspondence Team Lead-CMFE Linkedin | Detailed Market research Methodology Our methodology involves a mix of primary research, including interviews with leading mental health experts, and secondary research from reputable medical journals and databases. View Detailed Methodology Page

-

Quick Navigation

- Aluminium Powder Market Size, Share, Trends Analysis

- Driving Factors

- Restraining Factors

- Aluminium Powder Market Segmentation Analysis

- Industry Segments

- Growth Opportunities

- Aluminium Powder Market Regional Analysis

- Industry By Region

- Aluminium Powder Market Key Player Analysis

- Industry Key Players

- Recent Development

- Report Scope

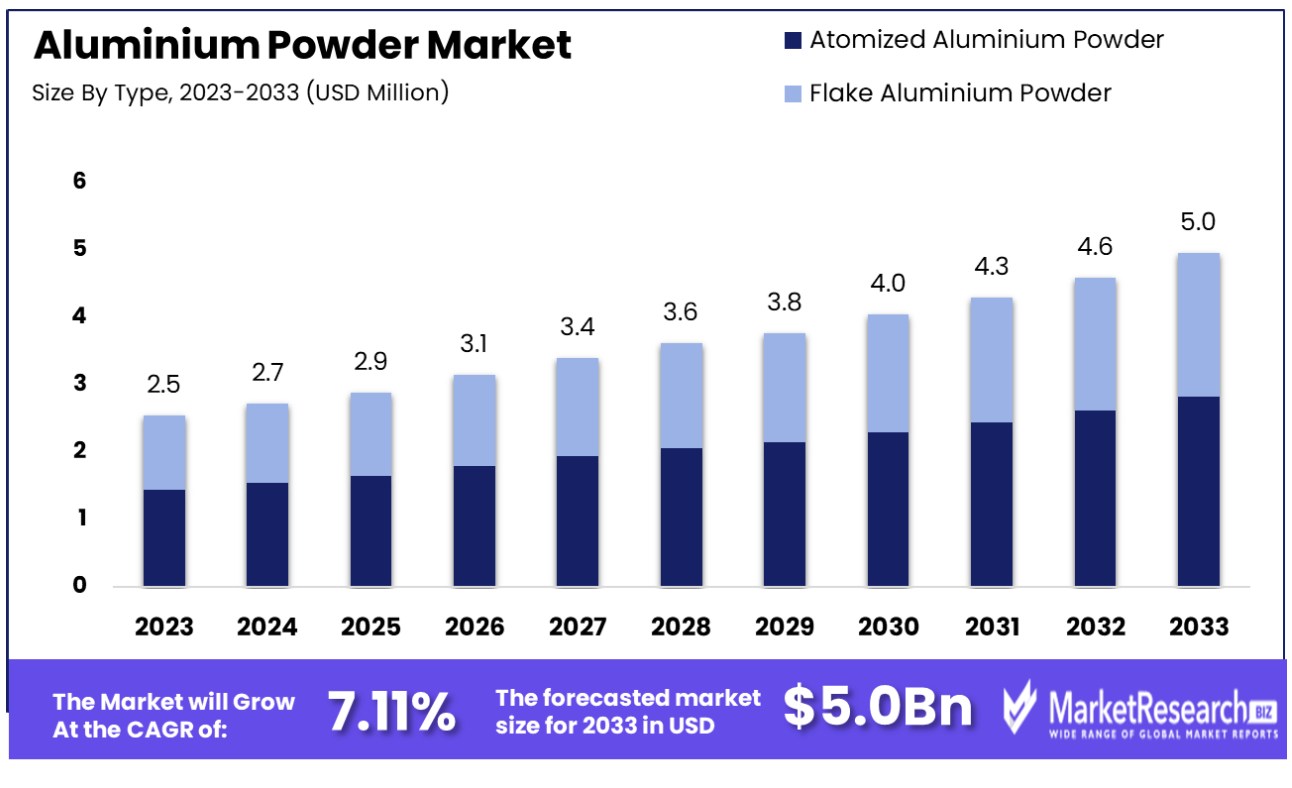

The Aluminium Powder Market was valued at 2.5 Bn in 2022. It is expected to reach 5.0 Bn by 2032, with a CAGR of 7.11% during the forecast period from 2023 to 2033.

The surge in demand in the construction sector and the production of solar cells are some of the main driving factors for the aluminum powder market expansion. Aluminum powder is known as aluminum flake, metal, and metana. It is light, white to gray, with no smell of powder. Aluminum powder is a highly flammable product. It is a fine granulated powder which is made from aluminum.

These are also used in several applications like the production of slurry, explosives, and detonators, thermit method is used for manufacturing Ferro alloys and for customized welding applications like rails, pyrotechnic production of crackers, sparkles, and other pyrotechnic items, the production of aluminum paste, paints and many powder elements used in automobiles.

Aluminum powder has one of the most common properties that experiences a dynamic exothermic response when it gets oxidized and finds applications in pyrotechnic methods. These are also used in deoxidants and exothermic tapping elements to raise the yielding of casting. Aluminum powders are used in paints, pigment coating, protective shield coating, printing inks, rocket fuels, and ceramics.

The use of inorganic and organic chemicals as catalysts. Pyro powders are combined with carbon and are used in the production of fireworks. The aluminum coarse powder is used in thermite response. In the food industry, aluminum powder is used as a food additive that has been consumed in food manufacturing for many centuries. Risers, stabilizers, anti-clumping agents, etc. are used in foods in several regions. Aluminum is found in the foods in their natural state of form.

In the medical industry, aluminum powder was commonly used due to its chemical elements and hardness. For example, aluminum powder is a component that is used for prosthetic limbs and alternatives to prosthetic eyes. These are also used in dental crowns, tooth implants, and others. As it has non-corrosive features, aluminum powder is best used on most of the products and infrastructure in a hospital.

Due to its lightweight feature, it makes an ideal choice in medical equipment for easy transportation. The demand for aluminum powder will increase due to the benefits of the capability to cause oxidation-decrease reactions that can release huge amounts of thermal reactions that will help in market expansion in the coming years.

Driving Factors

Photovoltaic Industry Boosts Aluminum Powder Use

The expansion of the photovoltaic electronic paste industry marks a significant milestone, contributing substantially to the escalating demand for aluminum powder. This powder is indispensable in the production of conductive pastes, a fundamental component in the fabrication of solar cells, which are at the heart of photovoltaic technology. As the global pivot towards renewable energy sources intensifies, and solar technology becomes increasingly prevalent, there's a consequent surge in the need for high-grade aluminum powder. This uptick is not merely a trend but a robust driver of market growth, as the quality and efficiency of photovoltaic solutions become paramount.

Technological Advancements Expand Aluminum Powder Applications

Ongoing technological advancements in industries like automotive, aerospace, and construction led to the development of new aluminum powder products with enhanced properties. These innovations include improved powder metallurgy techniques and specialized alloy formulations, expanding aluminum powder's applications and performance capabilities. The ripple effect of these advancements broadens the spectrum of applications for aluminum powder, pushing the boundaries of its capabilities and utility. Industries are not just passive recipients but active seekers of materials that promise superior performance and efficiency.

Solar Energy Adoption Fuels Aluminum Powder Demand

Aluminum powder, as a key component in the fabrication of solar cells, sees increased demand with the rising adoption of solar energy. The global push towards sustainable and renewable energy sources places solar technology at the forefront of this transition. As more individuals and industries adopt solar solutions, the demand for aluminum powder, essential for producing efficient and effective solar cells, surges, contributing to the market's expansion and evolution. This material is not merely a component but a cornerstone in producing efficient and effective solar cells. The burgeoning adoption of solar technology doesn't just reflect an environmental trend; it signifies a profound shift in energy paradigms. Consequently

Restraining Factors

Fluctuations in Raw Material Prices Impact Aluminium Powder Market Growth

Fluctuations in raw material prices, such as bauxite and alumina, can significantly impact the cost of aluminum powder and affect its market growth. The prices of these raw materials are subject to global market dynamics, including changes in supply and demand, trade policies, and geopolitical events.

When the costs of bauxite and alumina rise, the production costs for aluminum powder increase, potentially leading to higher prices for end-users. This volatility can deter purchasers, particularly in cost-sensitive industries, and can lead to a decrease in demand, thereby restraining market growth.

Market Maturity Limits Growth Opportunities for Aluminium Powder

The aluminum powder market is mature, with limited opportunities for new product development, which can restrain its growth. As a well-established market, many applications and technologies utilizing aluminum powder are already developed and widely adopted.

This maturity means there are fewer gaps in the market for innovative products, making it challenging for manufacturers to create distinctive, value-added products that can stimulate additional demand. In such a mature market, competition is often based on price rather than innovation, leading to increased pressure on margins and potentially stifling further investment in new product development. This scenario can lead to slower growth rates and limited market expansion.

Aluminium Powder Market Segmentation Analysis

By Type Analysis :

Atomized Aluminum Powder is recognized as the dominant segment within the aluminum powder market. This type of powder is produced through the atomization process, which involves melting aluminum into a liquid state and then spraying it into fine granules. The resulting atomized aluminum powder offers a uniform and consistent particle size, making it highly desirable for a wide range of industrial applications.

Its versatility and adaptability have led to extensive use in applications ranging from pyrotechnics and paints to metallurgy and advanced materials. While Atomized Aluminum Powder leads the market due to its broad applicability and superior properties, Flake Aluminum Powder is also significant, particularly valued in applications requiring a larger surface area and unique flake-like morphology, such as in certain types of coatings, pigments, and conductive materials.

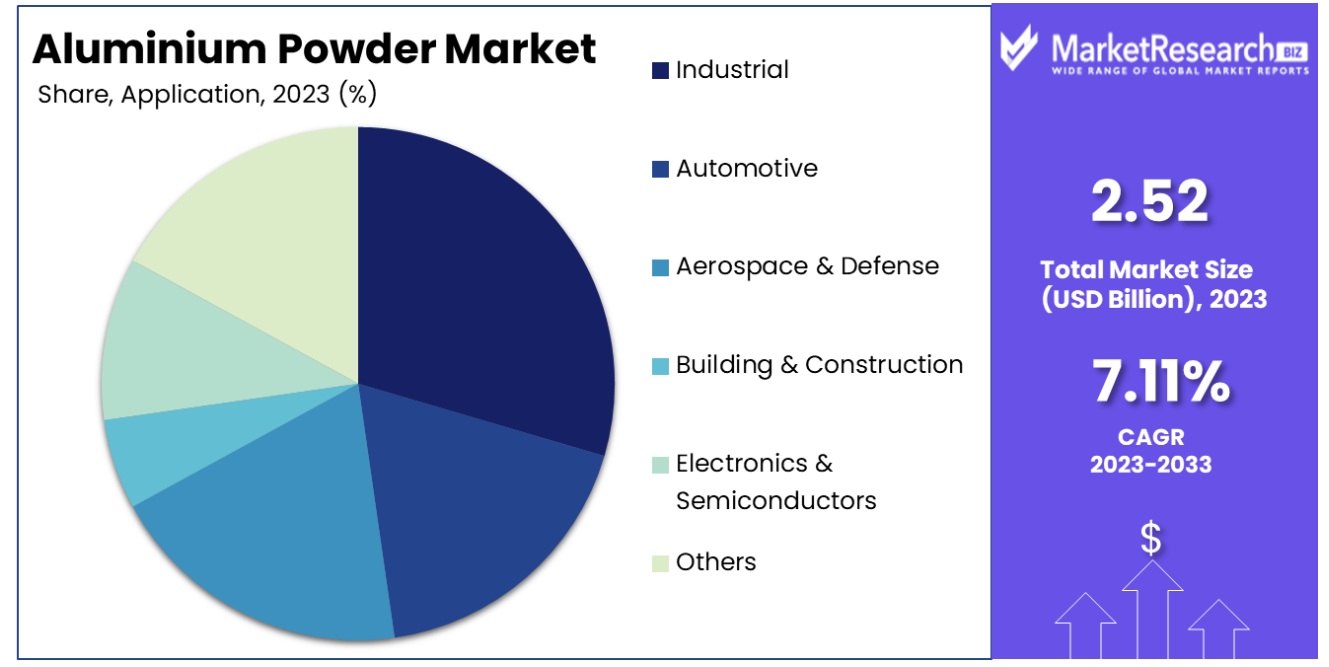

By Application Analysis:

Industrial applications for aluminum powder have long been its main application area. Here, it can be found being utilized for many purposes such as paints and coatings applications as well as raw material use in chemical processes. Aluminum powder's widespread industrial usage stems from its versatility and reactivity; acting as a reducing agent in metalworking and producing lightweight concrete are just two uses that illustrate its use as a reducing agent. Aluminum's versatility also makes it invaluable in various industrial processes.

While industrial applications of aluminum powder remain dominant, other sectors including Automotive, Aerospace & Defense, Building & Construction and Electronics & Semiconductors also utilize it in significant volumes. Automotive and Aerospace & Defense both utilize aluminum powder to manufacture lightweight yet strong components. Building and Construction use aluminum powder in applications like aerated concrete blocks for insulation and structure. Electronics & Semiconductors take advantage of its conductive properties by employing it in electronic components and devices.

Industry Segments

By Type:

- Atomized Aluminium Powder

- Flake Aluminium Powder

By Application:

- Industrial

- Automotive

- Aerospace & Defense

- Building & Construction

- Electronics & Semiconductors

- Others

Growth Opportunities

Paint and Pigment Industry Drives Aluminum Powder Market

The paint and pigment industries are among the biggest consumers of aluminium powder, contributing to its market expansion. Aluminium powder is used in paints and coatings due to its reflective and protective properties such as imparting metallic sheen to surfaces while offering corrosion and UV radiation resistance. As construction and manufacturing sectors expand further, demand for aluminum-containing paints and coatings grows, reflecting an expansion driven by demand from industries needing durable yet aesthetically pleasing applications for coatings made of this substance.

Aluminium Powder Market Regional Analysis

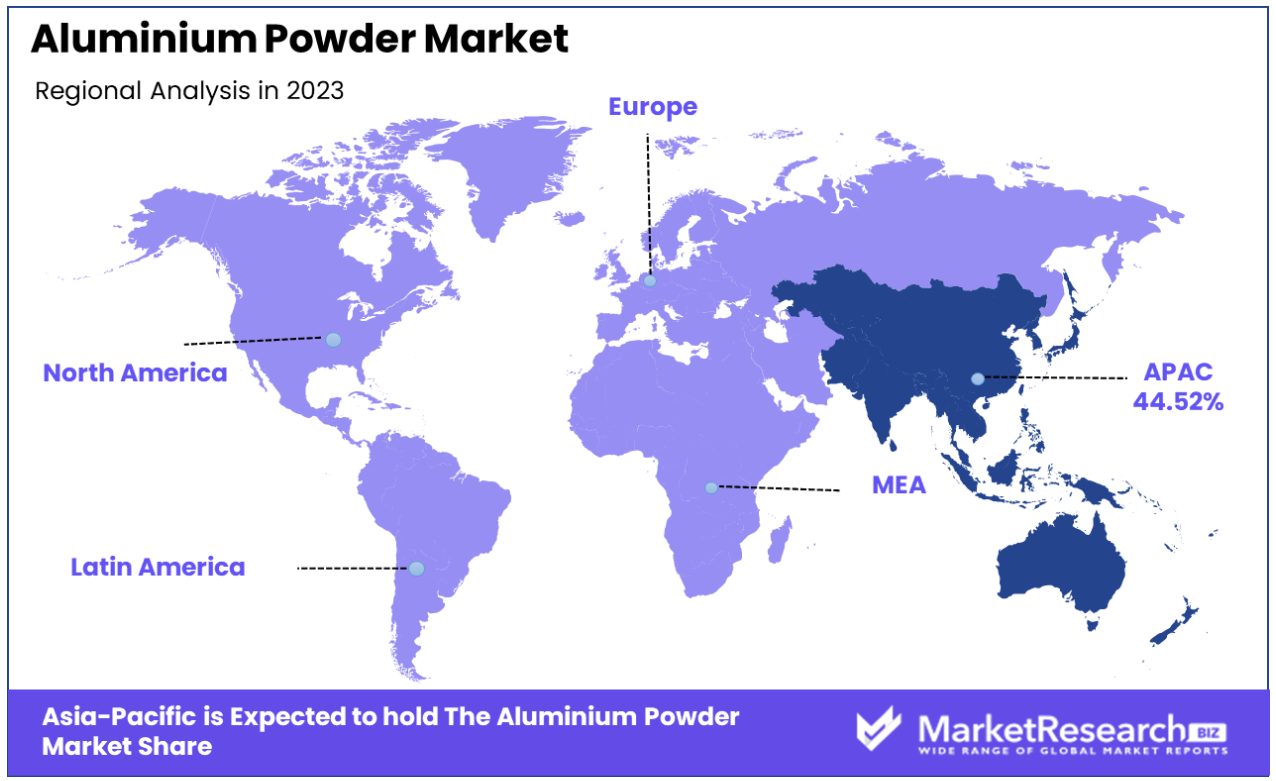

Asia-Pacific Dominates with 44.52% Market Share in Aluminium Powder Market

Asia-Pacific holds a significant 44.52% market share for aluminium powder sales, due to the region's robust industrial growth - particularly within manufacturing and construction. Countries like China, India, and Japan are leading consumers and producers of aluminum powder, owing to their extensive use in the automotive, aerospace, fireworks, and construction industries.

The region's cost-competitive manufacturing environment, coupled with the availability of raw materials and labor, significantly contributes to this market dominance. Aluminum powder market growth in Asia-Pacific is driven by rising demand for lightweight materials in the automotive and aerospace sectors, driving demand for aluminum powder.

The market dynamics in Asia-Pacific are influenced by the region's expanding economic development and industrialization. The growing emphasis on infrastructure development and the rising demand for consumer products that use aluminum powder, such as paints and pigments, drive market growth. Furthermore, the region's inclination towards energy efficiency and sustainable practices is leading to innovations in aluminum powder applications, particularly in solar cells and lightweight materials.

North America: Advanced Technologies and High-Quality Standards

North America's aluminum powder market is driven by advanced technologies and high-quality standards. The region's strong focus on research and development leads to high-end applications in the aerospace and automotive sectors. Aluminum powder has become an indispensable material in various industrial applications due to its lightweight and strong nature, prompting demand.

Europe: Focus on Innovation and Environmental Sustainability

Europe’s aluminum powder market is characterized by a focus on innovation and environmental sustainability. The region's stringent environmental regulations drive the demand for eco-friendly and efficient materials. Europe’s well-established automotive and aerospace industries, combined with the growing renewable energy sector, provide substantial opportunities for the aluminum powder market. The commitment to maintaining high industrial standards and the emphasis on sustainable practices are expected to continue driving the market in Europe.

Industry By Region

North America

- The US

- Canada

- Rest of North America

Europe

- Germany

- France

- The UK

- Spain

- Italy

- Russia

- Netherlands

- Rest of Europe

Asia-Pacific

- China

- Japan

- South Korea

- India

- New Zealand

- Singapore

- Thailand

- Vietnam

- Rest of Asia Pacific

Latin America

- Brazil

- Mexico

- Rest of Latin America

Middle East & Africa

- South Africa

- Saudi Arabia

- UAE

- Rest of the Middle East & Africa

Aluminium Powder Market Key Player Analysis

Aluminium Powder Market companies listed here play a vital role in driving market expansion and innovation. AMG Advanced Metallurgical Group NV and Alcoa Corporation are industry leaders, known for their extensive production capabilities and high-quality aluminum powder, significantly influencing supply chains and pricing dynamics.

Ampal Inc., Valimet, Inc., and Henan Yuanyang Powder Technology Co., LTD., are key players with a strong focus on specialized aluminum powders, catering to diverse applications from pyrotechnics to additive manufacturing. Their strategic positioning emphasizes product quality and customization, reflecting the industry's shift towards more specialized and high-performance materials.

Industry Key Players

- AMG Advanced Metallurgical Group NV

- Ampal Inc.

- Valimet, Inc.

- Avl Metal Powders n.v.

- Henan Yuanyang Powder Technology Co., LTD.

- Angang Group Aluminium Powder Co., Ltd

- NovaCentrix

- MMP Industries Limited

- Schlenk Se

- m-tec powder GmbH

- PARTER Capital Group AG

- Alcoa Corporation

Recent Development

- June 2023: m-tec powder GmbH invested to expand its production capacity of the product in South Africa. With the new investment plan, the company intended to increase production capacities for gas- and air-atomized aluminum powders and aluminum-alloy powders.

Report Scope

Report Features Description Market Value (2023) USD 2.5 Billion Forecast Revenue (2033) USD 5.0 Billion CAGR (2024-2032) 7.11% Base Year for Estimation 2023 Historic Period 2016-2023 Forecast Period 2024-2033 Report Coverage Revenue Forecast, Market Dynamics, COVID-19 Impact, Competitive Landscape, Recent Developments Segments Covered By Type (Atomized Aluminium Powder, Flake Aluminium Powder), By Application (Industrial, Automotive, Aerospace & Defense, Building & Construction, Electronics & Semiconductors, Others) Regional Analysis North America - The US, Canada, Rest of North America, Europe - Germany, France, The UK, Spain, Italy, Russia, Netherlands, Rest of Europe, Asia-Pacific - China, Japan, South Korea, India, New Zealand, Singapore, Thailand, Vietnam, Rest of Asia Pacific, Latin America - Brazil, Mexico, Rest of Latin America, Middle East & Africa - South Africa, Saudi Arabia, UAE, Rest of Middle East & Africa Competitive Landscape AMG Advanced Metallurgical Group NV, Ampal Inc., Valimet, Inc., Avl Metal Powders n.v., Henan Yuanyang Powder Technology Co., LTD., Angang Group Aluminium Powder Co., Ltd, NovaCentrix, MMP Industries Limited, Schlenk Se, m-tec powder GmbH, PARTER Capital Group AG, Alcoa Corporation Customization Scope Customization for segments, region/country-level will be provided. Moreover, additional customization can be done based on the requirements. Purchase Options We have three licenses to opt for Single User License, Multi-User License (Up to 5 Users), Corporate Use License (Unlimited User and Printable PDF) -

-